High Density Best Quality Geomembrane with Us 230 Geotextile Price as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description

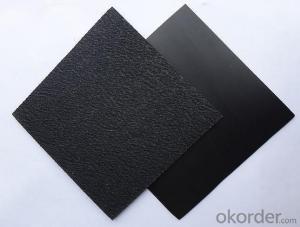

(middle) density polyethylene geomembrane is made from HDPE resin

And additives such as antioxidant, light-stabilize and carbon black, etc. It is extensively used for landfills, sewages, mining, environmental protections and irrigation projects.

1. Product Introduction

Thickness

1mm-3.0mm

width

4-9m

Length

50-100m or as customers' requests

Material

LDPE, LLDPE, HDPE, EVA, ECB, PVC , CPE

Color

Black, white, green, blue, red, grey, and others

Port

Qingdao

Delivery

2-20 days

Packing

woven bag or as customers' requests

Application:

It can be widely used in areas of garbage burying, waste disposal, tail minerals storage and underground construction projects.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help with vegetation establishment in landscaping projects?

- Geotextiles help with vegetation establishment in landscaping projects by providing a stable and supportive environment for plant growth. They act as a barrier, preventing erosion and soil movement, while allowing water and nutrients to pass through to the plants' root systems. Geotextiles also aid in weed suppression, creating a favorable condition for the establishment and growth of desired vegetation.

- Q: What are the factors to consider when designing geotextile-reinforced structures?

- When designing geotextile-reinforced structures, there are several factors that need to be considered. Firstly, the type and properties of the geotextile being used must be evaluated, including its strength, durability, and permeability. The soil conditions at the site, such as its composition, stability, and drainage characteristics, also play a significant role. The design should take into account the anticipated loads and stresses that the structure will be subjected to, as well as any potential environmental factors such as rainfall or seismic activity. Additionally, construction considerations, including the installation process, available equipment, and cost-effectiveness, should be taken into account. Overall, a comprehensive understanding of the site conditions, geotextile properties, and design requirements is crucial to ensure the successful and sustainable design of geotextile-reinforced structures.

- Q: How are geotextiles maintained?

- Geotextiles are typically low-maintenance materials that require minimal upkeep. Routine maintenance for geotextiles involves inspecting them periodically to ensure they are functioning properly and remain free from any damage or clogging. If any issues or damage are identified, appropriate repairs or replacements may be necessary. Overall, geotextiles are designed to be durable and long-lasting, requiring little ongoing maintenance.

- Q: Can geotextiles be recycled?

- Yes, geotextiles can be recycled. They are typically made of synthetic materials such as polyester or polypropylene, which can be melted down and processed into new products. Recycling geotextiles helps to reduce waste and minimize the environmental impact of these materials.

- Q: There are engineering budgets

- Geotextile to polypropylene or polyester and other chemical fiber made of raw materials, to acid and alkali, no corrosion, no moth, anti-oxidation. It is widely used in the field of civil engineering, its main application areas are: 1. Highway, railway, airport, building and other engineering foundation reinforcement treatment; use of geotextile to enhance the soil tensile strength and resistance to deformation, Concentrate the stress spread, transfer or decomposition, to prevent the soil by external force and damage. Enhance the stability of the building structure to improve soil quality. 2. dam and other slope protection project; the use of geotextile good permeability and water permeability, so that water flow through, and thus effectively cut off the loss of sand. Geotextile mesh should not be blocked - due to the formation of amorphous fibrous tissue structure and strain and mobility. Has a good conductivity of water, it can make the formation of drainage within the soil channel, the soil structure of excess liquid and gas exclusion. 3 .. road maintenance works; the use of geotextile isolation characteristics to prevent the upper and lower gravel, soil and concrete mixed between. If you really have the confidence to do sales I can try to support the specific telephone consultation Yinjing Li

- Q: What are the advantages of using geotextiles in green building design?

- Geotextiles offer numerous advantages in green building design. Firstly, they provide effective erosion control by stabilizing soil, preventing sediment runoff, and reducing the need for traditional erosion control measures. Additionally, geotextiles enhance water filtration and drainage, promoting healthier soil and preventing waterlogging. These materials also aid in weed control, reducing the need for herbicides and minimizing maintenance efforts. Moreover, geotextiles can improve the structural integrity of green building projects by reinforcing soil and preventing subsidence. Lastly, they offer a sustainable solution as they are typically made from recycled materials and can be reused or recycled themselves.

- Q: Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, while retaining soil particles. This helps to create a drainage pathway, preventing water buildup and reducing the pressure exerted on the soil.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- The guidelines for geotextile installation in erosion control projects may vary depending on the specific project and site conditions. However, some common guidelines include conducting a thorough site assessment, properly preparing the subgrade, ensuring proper overlap and seam strength of geotextile materials, adequately anchoring the geotextile to prevent movement, and regularly inspecting and maintaining the geotextile for any damages or clogging. Additionally, following manufacturer recommendations and consulting with experienced professionals can also provide valuable insights for successful geotextile installation in erosion control projects.

- Q: 400 grams per square meter of non-woven geotextiles how much money

- According to your technical parameters, the specific number of professional geotextile manufacturers to answer, power to discuss!

Send your message to us

High Density Best Quality Geomembrane with Us 230 Geotextile Price as Waterproof Facing of Earth and Rockfill Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords