High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Applied Field of High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

1) Power Plant, 2) Mineral Processing, 3) Refractory Factory, 4) Cement Plant

2. The Size and Chemical Composition of High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø20 | 0.0322 | 31056 |

2 | Ø25 | 0.063 | 15873 |

3 | Ø30 | 0.11 | 9091 |

4 | Ø40 | 0.257 | 3891 |

5 | Ø50 | 0.50 | 2000 |

6 | Ø60 | 0.867 | 1153 |

7 | Ø70 | 1.37 | 729 |

8 | Ø80 | 2.05 | 487 |

9 | Ø90 | 2.90 | 345 |

10 | Ø100 | 4.00 | 250 |

11 | Ø110 | 5.30 | 188 |

12 | Ø120 | 6.80 | 147 |

13 | Ø125 | 7.75 | 129 |

14 | Ø130 | 8.74 | 114 |

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | 8000 | P+C |

Medium Chromium | ≥50 | 8000 | P+C |

High Chromium | ≥56 | 8000 | M+C |

Model | Chemical Composition | |||||

C | Si | Mn | Cr | P | S | |

Low Chromium | 2.3-3.4 | ≤1.5 | 0.5-1.5 | 1.0-2.0 | ≤0.1 | ≤0.1 |

Medium Chromium | 2.2-2.8 | 0.5-1.0 | 0.5-0.8 | 10.0-12.0 | ≤0.1 | ≤0.1 |

High Chromium | 2.4-3.2 | 0.5-0.8 | 0.5-0.8 | 16.0-18.0 | ≤0.1 | ≤0.1 |

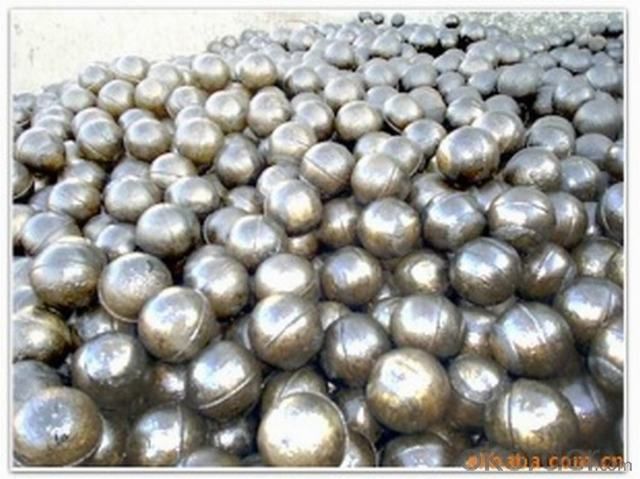

3.Specification of High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

Size: 20mm-150mm

Hardness:HRC58-65; Chrome content:11-14%

4. Photos of High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q: Why do casting parts have air holes?

- There are many reasons for casting porosity, mainly due to:1. smelting process is unreasonable, metal liquid absorbs more gas;2. the gas in the mold invades the metal liquid;3. from the mold is more water brush, core dry;4. the casting has poor ventilation;5. ladle tools are not dry.Wait。

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

- Q: Is 316 casting better than 304 casting?

- The degree of difficulty in the process of casting depends mainly on the structure, precision requirements, and hardness of the casting.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1983 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia, South Asia, Central America, Western Europe, Eastern Asia, Mid East, Oceania, Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English;Chinese;Japanese;Korean |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Grinding steel balls;Grinding steel cylpebs;Grinding media;Grinding meida ball |

| Product Price Range | Average |

Send your message to us

High Chromium Gringding Ball With High Hardness and Resistance, Top Quality For Cement and Mine

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords