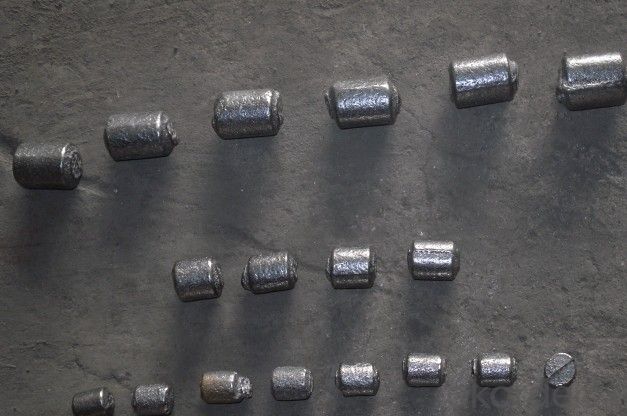

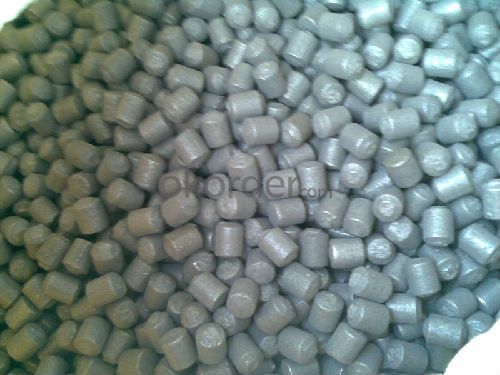

High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant

and Mine:

1:Wear-resistant,No breaking, Good hardness

2:Certification: ISO9001

3:10X15mm-45X60mm

4:Hardness: HRC45-65

5:Cr: 0.8-22%

Feature of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and

Mine:

Even Hardness,

No breakage,

Good wear resistance,

High impact value.

Applied Field of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant

and Mine:

1) Cement Plants, Mines,

2) Power stations,

3) Chemical Industries,

4) Grinding mill.

Chemical Composition of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement

Plant and Mine:

Type | Hardness | Chemical Elements | |||||||

C | Si | Mn | Cr | Mo | Cu | S | P | ||

Low Cr Grinding Cylpebs | ≥HRC45 | 2.6-3.5 | 0.2-1.5 | 0.3-1.5 | 0.8-1.8 | Minim | Minim | ≤0.15 | ≤0.15 |

Middle Cr Grinding Cylpebs | ≥HRC52 | 2.3-3.3 | 0.2-1.5 | 0.5-2.2 | 2.5-8.5 | Minim | Minim | ≤0.12 | ≤0.12 |

High Cr Grinding Cylpebs | |||||||||

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- There are several casesThe first hole with a diameter of less than 4MM is generally not done, or as a hole location only for a period of less than 10MM.Second for the big hole, some of the reasons for the holding force, we must increase the slope, direct tapping is unlikely, so it still needs post-processingThird for products with high tightness requirements, some cores need to be made even if they are very small, so they can be tapped directlyFourth, some due to technical requirements, regardless of the size of each other's requirements must be made, there is no wayThe above methods are common, and they will encounter many small problems in actual production.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- Yes, the cast aluminium is polarized and gray, but the key problem is to guarantee the quality of the aluminium casting, and the quality of the other aluminium casting is not good.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- According to the industry standards, within the scope of the standard requirements to determine whether the product is qualified

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- The tolerance of a specific size can be obtained from the tolerance grade and nominal size of the casting.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

- Q: ZGMn13 casting parts processing, with what knife head good?

- The ZGMn13 itself is not have processing, if only the processing point, sharpening, ordinary can, if the processing area is relatively large, ZGMn13 external impact load is bigger,

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches