High Alumina High Strength Refractory Clay Brick for Wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Strength Fefractory Clay Brick for Wholesale

Specifications

high strength refractory brick

novelty, cheap, unique, fine art, high quality, exquisite workmanship, unique design

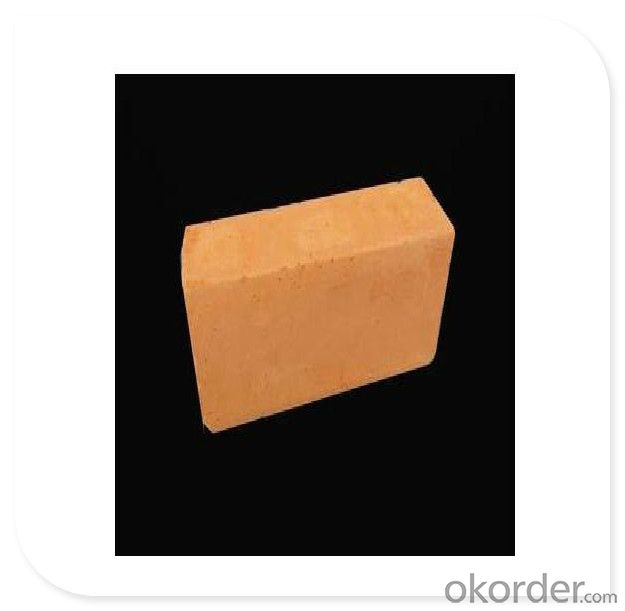

| Productname | Squeezed vacuum brick |

| Size/rectangle |

200*100*(30,40,50) 230*115*(30,40,50) 200*100*(20,25) 230*115*(20,25) 240*120*(20,25) |

| Quality | Grade A |

| Application | Park, Square, Villas, Residential area, The sidewalk ,ect. |

| Packing | 2 tons / tray |

| Features | Wear-resistant,acid-resistant,alkali-resistant,Non-slip, heat-insulation, sturdy |

| Advantage | Environmentally friendly bricks The most competitive price Easy to be constructed The prompt delivery time Excellent after services |

Production & Quality

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packing shipment

2.Quality Control

a.According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

F&A

Q1.Are you a manufacture or trader?

A:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3. Do you provide samples?

Yes, samples are available.

Q4. Do you accept OEM?

Yes, we can do OEM.

Q5.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q6.What are the payment terms?

Usually T/T,but L/C,Western Union etc are available for us.

Q7. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

Q8.How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q9.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q10.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q11.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: Density of high alumina bricks

- The density of high alumina bricks is determined according to the price. The average density is between 2.3-2.5g/cm3. The higher the density, the higher the price, the higher the aluminum bricks are in the industry. More than 2.4 are required.

- Q: The difference between aluminium refractory and magnesia refractory

- Magnesia refractory belongs to alkaline refractory materials refers to refractory products such as magnesia magnesia brick magnesium iron spinel magnesium aluminum spinel magnesia ramming materials and other products of raw materials is the main crystal phase is periclase magnesia products

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Sulphide. A total of more than 200~300 kinds, followed by the type of silicate minerals, the weight of 0.25% of the crust. Chang Fu is an important nonferrous metal deposit, which is an important source of copper, lead, zinc, antimony and so on. It is of great economic value. The main features are: metal luster, color, streak is deep, low hardness, good thermal conductivity, than the major. Another feature is that because sulfides are often associated with magma, it is very easy to oxidize under the surface supergene action. Except for pyrite (6 ~ 6.5 hardness), the hardness is very low. Such minerals pyrite, chalcopyrite, galena, FeS2 CuFeS2, PbS, Sb2S3, stibnite sphalerite molybdenite, cinnabar HgS MoS2.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- If the range of softening temperature exceeds the load, the constants of other physical and chemical indexes will also increase or decrease.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Fire clay -- usually refers to folk point stove furnace set with a kind of soil, limit under atmospheric pressure of 1500 degrees fire clay soil 1, properties and uses: clay brick of weak acid refractory material, its thermal stability is good, suitable for hot blast furnace, boiler and flue, smoke chamber lining, etc..2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

High Alumina High Strength Refractory Clay Brick for Wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords