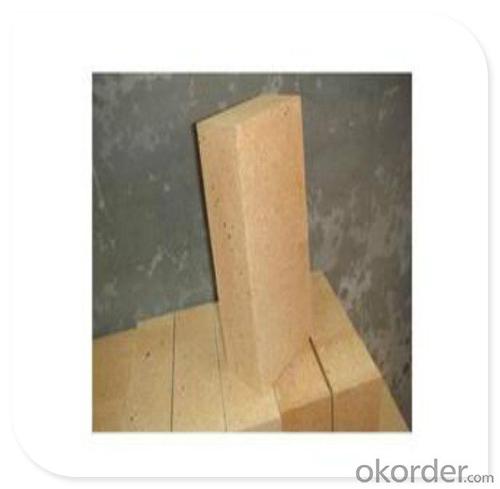

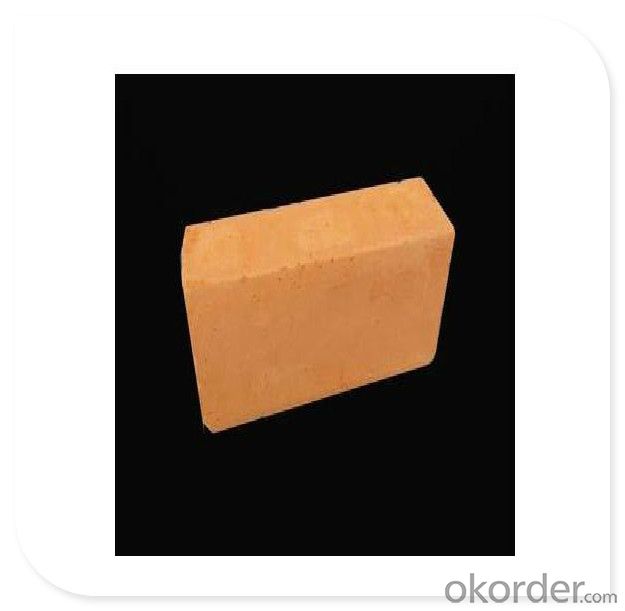

High Alumina Fire Clay Refractory Brick with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fire Clay Refractory Brick with Good Quality

Specification:

fire clay refractory brick manufacturer in Fujian, Chinia.

Thin Clay Bricks for Wall Cladding:

1.W/A:2%-3%

2.Size:240x60x11mm

3.Usage:exterior wall tiles

4.FREE SAMPLES

Material | refractory clay hotsale brick |

| usage | Indoor&ourdoor wall, decoration, building stone material,floor,countertop. |

Size | 6*15cm |

| color | red,yellow,brown,purple,etc |

| package | Strong wooden crates or pallet. |

| Delivery time | Generally within 2-3 weeks after received advanced deposit . |

| payment | T/T(30%deposit of total amount, and then balance before shippment) |

| price term | Based on FOB,CNF |

| business scope | Slabs, Tiles, Skirting, wall stone,Window sills, Steps & Riser stairs, Kitchen countertops, Columns, Curbstones, Paving stones, Cubes, Mosaic & Borders, Sculptures, Tombstones and Monuments |

| client | France, Italy, Portugal, Roman, America, Australia, Middle East and so on |

Production & Quality

1.Production Process

Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packing shipment

2.Quality Control

a.According to the chemical content,raw materials are classified into different levels to ensure quality of brick first.

b.During the production,every brick will be weighed twice strictly to reduce the error of weight .

c.Before delivery, the inspectors will inspect the size,appearance,physical and chemical properties of brick again in factory.

F&A

Q1.Are you a manufacture or trader?

A:To be honest we are a trader,but we have stable cooperation factories.And we can supply good pre-sale service, after-sales service.

Q2.Can we visit your company?

A:Sure,welcome at any time,seeing is believing.

Q3. Do you provide samples?

Yes, samples are available.

Q4. Do you accept OEM?

Yes, we can do OEM.

Q5.What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q6.What are the payment terms?

Usually T/T,but L/C,Western Union etc are available for us.

Q7. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

Q8.How are your products’ quality?

The products will be strictly inspected before shipment, so the quality could be guaranteed.

Q9.How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q10.What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q11.How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: Introduction of high alumina brick

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. If the content of Al2O3 is higher than 90%, it is called corundum brick. Because of the different resources, the standards of different countries are not identical. For example, European countries limit the content of Al2O3 to high alumina refractories by 42%. In China, the content of Al2O3 in high alumina brick is usually divided into three parts: I, etc. - Al2O3 content, >75%, II, etc. - Al2O3 content is 60 ~ 75%, and the content of Al2O3 is 48 ~ 60%.

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The question is good, these two belong to the high aluminum brick products, when many manufacturers buy, I do not know how to distinguish.

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: What is spalling resistant high alumina brick?

- Using bauxite as main raw materials, the introduction of a small amount of ZrO2 (ZrO2 is due to phase transition, between monoclinic and tetragonal type can improve the thermal stability of the products), adding a certain amount of binder and additives, the particle size distribution control mud, forming and sintering of refractory products produced, called anti stripping high alumina brick.

- Q: Use of high alumina refractory bricks?

- Because of the high Al2O3 high aluminum products, low impurity content, the formation of fusible vitreous body less so than the clay brick high load softening temperature, but because mullite crystallization has not formed the network organization, so the load softening temperature is not high silica brick.

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Fire Clay Refractory Brick with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords