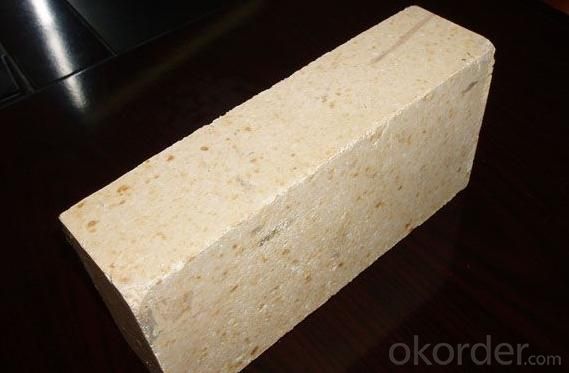

High Alumina Casting Steel Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Specifications

1. AL2O3 : 40%-75%.

2. Can according to customers' requirements.

3. Used for Steel industry casting steel.

Specifications

1. AL2O3 : 40%-75%.

2. Can according to customers' requirements.

3. Used for Steel industry casting steel.

Casting steel refractory brick,Refractory brick for Casting steel,Casting steel brick

Features and advantages:

1. High refractoriness.

2. Good spalling resistance and wear resistance.

3. Good corrosion resistance.

4. Good thermal shock resistance.

5. High mechanical strength.

6. High-temperature creep rate is low.

7. Good volume stability at high temperature.

Physical and chemical indicators:

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- The chemical pH value of high alumina refractory brick belongs to neutral and alkaline refractory brick, and clay refractory brick belongs to neutral and acid refractory brick.

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- The brick Pei boring and time. 6, Pei brick kiln installed between the brick and the brick Pei order, Pei and kiln top, kiln wall gap etc.. 7, high alumina brick kiln plan, and the lack of edges and corners of the scene should be avoided.

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

- Q: Are there any differences between insulating bricks and refractory bricks?

- The refractoriness of insulating bricks is generally below 1400 tons, while the refractoriness of refractory bricks is above 1400 degrees. 3. density insulation bricks are generally lightweight insulation materials, the density is generally in 0.8-1.0g/cm3, and the density of refractory bricks are basically above 2.0g/cm3.

- Q: How are the grades of high alumina bricks differentiated?

- In China, the content of Al2O3 in high alumina brick is usually divided into three categories: I, etc. - Al2O3 content > 75%; II, etc. - Al2O3 content is 60 to 75%; III and so on - Al2O3 content is 48 ~ 60%.

- Q: What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

- Q: How can the refractory brick blast furnace be pulverized and pulverized enough not to be taken away by the wind?

- The gas will directly lead the dome combustion, in order to ensure good mixing, complete combustion of gas and air in a short time, the combustion capacity of short flame or flameless combustion burner, commonly used for semi jet short flame burner.

Send your message to us

High Alumina Casting Steel Refractory Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords