High Alumina Bricks for Industrial Kilns - High Alumina Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

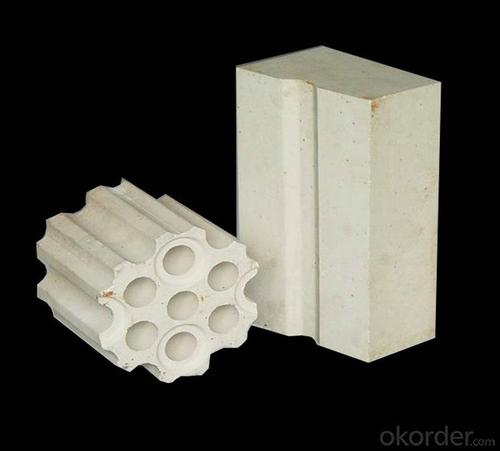

High Alumina Bricks for industrial Kilns

Composite of High Alumina Bricks for industrial Kilns

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks for industrial Kilns

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Acid and alkali resistant

High tensile strength

Resilient to thermal shock

Corrosion resistance

Moisture-proof

Lightweight

Asbestos-free

Wear and erosion resistant

Low creep rate

Application of High Alumina Bricks for industrial Kilns

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

High Alumina Bricks for industrial Kilns Images

Specification of High Alumina Bricks for industrial Kilns

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks for industrial Kilns

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

- Q: What is the heat preservation material used in a laboratory furnace?

- Silicon carbide (SiC) is made from quartz sand, petroleum coke (or coal tar), sawdust (green salt produced when adding green silicon carbide) and other raw materials by smelting with resistance furnace at high temperature. Silicon carbide also rare minerals in nature, Mo sangshi. Silicon carbide, also known as carbon silica. Silicon carbide is the most widely used and the most economical kind of refractory materials in C, N, B and other non oxide refractory materials. It can be called "carborundum sand" or "refractory sand".

- Q: How much is one ton of high alumina refractory brick?

- High alumina refractory brick according to the different content of AL2O3 is divided into grade, grade one and grade two, and grade three high aluminum brick, Zhengzhou Kang Hui refractories factory price in 800-1900 yuan / ton, stable quality, are exported to the domestic and foreign markets.

- Q: What refractory material does cupola lining use?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: How are the high alumina bricks fired?

- Light and high alumina bricks are usually fired in a weak oxidizing atmosphere. In light and high alumina bricks firing, they are often rich in impurities such as R2O, RO, Fe2O3 and so on. They react with Al2O3 and SiO2 at high temperature to produce liquid phase. In the Al2O3 - SiO2 - R2O system, the growth rate of liquid phase increases with the increase of temperature at high temperature. So, because the increase of sintering temperature brings a lot of liquid phase, the decrease of liquid viscosity will lead to the deformation of brick and the decline of brick high temperature function. Therefore, the lower sintering temperature and longer holding time should be adopted in the sintering process dominated by liquid phase sintering. The production practice shows that the same firing temperature can be used for the high grade aluminum bricks. When fired in an inverted flame kiln, it is usually 1430 degrees centigrade and insulated by 40H. The high alumina bricks such as Ill are 1390~1420 degrees centigrade. When the tunnel kiln is fired, they are 1550 and 1450~1500 degrees centigrade respectively. High alumina brick is usually made of weak oxidizing atmosphere.

- Q: Can high alumina brick resist carburizing?

- Louzhu can use heavy impervious material, it is neither high alumina brick nor mullite, this product can resist seepage and have good compressive strength

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Refractoriness is the property of a refractory against high temperature, which means the temperature at which a refractory is softened to some extent after heating, but not its melting point. According to the degree of refractory, refractory materials can be divided into: General refractories, refractory degree is 1580 to 1770 DEG C; advanced refractories, refractory degree is 1770 to 2000 DEG C; special refractory material, refractory degree is greater than 2000 DEG C.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

Send your message to us

High Alumina Bricks for Industrial Kilns - High Alumina Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches