High Alumina Bricks for Industrial Furnace - High Alumina Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description for High Alumina Refractory Bricks for Industrial Furnace

CMAX high alumina bricks are classified according to alumina content ranging from 48% to 90%.

CMAX high alumina bricks are commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc.

Brief features for high alumina bricks

Low thermal conductivity

Excellent acid and base slagging resistance

High refractoriness

Excellent thermal shock resistance

Excellent mechanical strength

Good spalling resistance and wear resistance.

Good corrosion resistance.

High-temperature creep rate is quite low.

Good volume stability at high temperature.

Low bulk density, low thermal conductivity, good thermal insulation performance.

Technical data for high alumina bricks

| ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 |

| Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 |

| Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 |

| C.C.S. Mpa | 39 | 44 | 49 | 53 | 55 |

| Refractories Under Load (0.6)℃ | 1420 | 1470 | 1500 | 1520 | 1500 |

| Reheating Linear Change (%) 1550℃×2h | 0.1 ~-0.4 | 0.1 ~-0.4 | 0.1 ~-0.4 | 0.1 ~-0.4 | -0.5~+0.5 |

| Chemical Composition (%)Al2O3 | 48 | 55 | 65 | 75 | 80 |

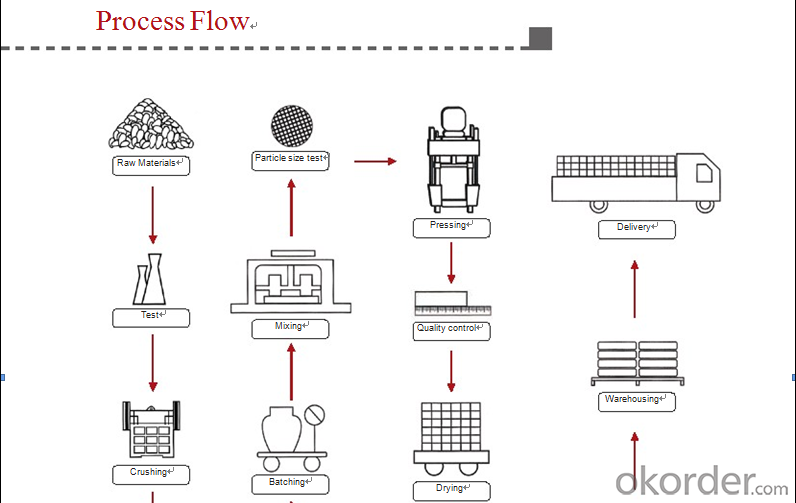

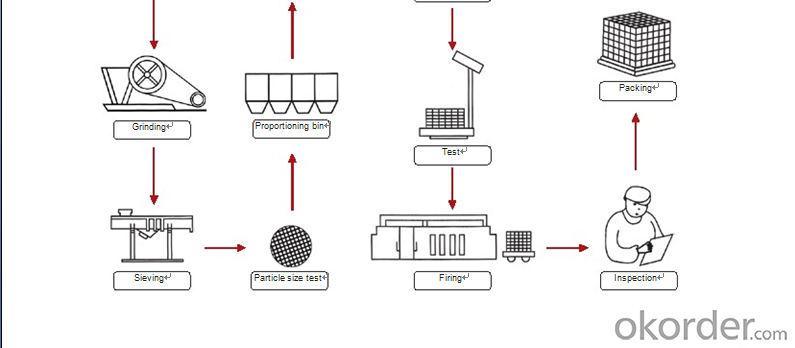

Images/photographs for high alumina bricks

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: Application characteristics of high alumina brick

- Slag resistance. Due to the high alumina brick products in the three oxidation of two aluminum is neutral and high content, so this material products for acid-base slag corrosion resistance.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: Can high alumina brick resist carburizing?

- The key is to look at the content of Fe3O2 metal oxides (so-called anti carburizing brick generally refers to the content of Fe3O2 less than 1% clay brick and Gao Lvzhuan) just a photo shoot, out for everyone to see, high alumina brick common in reductive atmosphere has been chalking up.

- Q: What are the characteristics of high alumina bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: What are the lining structures of lime rotary kilns and what are the requirements for refractories?

- The current configuration of domestic calcining active lime rotary kiln refractories are as follows: the discharge end of low cement high alumina castable with 3% steel fiber; the cooling zone and the firing zone: dry magnesia spinel brick with high aluminum brick with high temperature; preheating: high alumina brick; low temperature preheating zone: clay brick light clay brick; feeding end: low cement high alumina castable with 3% steel fiber; in addition, brick size also have the corresponding requirements; dimensional tolerances: dimensional tolerances used in different parts of the requirements are not the same, the general control in 2mm; corner damage: general permit edge damage 40mm and 5mm deep within angle loss in the hot and cold surface is allowed to have only one, three edges and the length of not more than 50mm; there are cracks parallel to the use of surface crack is not allowed, cracks of brick surface are allowed.

Send your message to us

High Alumina Bricks for Industrial Furnace - High Alumina Refractory Bricks

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 1500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords