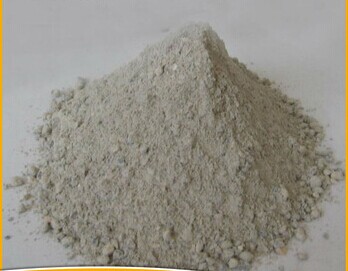

High Alumina Brick Fire Clay High Alumina Cement

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.high alumina cement.

2.Easy to use.

3.High refractoriness.

4.Factory outlets

Introduction:

High strength high alumina castable is made of super high alumina clinker, composite binders and adhesives. The products are featured with high strength, good wear resistance, permeability resistance, erosion resistance, good mechanical properties, convenient construction, etc. It is commonly used in top of CFB boiler furnace, rear wall, etc.

Characters of refractory castable:

1. High refractoriness, high refractoriness under load.

2. High density, low porosity.

3. Good slag resistance and corrosion resistance.

4. High strength and wear resistance.

5. Good resistance to flake performance.

6. Good thermal shock stability.

7. Scouring resistance

8. Good hot strength.

- Q: What is fireproof concrete?

- A series of concrete with fire resistance and heat resistance is made of Portland cement series as cementing material and heat-resistant material as aggregate. Silicate fireproof heat-resistant concrete with Portland slag cement, Portland cement and water glass as cementing material, broken clay brick, clay, cement clinker, broken high alumina brick as aggregate.

- Q: What refractory material does cupola lining use?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: Corundum, high alumina and fireclay refractory difference is what

- In fact, they are not consistent with raw materials, corundum refractories can use white corundum, white corundum, brown corundum corundum material, alumina content of these materials is higher than 90%, while the high aluminum refractory material is bauxite, alumina in 90 to less than 70, and clay raw materials the aluminum content is less than 70..

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Fire resistance is an important performance index of refractory materials, but it does not represent the highest temperature in actual use of refractory materials. In actual use, refractories also bear certain pressure, therefore, must consider the high strength at high temperature refractory material, which is in high temperature under certain pressure without deformation, such as the NZ-40 refractory refractory degree up to 1730 DEG C, but the maximum temperature is only 1350 degrees celsius.

- Q: How to distinguish the good or bad of the high aluminum brick?

- Weigh the weight of the next block. According to the weight standard, a high alumina brick is 3.9 kg in weight, two in high alumina brick, three in high aluminium brick and 4.5 kg in 4.2. The same grade, the same type of high alumina brick, if the weight of a single brick to this standard, but for high quality high alumina brick, otherwise, can not reach such a weight, it shows good quality. If there is a crack, a large piece of broken angle, four sides of inequality, it is for substandard products.

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: Use of high alumina refractory bricks?

- High alumina brick refractory than clay refractory bricks and brick refractory degree are higher, up to 1750~1790 DEG C, which belongs to high-grade refractory materials.

Send your message to us

High Alumina Brick Fire Clay High Alumina Cement

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords