High Alumina Bricks for Kilns - High Alumina Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

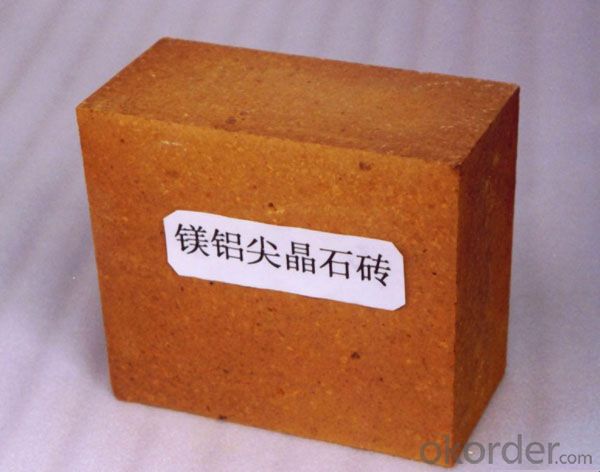

| Place of Origin: | Shandong, China (Mainland) | Shape: | Block | Material: | Alumina Block |

| SiO2 Content (%): | 15.2% | Al2O3 Content (%): | 72.5% | MgO Content (%): | / |

| CaO Content (%): | 0.3% | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | / |

| SiC Content (%): | / | Model Number: | ISO Shapes | Brand Name: | cnbm |

| Application: | furnaces kilns | Color: | Yellow | Classification: | High Alumina |

| Service Life: | More than 2 years | Refractoriness: | 1770 | Bulk Density: | 2500-2600 kg/m3 |

| Apparent Porosity: | 23% | Cold Crushing Strength: | 60Mpa | 0.2MPa Refrctoriness under load: | 1500 |

| Alkanlines: | 0.4% |

Packaging & Delivery

| Packaging Details: | Packaged on wooden pallet and wrapped with polyethylene shrink wrapping, which provides proper stability and protection for materials during transporting and against bad weather conditions. As an option for added protection, polyester strapping may be applied. The dimensions of the pallet depend on the size of the shapes, and normally may be stacked up to three pallets high at the most. |

| Delivery Detail: | upon to the quantity of order |

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Natural element minerals. Of minerals produced by an element (elementary substance). There are about 90 natural elements in the earth's crust, accounting for 0.1% of the total weight of the earth's crust. Can be divided into metal elements, mainly platinum and copper, silver, gold, etc., non-metallic elements, carbon, sulfur, etc., half metallic elements, arsenic, bismuth and so on.

- Q: How to distinguish the good or bad of the high aluminum brick?

- The general high alumina bricks used in the steel, steelmaking, hot blast furnace, electric furnace, blast furnace, reverberatory furnace, rotary kiln lining of industrial furnace in China, mainly composed of a bauxite; sillimanite minerals (including kyanite, andalusite, sillimanite etc.); synthetic material, such as alumina synthesis of mullite, corundum, etc.. High aluminum brick has good quality, high refractoriness, long life and other characteristics, is the main use of refractory brick kiln products, commonly used units can not distinguish the quality and grade of high aluminum brick right in the procurement time, caused by the high prices to buy low grade products, thereby reducing the furnace life therefore, Zhengzhou's Sindh yuan refractory material factory in here is simple to introduce how to identify the quality when purchasing brick high alumina brick.Color: in the purchase of high alumina brick, first of all to see the color, high quality aluminum brick surface smooth, yellow color white, four sides smooth, no broken angle, no cracksWeight: the weight of a block of bricks to be called, according to the standard weight level, high aluminum brick weight of 4.5 kg. Two grade high alumina brick weighs 4.2 kg, three high aluminum brick weighs 3.9 kg, the same level, the same parameters can reach this standard can be regarded as high-quality high aluminum bricks, the opposite is not up to the weight that the quality is good, if there is a crack, four angle uneven, off angle phenomenon, then substandard products, some of the above points to help to the purchaser

- Q: Use of high alumina refractory bricks?

- Because of the high Al2O3 high aluminum products, low impurity content, the formation of fusible vitreous body less so than the clay brick high load softening temperature, but because mullite crystallization has not formed the network organization, so the load softening temperature is not high silica brick.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Bricks for Kilns - High Alumina Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords