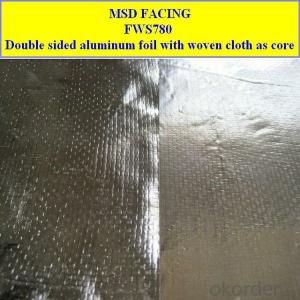

Galvanized Hexagonal Wire Netting for Chicken Fencing with Roofing Insulation Plates

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

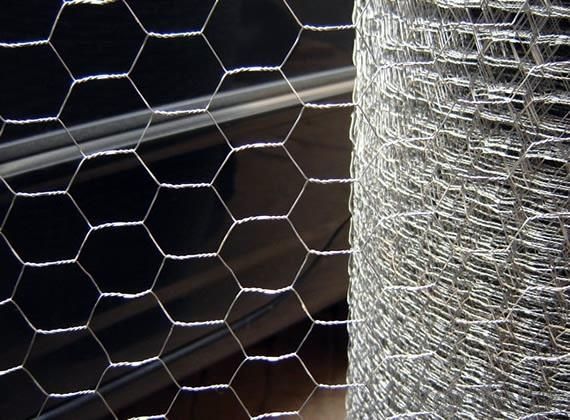

Introduction of 3/4 Inch Galvanized Hexagonal Wire Mesh before weaving for Chicken Fencing

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of 3/4 Inch Galvanized Hexagonal Wire Mesh before weaving for Chicken Fencing

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of 3/4 Inch Galvanized Hexagonal Wire Mesh before weaving for Chicken Fencing

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: As opposed to other roof structures, such as Mansard or Hipped roofs. If so, is it because there is a lesser distance between the internal heat source and the roof?

- Hm. Tough one. Could be. I would think because there is less surface area.

- Q: I have an apartment building that has mold in it. I'm trying to do everything I can to increase the airflow. Sure, the tenants might have to spend a mint on heat, but if it improved the air quality, maybe it would be a good idea.

- mold needs moisture to start/grow. find out why there's moisture and fix that first. Just creating more air flow won't stop the mold from growing and it won't necessarily make the air quality better if mold is growing in the walls. since you said it was roof insulation, (I'm gonna assume you meant attic) check the roof for leaks. I wouldn't think you'd have to get rid of all the insulation but I'd definately get rid of anything moldy. Blown in isulation is fairly cheap to replace. Lowe's sells a mold test kit, not sure how it works but I saw them yesterday when I was in there. Might be worth looking into getting one.

- Q: I live in central florida. I plan on installing R-30 insulation to the floor of my attic. How effective is it to install reflective insulation to the attic on the roof side? Is it worth the price?

- do not insulate your roof,it will cause the roof to get VERY hot,this will damage the roofing,shorten its life,,the temp in your attic should be within 3-4 deg of outside temp,,,insulate the floor Only and have plenty of ventilation

- Q: I am really confused about this science stuff! Sustainability is terrible xP

- All versions of insulation are largely air that is kept from moving - air is a good insulator if convection - movement of heated or cooled air due to changes of density - is prevented. This assumes that a vapor barrier and caulking prevent actual air movement through the wall when a wind is blowing. Some insulators are also poor conductors of heat so the connection between inside and outside that might occur is broken. As it happens, glass used in fiberglass and minerals used in rock wool are actually pretty good conductors of heat in solid form but as fine particles and flakes they don't conduct well from one strand/piece to the next.

- Q: or in queensland

- Depends on whether you are employed or working contract. Currently it could be 18-25 per hr for employee or upto 40 per hr for contract depending on allowances and if you are providing your own vehicle or company vehicle. Then are you doing bats or anticon, it is usually charged on a sqm rate. Call some roofing companies or insulation companies and ask them what their rates are.

- Q: what effect does changing the pitch of a roof have on the insulation properties and durability of a roof?

- The pitch of a roof has zero effect on the r-rating of insulation. Proper ventilation of the attic space, whether steep or low pitched, simply provides the optimum environment for the r-factor of the insulation to do its job more efficiently. Any attic, regardless of pitch, if it is not properly ventilated, would stress the effectiveness of any insulation product unnecessarily. The durability of the roof is not adversely affected either.

- Q: Does snow on the roof help or hurt my heating bill?

- I mostly shows that your home is well insulated and not loosing heat through the ceiling to melt it. Think of an Igloo made of packed snow. It can be kept at a temperature just below freezing so that it will not melt and still keep those inside from the 30-60 below outside.

- Q: I have a valley between two roof peaks that gets a huge icicle every year. I know this area is not insulated very well. In the house it is a dead area between two rooms. I would like to get someone over here and blow it full of insulation (couple calls in, awaiting response). In the meantime, I do have heat tapes installed on the roof in this area. It's a 50' run, zigzagged and some goes into gutter and the downspout.I am paranoid of fire hazards and have a real problem leaving these tapes plugged in. That being said, I realize snow is all around and water is flowing in this case. Is it safe to leave these plugged in?Is there a time I should be unplugging?Will this help my icicle problem?Serious replies only please. I prefer from a licensed contractor/insulator.Thanks in advance.

- I have never experienced a problem with heat tape. as long as it is in good shape and you have it plugged into a GFI, I personally wouldn't worry about it to much at all. your roof gets hotter in the summer with the sun beating on it then the heat tape can create. so it starting a fire would be unlikely. the lack of insulation in that area is compounding your problem. so get that taking care of if you can. heat tape is melting snow and ice, melting snow and ice makes ice cycles. the heat tape in the gutter will help to keep the gutters clear allowing the water to flow down the spout so in theory it should not create as many ice cycles as without the tape. again the lack of insulation is allowing more snow to melt from heat loss through the roof. hope this helped, good luck

- Q: I gutted the room and now would like to rebuild. One side of the room slants (it's the roof) and the other side of the room is a dormer (all low ceilings).I want to insulate the ceiling but have no ridge vents so no moving air as someone mentioned I should have. I want to install foam channels to keep the insulation away from the roof but not sure if this is a good idea without the ridge vents. I will have a vent to the outside installed on the very top of the roof however and the small attic space is open all the way through the other two upstairs rooms and I will add another roof vent on that end of the house. I will only be able to install 3 inch insulation but that's better than none at all. I live in the northeast and was told if the job isn't done right I can get ice jams in winter. Also I don't see any way to drill ridge vents. would it be ok to just install the styrofoam channels and insulate then sheet rock or am I asking for trouble? Thanks in advance for any help.

- Suggestion: install the insulation with the foam channels but leave the center section (roof ridge area) open from end to end. At each end you can install a static vent or an active one. Depending on the amount of space you have you may be able to install a power vent.If you can send me a diagram with measurements I can give you a more definitive answer.

- Q: I've found lots of building forums and general "building advice" columns that go over very high-level pros/cons to choosing roofing material and insulation options, but I want a site where I can see hard costs of ordering each of the materials so I don't have to call up a ton of contractors or dealers. Does such a comparison site exist? Everyone offers quotes, but that takes too much time to apply for quotes to every dealer.I'm specifically interested in knowing what green options I can afford (cotton batting vs. formaldehyde-free fiberglass, etc.).

- You could call ABC supply or Norandex Reynolds, they are the biggest distributors I know of. They may have some resources for you.

Send your message to us

Galvanized Hexagonal Wire Netting for Chicken Fencing with Roofing Insulation Plates

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords