Heavy Duty Aluminum Baking Sheets with Different Colors and Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coil with Different Colors and Applications Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil with Different Colors and Applications:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

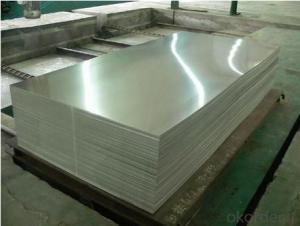

Images of the Aluminium Coil with Different Colors and Applications:

Aluminium Coil with Different Colors and Applications Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: The which temperature the aluminum evaporates in vacuum?

- Aluminum boils at 2519 °C (4566 °F) at normal pressure. In a vacuum, it might boil (a little) at 808 °C, but actually this is better known as subliming.

- Q: Can aluminum sheets be used for modular construction?

- Absolutely, modular construction can utilize aluminum sheets. Aluminum proves to be an adaptable and lightweight substance that presents numerous advantages for modular construction undertakings. Its resilience, resistance to corrosion, and impressive strength-to-weight ratio render it appropriate for a wide range of structural applications. The malleability of aluminum sheets permits them to be effortlessly fabricated and molded into various forms and dimensions, enabling flexibility in both design and construction. Furthermore, aluminum's recyclability positions it as an environmentally conscious selection for sustainable construction practices. All things considered, aluminum sheets stand as a feasible choice for modular construction given their robustness, durability, and versatility.

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent surface marring of aluminum sheets during handling, it is important to take proper precautions such as wearing gloves to avoid direct contact with the metal. Using protective padding or blankets when stacking or moving the sheets can also prevent scratching or denting. Additionally, using specialized lifting equipment or handling tools that distribute the weight evenly can minimize the risk of surface marring.

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- Architectural aluminum sheets come with a variety of surface treatments that serve to improve their appearance, durability, and performance. These treatments make the aluminum suitable for a wide range of architectural applications. One commonly used surface treatment is anodizing. This process entails immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on its surface. This oxide layer can be dyed to achieve the desired color or left clear to maintain a natural metallic appearance. Anodized aluminum sheets are highly regarded for their excellent resistance to corrosion, scratches, and color fading. Another surface treatment option is powder coating. In this method, a dry powder is electrostatically applied to the aluminum sheet and then cured in an oven. The powder melts and fuses to the surface, resulting in a smooth and durable finish. Powder coating offers exceptional color retention, weather resistance, and resistance to chipping and cracking. A third type of surface treatment is PVDF coating, which involves applying a high-performance fluoropolymer resin called polyvinylidene fluoride to the aluminum sheet through a coil coating process. PVDF coatings are known for their exceptional resistance to fading, chalking, and chemical attack, making them perfect for exterior applications where color retention and durability are crucial. Additionally, there are various mechanical surface treatments available for architectural aluminum sheets. These treatments, such as brushing or polishing, can be employed to achieve the desired texture or reflectivity on the surface. Mechanical treatments allow for the creation of brushed, satin, or mirror-like finishes, adding aesthetic appeal to the aluminum sheet. To summarize, architectural aluminum sheets can be treated using anodizing, powder coating, PVDF coating, or mechanical treatments. Each treatment offers unique advantages and characteristics, enabling architects and designers to select the most suitable option for their specific project requirements.

- Q: What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets is around 70 GPa (Gigapascals).

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- There are two methods: 1 AB glue or epoxy resin adhesive. 2. If the thickness of the two plate is greater than 8MM, it can be fixed by flat screw. Hope to be available.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: What will reflect light more- aluminum foil or white paper?

- Indestructible okorder /

- Q: What's the price of the 6mm aluminum sheet?

- Aluminum single board, white meters, Beijing reference price of 320 yuan / square meter, specific to take into account your size, material requirements, plate type and so on, generally see drawings quote.

Send your message to us

Heavy Duty Aluminum Baking Sheets with Different Colors and Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords