Heavy disc feeder machine, heavy apron vibrating feeder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

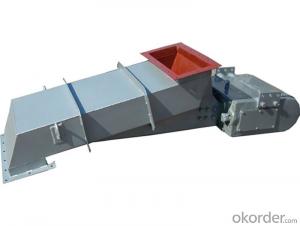

Heavy disc feeder machine, heavy apron vibrating feeder

Introduction Overview of Heavy disc feeder machine, heavy apron vibrating feeder:

WZMBR, MBR heavy disc feeder is a feeding device of volume measurement, WZMBR, MBR heavy disc feeder is seat mounted, the transmission structure is sealed and can work in environment with much dust. It has large capacity and usually installed directly in the lower part of storage bin to feeding other devices.

Application of Heavy disc feeder machine, heavy apron vibrating feeder:

Widely used in metallurgy, chemical industry, coal, building materials and electric power and other industries.

Advantages of Heavy disc feeder machine, heavy apron vibrating feeder:

1.Use special heavy disc, high carrying capacity, more than 10 years service life.

2.Equipped with a frequency conversion motor, stepless adjust feeding amount.

3.Wet type disc feeder can be applied to materials with corrosive occasions.

4.The equipment with compact structure and small occupied space.

5.The transmission mechanism is reliable, maintenance is simple, and the maintenance period is long.

6.Transmission efficiency is as high as 90%.

7.Provided with a wear-resistant lining board, the service life is prolonged, and less maintenance.

8, connected to the silo outlet is large in size, easy to install and nesting materials.

9.Use advanced frequency conversion motor for power, easy to adjust the amount of feeding steplessly.

Technical parameter table of Heavy disc feeder machine, heavy apron vibrating feeder:

Model | Granularity | Bulk density | Water content | Diameter of disk | Production capacity | Rotational speed of disk | Variable frequency motor power |

mm | (t/m3) | (%) | mm | m³/h | r/min | kw | |

WZMBR800 | 40 | 0.5-2.5 | Usually≤8%

Rainy season≤12%

| 800 | 1.8-9 | 1.6-8 | 7.5 |

WZMBR1000 | 50 | 1000 | 3.4-17 | 7.5 | |||

WZMBR1200 | 80 | 1200 | 7-34 | 1.2-6 | 11 | ||

WZMBR1600 | 90 | 1600 | 14-70 | 15 | |||

WZMBR2000 | 125 | 2000 | 21-105 | 22 | |||

WZMBR2500 | 150 | 2500 | 40-210 | 30 |

- Q: The opening process of press filter from feeding to discharging is described briefly

- Close all piping valves and continue to remove extrusion pressure.After opening the filter, the filter press is opened and the cake discharge is carried out.

- Q: What's the simplest ore radio to do?

- The most simple ore radio, a three meters above the overhead antenna, a ground wire, a 2AP9 diode, a high impedance diode in parallel with the headset, headset received two world online, only listen to the strongest local Taiwan, if there is more than a strong one mix together.

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- The feed enters the crushing chamber from the top of the rotor, the rotor can be reversed and used, and the hammer can be replaced less than two times. The feed is mainly suitable for processing fine fodder.

- Q: How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size of the feed port of the crushing equipment and the size of the feed size, whether it matches the material, such as whether the material can enter the machine and produce it smoothly

Send your message to us

Heavy disc feeder machine, heavy apron vibrating feeder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches