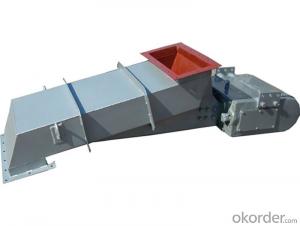

Good Quality Vibrating Feeder Equipment For Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Vibrating feeder is generally installed in front of the primary crusher, conveys big blocks continuously and evenly while removing the dirt and impurities by screen bars. As a necessary equipment, it can effectively control the feeding capacity to match with the capacity of the whole crushing plant. It features strong construction, anti-strike and wearable.

Features of vibrating feeder:

1) Vibrating feeder enjoys simple structure, stable vibrating, even feeding, good continuous performance, adjustable excitation force, etc. Its flow rate can be conveniently changed and controlled.

2)Vibrating feeder adopts eccentric block as the excitation source and features low noise, low energy consumption, good adjusting performance, and no material splashing.

3)Closed type vibrating feeder can prevent the pollution of dust.

4)The pressure caused by the material to the groove should be reduced to the greatest extend. The effective discharge opening should be smaller than the one quarter of the groove width. The flow rate should be controlled within 6-18m/min.

5)For feeding materials with a large quantity, a fender with enough height should be installed at the outlet. This fender should not be fixed to the feeder since it will affect the performance of the machine.

Application of vibrating Feeder :

Vibrating feeder can feed lump or granulated materials to the other devices evenly and continuously. In sand and gravel production line, the continuous feeding of the vibrating feeding machine helps avoid the blockage at receiving hopper. With easy flow adjustment, low noise and energy consumption, vibrating feeder is applied to crushing and screening production lines on crushing site, in mining, metallurgy, building material, chemistry, mineral processing, and coal industries.

Technical Parameters:

| Model | Max. Feed Edge (mm) | Processing Capacity (t/h) | Eccentric Shaft Speed (r/min) | Motor Power (kw) | Number of Motor | Overall Dimensions (L*W*H) (mm) | Weight (t) | Chute Size (mm) |

| GZD-300*90 | 425 | 40-100 | 2*2.2 | 2 | 3307*1430*1450 | 2.55 | 900*3000 | |

| GZD-380*96 | 550 | 80-150 | 2*(3-3.7) | 2 | 3870*1860*1190 | 3.24 | 960*3800 | |

| 2GZD-380*96 | 550 | 80-160 | 2*5.5 | 2 | 3870*1500*1200 | 3.8 | 960*3800 | |

| GZZ-490*110 | 630 | 150-250 | 500-800 | 18.5 | 1 | 4900*1660*1420 | 5 | 1100*4800 |

| GZZ-600*120 | 750 | 190-280 | 500-900 | 22 | 1 | 5950*1760*1420 | 6.6 | 1200*5800 |

| ZSW-380*96 | 550 | 80-150 | 500-720 | 11 | 1 | 3882*1700*1350 | 4.36 | 960*3800 |

| ZSW-490*110 | 630 | 120-280 | 500-800 | 15 | 1 | 4957*1850*1350 | 5.3 | 1100*4900 |

| ZSW-590*110 | 700 | 200-350 | 500-800 | 22 | 1 | 6000*1840*1400 | 6.3 | 1100*5900 |

| ZSW-600*130 | 750 | 400-560 | 500-800 | 22 | 1 | 6082*2000*1450 | 7.8 | 1300*6000 |

- Q: The opening process of press filter from feeding to discharging is described briefly

- Open the central blowback return valve, send compressed air, and clean the inlet channel. The time is set according to the experience and the setting time.

- Q: What's the simplest ore radio to do?

- The most simple ore radio, a three meters above the overhead antenna, a ground wire, a 2AP9 diode, a high impedance diode in parallel with the headset, headset received two world online, only listen to the strongest local Taiwan, if there is more than a strong one mix together.

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- Axial feed from the main shaft into the crushing chamber, suitable for crushing grain, but after feeding the entrance to install slices, but also crushing grass, stems and so on.

- Q: How to choose crushing equipment suitable for its own ore material?

- To see the hardness and brittleness of the ore material itself, if these can not clear the direct contact of crushing equipment manufacturers, they are generally more clear, can choose the required type of crushing equipment according to the characteristics of the material itself, such as hard material cracking, general hardness can be used to hammer breaking etc.

Send your message to us

Good Quality Vibrating Feeder Equipment For Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches