Best design of ZZF vibrating feeder with high efficiency

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

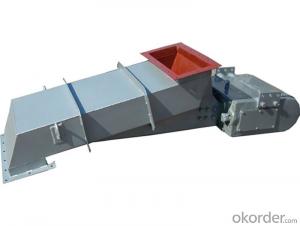

Best design of ZZF vibrating feeder with high efficiency

Introduction Overview of ZZF vibrating feeder from Winner:

ZZF vibration feeder is composed of motor, tank, transmission shaft, exciter, leg and damping spring, the feeding process is driven by the vibrator driving groove in the mine with two motors, along the inclined direction do linear reciprocating cycle to achieve feeding, eventually the material continuously and uniformly sent to the receiving opening. Is the necessary equipment to implement automated assembly line.

Application of ZZF vibrating feeder from Winner:

ZZF vibrating feeder is widely used in the following industries: metallurgy, mineral processing, coal and other industries.

Advantages of ZZF vibrating feeder from Winner:

1.Small size, light weight, simple and compact structure;

2.Installation and maintenance is convenient, operation cost is low;

3.Large feeding capacity;

4.Low noise, is beneficial to improving the working environment;

5.Energy saving: low power consumption, high power factor;

6.Stable amplitude, reliable operation, strong adaptability to various materials;

7.ZZF series vibrating feeder can achieve automatic, timing and quantitative ore-drawing;

Technical parameter table of ZZF vibrating feeder from Winner:

Model | Feeding granularity | Angle | Capacity | Motor | Power | Vibration frequency | Double amplitude | Remarks |

mm | º | t/h | Kw | Hz | mm | |||

ZZF-1000 | 0-300 | 18 | 1000 | Y132M2-6 | 2x5.5 | 16.6 | 6-8 | Without secondary vibration reduction |

ZZF-1500 | 0-300 | 20 | 1500 | Y160M-6 | 2x7.5 | 16.6 | 6-8 | |

ZZF-2000 | 0-300 | 20 | 2000 | Y160L-6 | 2x11 | 16.6 | 6-8 | |

ZZF-2500 | 0-500 | 20 | 2500 | Y180L-6 | 2x15 | 16.6 | 6-8 | |

ZZF-3000 | 0-500 | 20 | 3000 | Y225S-8 | 2x18.5 | 12.5 | 6-8 | With secondary vibration reduction |

ZZF-3500 | 0-500 | 20 | 3500 | Y225M-8 | 2x22 | 12.5 | 8-11 | |

ZZF-4000 | 0-800 | 20 | 4000 | Y225M-8 | 2x22 | 12.5 | 8-11 | |

ZZF-5000 | 0-1000 | 23 | 5000 | Y280S-8 | 2x37 | 12.5 | 8-11 |

- Q: What is the standard value of GRC durability?

- The durability of the GRC standard value is actually not a strict labeling, usually measured in life, in the last century in 90s generally can be used for 20 years, and now can be used for 50 years, a few can be used for 70 years, 70 years it can be said with the same building life.

- Q: What is the difference between GRC wallboard and aerated block wall?

- Because of the composite structure of GRC surface layer and high thermal resistance core material, GRC composite wallboard has high strength, high toughness, high impermeability, high fire resistance and weather resistance, and has good insulation and sound insulation performance.The surface material for producing GRC composite exterior wall panels is the same as other GRC products. The core layer can be matched with cast-in-situ cement expanded perlite mixing material, or prefabricated insulation materials (such as rock wool board, polystyrene foam board, etc.). Generally, the anti - roll forming process is adopted. When the molding is made, the face of the wallboard is contacted with the surface of the template, so the quality of the face of the wallboard is better. The GRC surface of wallboard is usually made by direct injection method. The built-in reinforced concrete ribs are made of welded steel frames and C30 bean stone concrete made from sulphoaluminate cement.

- Q: GRC cement products have cracks, what are the reasons?

- Strengthening the maintenance, reducing the hydration heat of cement and controlling the internal temperature of concrete products are effective measures to reduce the cracks on the surface of cement products.

- Q: How to identify new wall panels

- In accordance with the different materials of new wall panels can be divided into three types: (1) GRC new wall, the main material is decreasing sulfur aluminum acid salt cement, coal ash, ceramsite, perlite, mesh or steel mesh; (2) kneading cement wall, the main material is ordinary cement, coal ash, washed; (3) high strength cement wall, the main material is magnesium chloride and Magnesium Oxide, commonly known as magnesite, alkali mesh.

- Q: GRC jet equipment prices?

- We offer a full set of GRC injection equipment at 16800 yuan

- Q: What are lightweight partitions and lightweight partition materials?

- GRC lightweight partition material glass fiber reinforced concrete; this is a kind of fiber cement composite with alkali resistant glass fiber as reinforcing material and cement mortar as base material. Equipment foundation construction of aerated concrete block. Its outstanding feature is that it has good tensile and flexural strength and good toughness. This material is especially suitable for making decorative shapes and for displaying strong textures. Compared with these exterior wall decoration materials, the biggest advantage of GRC material is that it can meet the individual needs of architects and complete the expression of various decorative shapes and textures.

- Q: What about the air leak in the flue?

- When you want to see what kind of flue air leakage, the division of the usual general exhaust flue or kitchen flue, if the kitchen smoke exhaust, air leakage will be repaired immediately. To make, it is not can replace the exhaust pipe.

- Q: Daming Palace building materials wholesale GRC European style component where?

- To many, I suggest you find well-known high, customized, are generally required to design CAD drawings, people help you do, we have done before the project is in Qinglong

- Q: GRC roofing made waterproof layer, how much is one square metre?

- The "Rainbow" brand PBC-328 non curing rubber asphalt waterproof coating is made of high quality asphalt, functional polymer modifier and special additives scientifically optimize mixture, maintain a viscous paste waterproof material in application state. The product has outstanding creep properties, and comes with outstanding applications such as healing, anti seepage, anti channeling, fatigue, aging and stress free.

- Q: What's the difference between partitions?

- There are many types of partition board, such as partition board raw material is not the same, the product is not the same, such as composite fiber, cement, foam, ceramsite and so on.There are many types of partition board products, such as interior wall panels, exterior wall panels, their length, thickness requirements are not the same.

Send your message to us

Best design of ZZF vibrating feeder with high efficiency

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches