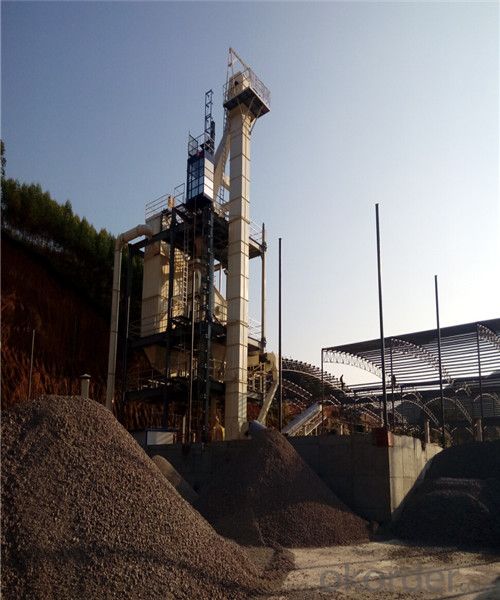

0-4.75mm Dry Sand Making System without any Powder in Site

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dry Method Sand Making System introduction

Dry Method Sand Making System is researched and designed by the senior engineer of CNBM with 10 years experience , it combined all the machine into one equipment, including sand making , separating , dust separation and collection etc for crushing ,grinding ,stone-breaking-stone and reduce the motor power for the main machine .The final products is with stable gradation, cubic shape, adjustable fineness modulus . We control the stone powder content to meet National Standard effectively with Stone-Powder Separation Patent Technology . The final products from our Dry Method Sand Making System meet the requirement for high characteristic concrete and dry-mixed mortar . It saves much cost because the comprehensive performance of the final products is better than river sand and mountain sand . It leave out the heating procedure and save cost with the improved durability and strength and other performance for concrete . The final sand can be used directly without water washing . It is the first choice equipment for sand making in quarry , concrete industry, dry-mixed mortar industry without mixing river sand to adjust the ratio .

Dry Method Sand Making System Advantage :

1. The sand mould is premium.

During production process, “pounding, milling and rock hit rock” are all in one. Finished sands are gradating stability and in good shape (containing 10% or less micro-grading flour). All the sands are almost no flakiness. The finished sands are with more angular, nearly circular, fineness modulus (2.3 ~ 3.0). The percentage of powder content (below 10%) is adjustable. All the performance indicators are meets the national “Architecture Sand” standard GB14684-2011.(patented equipment).

2. Low energy consumption.

The energy consumption is 3kW/t which save 60% energy than the similar international or domestic products, greatly reducing the cost of production. Suit for the concrete sand cause its disposable sand ratio reach 0~4.75mm (>70%). And suit for dry-mixed mortar cause its disposable sand ratio reach 0 ~ 2mm(>40%).

3. Feed size range.

Feeding size from 0mm ~ 120mm.

4. Low noise.

Lower than traditional sand system 20db.

5. Wide range crushing.

In addition to variety of limestone, it can be used for crushing tailings, cobblestone, construction waste and other materials.

6. Environmental Friendly.

The system is equipped with advanced dust removal program, the working environment will be without any dust pollution.

7. Compact Structure.

100 ~ 200m2 (Transporting in parts available, finishing the installation and commissioning in a week normally), low height, the maximum height is 10 ~ 20 m.

8. High degree of automation.

Saving human resources greatly, because the control system is integrated in an operating room.

Dry Method Sand Making System parameter:

SJ-100 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~80mm | 120t | 0~4.75mm(>70%) | 150kW | |

Feeding system | 0~30~80mm | 120t | 20kW | ||

Discharge system | 0~3mm(product) | 80t | 0~2mm(>40%) | 15kW | |

De-dusting system | 15000m3/h(wind) | Powder quantity adjustable | Fine powder | 25kW | |

Sieving system | 0~30mm | 120t | 120t | 0~3mm;3~4.75mm;>4.75mm | 11kW |

Others | 15kW | ||||

Total power | 236kW | ||||

SJ-150 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~100mm | 160t | 0~4.75mm(>70%) | 220kW | |

Feeding system | 0~30~100mm | 160t | 45kW | ||

Discharge system | 0~3mm(product) | 110t | 0~2mm(>40%) | 30kW | |

De-dusting system | 20000m3/h(wind) | Powder quantity adjustable | Fine powder | 30kW | |

Sieving system | 0~30mm | 160t | 160t | 0~3mm;3~4.75mm;>4.75mm | 15kW |

Others | 20kW | ||||

Total power | 360kW | ||||

SJ-300 | Feed particle size | Feed quantity | Discharge quantity | Material particle size | Power |

The host system | 0~30~120mm | 320t | 0~4.75mm(>70%) | 400kW | |

Feeding system | 0~30~120mm | 320t | 60kW | ||

Discharge system | 0~3mm(product) | 220t | 0~2mm(>40%) | 45kW | |

De-dusting system | 40000m3/h(wind) | Powder quantity adjustable | Fine powder | 45kW | |

Sieving system | 0~30mm | 320t | 320t | 0~3mm;3~4.75mm;>4.75mm | 22kW |

Others | 20kW | ||||

Total power | 592kW |

Note:

1.These parameters of sand production make limestone as a reference base.

2.Feed requirements in accordance with international standards, stone moisture is less than 5%.

3.Sand production will change according to different stone and raw material.

4.Designed by site-specific, picture is only for reference.

FAQ

1. Our Advantage

We are one of the largest State-Owned Enterprises in China which established in 1984 , has 30 years experience in stone crushing and sand making industry , have rich experience , We have professional R&D design department and technical engineer , we can make the design and suggest the suitable machine as per customer’s special requirement and any products is customized .

2. Quality Guarantee

We have Strictly Quality-Inspection Department and we also can apply SGS and other Third-Party Agency to check the Products to make sure superior quality .

3. Payment Terms :

Generally we accept TT and LC , if project requirement , we can accept DP and LC After Sight .

4. After Sales Service

We can send our engineer and sales manager to your job site for work and installation direction and make training for your workers .

5. Time of Delivery

We can overdo work for the customer to make sure the fast shipment

- Q: In a fight between Arnold Schwarzenegger and Wesley Crusher from ST-TNG, who would win, how many rounds would it last, and what would the finishing move be?

- Wesley Crusher would win. It would last 14 rounds and Arnie would eventually succumb to Wesley Bone Crusher's Whiny Little Boy Move.

- Q: I'm going into 8th grade. Should i get a deluxe, super deluxe, or what? Which is the best made and which looks better? How much more can one hold than the other? What is the difference?

- It sounds like it to me. Is that a good thing or a bad thing that he likes you?

- Q: Cement and concrete production : how does it work ?The first diagram illustrates the different steps involved in the cement-making process while the second diagram shows the relationship of cement with other components in order to produce concrete.First, limestone and clay are passed through crushers and transformed in powder. Then, the powder is sent to a mixer. Next, it passes trough a rotating heater. After this, the remainder passes through a grinder and cement is obtained. Finally, the cement is put in sealed bags.The concrete production involves only one machine, that is the concrete mixer. Inside the concrete mixer it is put a combination of 15%, 10 % water, 25 % sand and 50% gravel. The concrete mixer rotates and once the components are well mixed, the concrete is ready to use.Overall, it is clear that cement production involves more machines but less raw materials than concrete production.

- he's yet to announce his retirement. each so oftentimes the form of sentence is deceiving. do away with the interest 'yet'. you do now no longer say, He has to announce, precise? yet incredibly you're saying, he's to announce.

- Q: What is the function of the sealing ring of the crusher?

- Mechanical seals, mechanical seals are mainly composed of the following four categories. 1. Main seals: moving ring and stationary ring. 2. Auxiliary sealing parts: sealing ring. 3, pressing parts: spring, push ring. 4, transmission parts: play skip and key or fixed screw.

- Q: What is the working space of the eccentric sleeve and the eccentric shaft of the cone crusher?

- After the taper crusher, the eccentric shaft sleeve and the bevel gear are stably loaded into the frame, the meshing clearance of the gear is measured by means of a lead screw or a rotating shaft. The Bush and the frame of the eccentric shaft sleeve, a large gap, and the eccentric shaft sleeve by rotating the straight bushing in always, so the cone crusher cone gear center, with the gap of the eccentric shaft sleeve and rack bushing half radius of circular motion, so in the actual gap value is bigger. If the backlash of the gear meshing is small, additional load will be generated on the gear and transmission shaft.

- Q: choose one of every category please:star trek tng or the original star trekkirk or picardvoyager or tngvoyager or the originaldata or spokenterprise ship or voyager shipdr. crusher or dr. pulaski-from tng

- TNG, Picard but I still love Kirk, TNG, original, Spock, Enterprise, Crusher, I hated the other chick.

- Q: The difference between a cone crusher and a counter blow

- Thus, the crushing wall of the broken cone is sometimes close to and sometimes leaves the surface of the mortar wall fixed on the adjusting sleeve, so that the ore is continuously impacted in the crushing chamber, and the crushing and the bending action are carried out to realize the crushing of the ore. The motor drives the eccentric sleeve through the bevel gear so that the crushing cone acts as a swing pendulum. The broken cone sometimes approaches and sometimes leaves the stationary cone to complete crushing and discharging. When the support is connected with the frame body, the spring is compressed by the spring, and when the crusher falls into the metal block, etc., the spring can generate compression deformation, and the foreign substance is discharged to realize the insurance and prevent the machine from being damaged.

- Q: Even a CAN CRUSHER would take up too much space!!! (at least, the ones I've seen.)Imagine if you will a living space comprising a small galley kitchen, small island, sofa, and coffee table. There is a small hallway to the side, and a small bedroom. Also a bathroom, but obviously not storing recyclables there. Imagine, then, two adults living in that space. We are NOT small.What do you do with 2 litre plastic bottles??? Weekend papers, JUNK MAIL (despite being on the don't-mail-me list, and having put stickers on the mailslot), freaking receipts...For whatever reason, we're not asked to sort. There's a chute for the garbage on our floor, so that's easy enough, but the recycling we wind up only taking twice a week (you get slimy hands chucking it on the way to work, don't you?). We live around the rest!

- You're lucky that you don't have to sort. Here's a few tips to keep recycling cleaner. -wash out all of your bottles and cans, smash them flat with your feet (you don't need a can crusher) and make certain they are dry before putting them in the bin. -flatten paperboard boxes -shred any paper with personal info (cc offers, receipts, etc.) -dedicate one trash can to the bottles and cans and line it with a bag. -Have a grocery sack or cardboard box for all of the paper goods. If your recycling drop off is on the way to the office, grab the bags and head out. if everything is clean in the bags, you will stay clean to. Carry a small pack of wet wipes with you to wipe your hands down after you drop them in the bin.

- Q: I need a creative way to crush a can, for a science project.

- Cause the can to be heated and then seal one end (the one that was opened) and then spray with cold ice water... The can will collapse...

- Q: Blower works fine. But all air blows up to windshield NOT through other options floor or horizontal vents when selected. How do I fix the problem?

- I'd try buying another new battery for it. Your new battery might have lost its power sitting around. If it still beeps, then I'd toss it, might be a warning system that something is malfunctioning. But I'm sure you know that a quick beep every minute means low battery.

Send your message to us

0-4.75mm Dry Sand Making System without any Powder in Site

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 60 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches