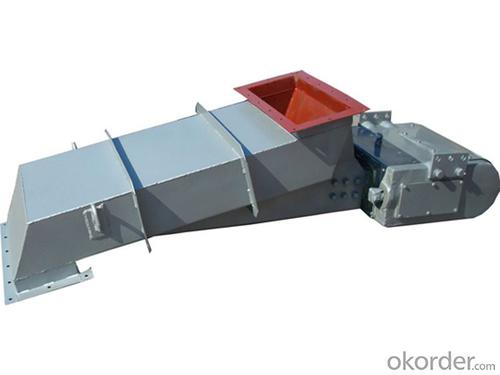

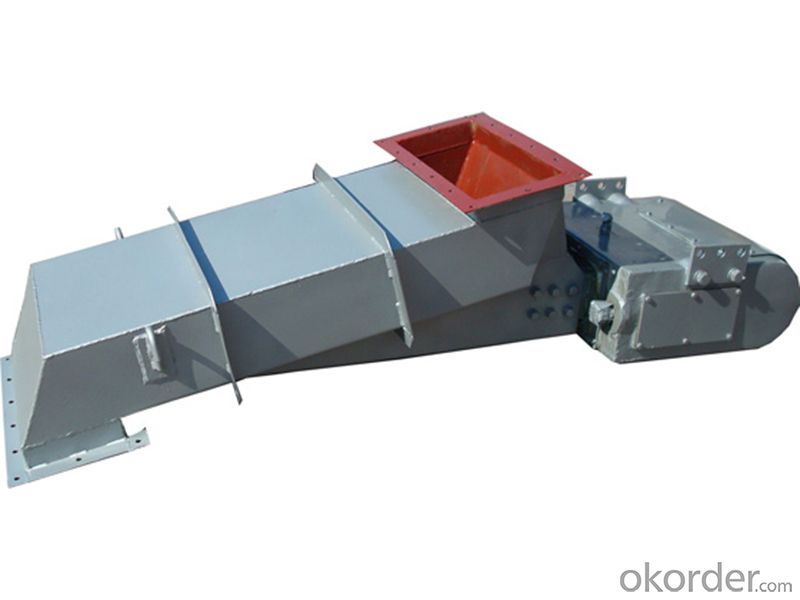

GZ type Electromagnetic vibrating feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

GZ type Electromagnetic vibration feeder

Product overview:

GZ type electromagnetic vibrating feeder used for the materials from the storage bin supply to the receiving device uniformly or quantitatively, is the necessary equipment to implement automated assembly line, divided into open type and closed type two. According to the requirements of the production of motor vibration feeder, hopper, conveyor.

Application:

1. Bulk, granular and powder-like material of the uniform continuous feeding.

2. Belt conveyor, bucket elevator, screening equipment, cement mill, crusher, grinder and the viscosity of the industrial sector of the powder feed material feeding device.

3. Automatic batching, quantitative packaging and etc..

4. Widely used in mining, metallurgy, building materials, coal, light industry, chemical industry, electric power, machinery, food, medicine and other industries.

Advantages:

1.Small size, light weight, simple structure, easy installation.

2.The two-body work in the low critical state, consume less energy.

3.Can instantly change and open and close material flow, to feed the high accuracy.

4.Can achieve centralized control of production processes and automatic control.

5.No lubrication, easy maintenance, low operating costs.

6.Can achieve frequent start and continuous operation.

Technical parameter table:

Model | Model | Capacity (t/h) | Feeding granularity (mm) | Amplit -ude (mm) | Volta-ge (V) | Working current (A) | Effective power (Kw) | |

Horizontal | Capacity | |||||||

Basic type | GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 0.06 |

GZ2 | 10 | 14 | 50 | 3 | 0.15 | |||

GZ3 | 25 | 35 | 75 | 4.6 | 0.20 | |||

GZ4 | 50 | 70 | 100 | 8.4 | 0.45 | |||

GZ5 | 100 | 140 | 150 | 12.7 | 0.65 | |||

GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 1.5 | |

GZ7 | 250 | 350 | 300 | 24.6 | 2.5 | |||

GZ8 | 400 | 560 | 300 | 39.7 | 4.0 | |||

GZ9 | 600 | 840 | 500 | 47.6 | 5.5 | |||

GZ10 | 750 | 1050 | 500 | 39.4*2 | 4*2 | |||

GZ11 | 1000 | 1400 | 500 | 47.6*2 | 5.5*2 | |||

Closed type | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 0.06 |

GZ2F | 8 | 11.2 | 40 | 3.0 | 0.15 | |||

GZ3F | 20 | 28 | 60 | 4.6 | 0.20 | |||

GZ4F | 40 | 50 | 60 | 8.4 | 0.45 | |||

GZ5F | 80 | 112 | 80 | 12.7 | 0.65 | |||

GZ6F | 120 | 168 | 80 | 1.5 | 16.4 | 1.5 | ||

- Q: The opening process of press filter from feeding to discharging is described briefly

- Close all piping valves and continue to remove extrusion pressure.After opening the filter, the filter press is opened and the cake discharge is carried out.

- Q: What's the simplest ore radio to do?

- The most simple ore radio, a three meters above the overhead antenna, a ground wire, a 2AP9 diode, a high impedance diode in parallel with the headset, headset received two world online, only listen to the strongest local Taiwan, if there is more than a strong one mix together.

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- Tangential feed -- from tangential direction is fed into the crushing chamber, the common good, not only crushed grain, also crushed small cake and chopped stalk and forage.

- Q: How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size and production capacity of crushing equipment, whether it is what it needs

Send your message to us

GZ type Electromagnetic vibrating feeder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches