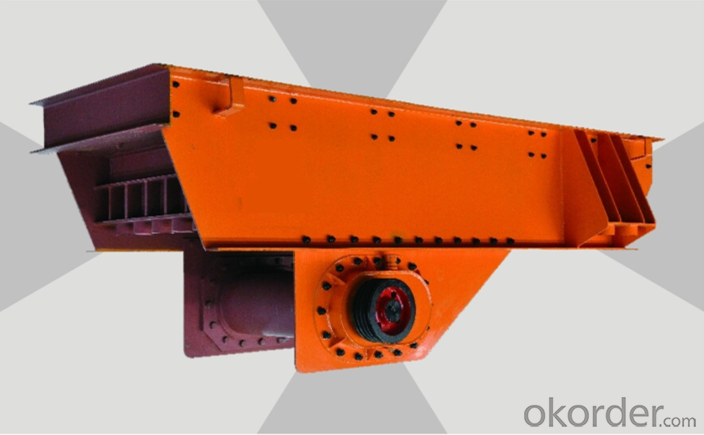

ZSW Vibrating Feeder,Mining Equipment, Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

This series feeder is straight line vibration feeder, adopting vibration exciter mode, it has the characteristics of stable vibration, reliable operation and long service life. It can be used for continuous, even feeding of crusher machinery; Promote and improve the crusher machinery’s capacity and continuous working ability, make it has the ability of preliminary sieving capacity for materials. ZSW vibration feeder is usually used in the feed of jaw crusher. Widely used in mineral processing, building materials, water conservancy, chemical industry and other fields of crushing and screening combined equipment such as feeding and batching from crushing, coal preparation, screening, transportation, packaging machinery.

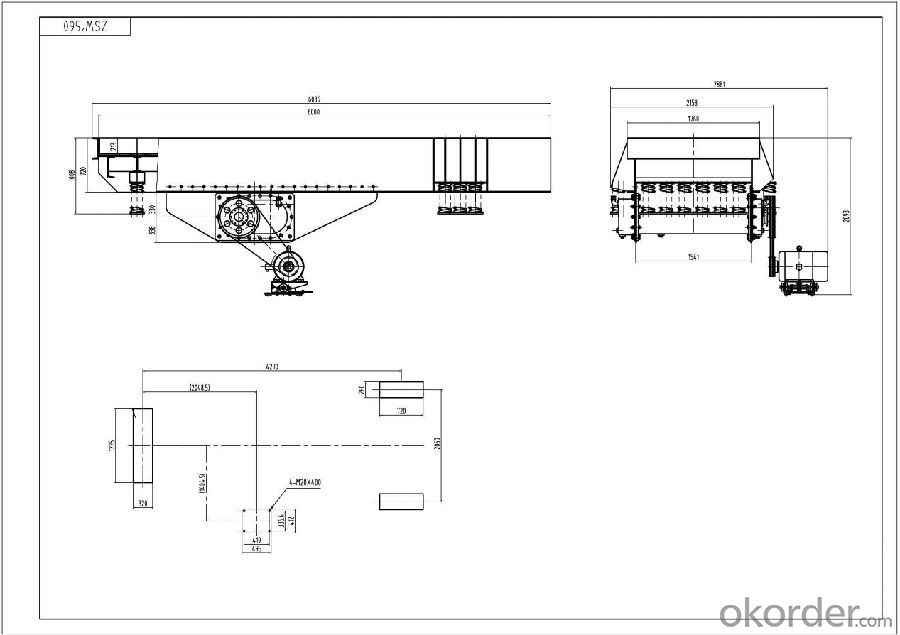

Overall Drawing

Technical Specification

Model | Max. Feed Size(mm) | Handling Capacity (t/h) | Power(kw) | Double Amplitude(mm) | Weight |

ZSW380*95 | 500 | 96-210 | 11 | 9 | 4.1 |

ZSW490*110 | 580 | 160-350 | 15 | 10 | 5.3 |

ZSW600*l30 | 800 | 400-560 | 22/30 | 10 | 7.5 |

ZSW600*l50 | 1000 | 460-615 | 30/37 | 9 | 8.7 |

ZSW600*l80 | 1200 | 600-1000 | 37/45 | 9 | 12.6 |

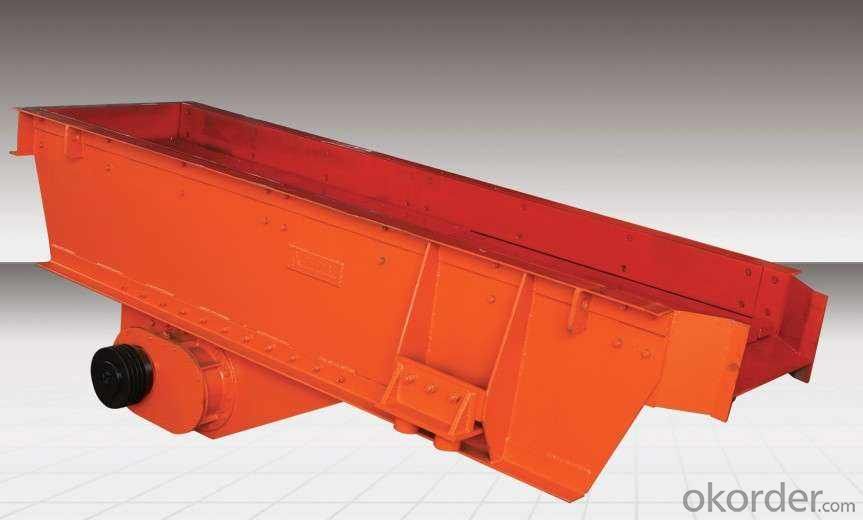

Function

The structure features of the double eccentric shaft exciter are adopted in ZSW vibration feeder to ensure that the equipment can withstand the impact of large pieces of material falling and has large feeding capacity. In the production process, the block and granular materials can be sent to the receiving device evenly, regularly and continuously from the storage bunker to prevent the feeding device due to uneven feed to encounter the system halted or crash problems; in the other hand, the service life of the equipment is prolonged. Feeder can be divided into steel plate structure and grate structure, the feeder which is steel plate structure is used in sand and stone production line, fed the material uniformly into the crushing equipment; The feeder of grate structure can be coarse screened for materials, making the system more economical and reasonable in preparation.

Feature

The vibration is steady and the work is reliable.

Special grid design to prevents material blocking.

The clearance of the grid is adjustable. Wear resistant parts are more enough to use.

Small materials are separated to prevent wear resistant be worn down from small materials, which can increase production.

Frequency control motor can be chosen for used to adjust the frequency, thereby changing the output, it is easy to control the feeding rate, and not need to start the motor frequently.

Working Principle

ZSW vibration feeder is mainly composed of vibration frame, spring, vibrator, motor vibration frame and motor. The vibrator exciter is composed of two special positions eccentric shafts meshed with gears and according to the mark to mesh the two gear when assembling. Two eccentric shaft is rotated by the motor drive, thereby the large synthesis straight excitation force be produced; Make the organism vibrate forcibly on the supporting spring, the material is driven by this vibration, sliding and throwing motion is carried out on the chute, so that the material moves forward to achieve the purpose of feeding. When the material passes through the sieve on the tank body, the smaller material can fall through the clearance of the screen, the effect of screening can be obtained without breaking through the next process.

Installation

The ZSW feeder shall be installed on the fixed foundation according to the required installation method. The wheels of mobile feeder should be wedged by triangular or braked by stopper before operation, so as to avoid sliding in work. When there are many feeder working in parallel, there should be a metre between the machine and the wall or machine and the another machine.

Before the use of the feeder, it is necessary to check the running parts, the belt buckles, the bearing devices and the protection equipment. The tightness of the tape must be adjusted to a suitable level before starting.

The feeder should start without load, after well running, the material can be fed. Operation after charging is prohibit.

When several feeder are connected in series and operation, should starting from the delivery end, sequential firing. After well running, the material can be fed.

When the belt deviation occurs in the operation, it should be stopped and adjusted, and must not be used reluctantly, so as avoid to wear edges and increase load.

The working environment and the temperature of the material to be sent shall not exceed 50 centigrade and below -10 centigrade. Materials containing acid base oils and organic solvents shall not be transported.

No pedestrians or passengers on conveyor belts.

Before stopping, the material must be stopped, and the belt can be stopped when the material is unloaded.

The motor of feeder must be well insulted. Do not pull and drag the cable of mobile feeder. The motor of feeder should be placed on ground.

The belt is not allowed to pull by hands when the belt is slipping, so as to avoid accidents.

FAQ

How much is the capacity of the equipment?

- Different specifications of equipment processing capacity will be different, the convention approved product of our company’s handling capacity is up to 1200t/h, it can also provide customized service according to the working conditions.

What brand does vibrator bearing use?

- Bearing adopts internal and abroad high quality brand. Regular co-operation branding is SKF, FAG (aboard brand).

What kind of vibrator lubrication mode is it?

- The vibrator adopts rare lubrication mode and the motor adopts high efficiency and energy-saving motor.

Does the equipment have coarse screening function?

- In the front of the sieving bar of this equipment is installed, and it can be carried out the coarse fraction to the ore.

Can the equipment withstand greater impact?

- The whole set of damping spring device is installed at the lower end of the feeding end of the equipment to withstand the impact of larger ore.

- Q: How about resin vibrating screen?

- The resin vibrating screen is a special high performance vertical vibration motor as power source, which is favorable for long-term uninterrupted operation. The parts of the body that come into contact with the material are all made of a stainless steel plate, durable and excellent in corrosion resistance and wear resistance. Cleaning is very convenient.

- Q: What is the influence of eccentric vibration of the vibrating screen on the rolling bearings?

- The vibration system consisting of bearings and eccentric systems can be considered as a single degree of freedom system. There is a certain value of the resonant frequency of the bearing shaft and the driven shaft system. The vibration of the silo wall is resonant if the excitation frequency is close to the resonance frequency. In addition, due to eccentric inertial force, the bending vibration will occur, and if the speed of the anti blocking device approaches the critical value, the bending resonance will occur.

- Q: What are the precautions for using a linear vibrating screen?

- When stopping the use of linear screen, the material must be stopped until the material of the vibrating screen and the vibrating motor are closed at the end of the screening so as to avoid waste of materials and reduce the difficulty of cleaning the straight line screen.

- Q: What is the difference between a circular vibrating screen and a linear vibrating screen?

- Circular vibration sieve and line screen work is not the same, the material on the screen of the line is jumping up and down and move forward, the trajectory of circular vibration sieve is an ellipse trajectory, two dice are not the same, and the shape is not the same.

- Q: Ask the TWB bearings? The crusher is used on vibrating screen

- Xi'an City gold Shengrui Electromechanical Equipment Co. Ltd is an authorized reseller TWB TWB! In case of demand, we can call for a visit!

- Q: How do I clean the shaker?

- Different materials, cleaning methods are also different

- Q: How to change the screen of vibrating screen?

- Ring again, loosen the ring beam universal pliers, screw hook lock.

- Q: What is the vibration of the shaker?

- It is the eccentricity of the vibrating screen, that is, the center of gravity of the vibrating screen does not coincide with the action line of the exciting force.It may also be caused by the looseness of a bolt. Check whether the connecting bolt is loose. If it is fastened, if it is not, it is caused by eccentricity, and only the counterweight is added to solve it.

- Q: How to use the drilling fluid vibrating screen and how to operate it?

- Start the shaker - supply - clear the online solid phase - stop the liquid before you stop - rinse the net - stop;

- Q: Difference between tailings dewatering screen and vibrating screen

- Tailings dewatering screen is vibration equipment with dehydration, transportation, low noise function, mainly used for coal, mineral processing, electric power, sugar, salt and other industrial sectors, the fine material for dry and wet type classification, dewatering, medium drainaging and sieve machine. Large processing capacity, high screening efficiency. The vibration sieve tailings dewatering transport, dehydration, vibration and other functions in combination.

Send your message to us

ZSW Vibrating Feeder,Mining Equipment, Feeder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords