LLDPE Geomembrane HDPE GH-I 2.0 Waterproof Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description

Our HDPE GH-I 2.0 waterproof board was proved as good physical and mechanic performance, ultra-violet radiation, oil and salt, alkali and corrosion resistance, high and low temperature resistance, non-toxicity, long operational life, good waterproof, complete width and thickness specifications, low cost and simple construction.

1.used in landfill caps

2. base liner applications under roads, railways,

3.secondary containment for above ground tank farms,

4.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic:

1) , Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

2) ,Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

3), Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

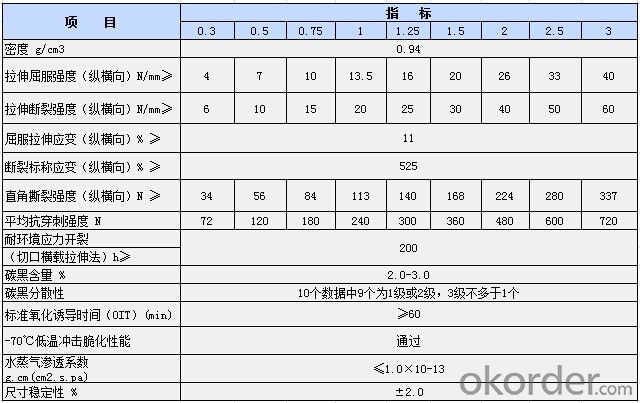

3.Product Specifications:

1.thickness : 2.0mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Tensile elongation at break 600%

4.Material: HDPE.

5.Color: Black white or as you required

4.Reference Picture

- Q: What are the limitations of using geomembranes in construction projects?

- One limitation of using geomembranes in construction projects is their susceptibility to puncture or tearing. If not properly installed or protected, sharp objects or construction equipment can easily damage the geomembrane, compromising its effectiveness as a barrier. Additionally, geomembranes can be challenging to install on uneven or sloping terrain, as they require a smooth and stable surface for proper functioning. Moreover, geomembranes may be vulnerable to UV degradation over time, necessitating regular maintenance and replacement. Lastly, their high cost compared to other construction materials can be a limiting factor for some projects.

- Q: Are geomembranes suitable for use in geothermal energy projects?

- Yes, geomembranes are suitable for use in geothermal energy projects. Geomembranes are flexible and durable materials that can effectively contain and control fluids, making them ideal for lining geothermal well pads and reservoirs. They provide a barrier against fluid leakage, prevent soil contamination, and help maintain the integrity of the geothermal system. Additionally, geomembranes have excellent thermal properties, which can contribute to the overall efficiency and performance of geothermal energy projects.

- Q: What are the precautions for the construction of the slope area of the cesspit?

- The construction method of geotextile/geomembrane: 1 flatness: ±2cm/m2, flat and straight; 2 compactness: 95%, after grinding, pave geomembrane on the surface; 3 vertical and horizontal gradient: Longitudinal and transverse slope should be above 2%, boundary and structure of the landfill bottom must be beneficial to diversion of leachate; 4 cleanness: No roots, rubble, gravel, concrete particles, such as sharp edges shall appear within vertical depth of 2.50cm . Climate requirements while paving: 1. Temperature: 5 - 40℃ is appropriate. Taking into account thermal expansion and cold contraction of the geomembrane, according to experience, when the weather is cold, geomembrane pavement should be tight; in hot weather should be loose; but it should be noted that, in summer, high temperature should be avoided at noon. 2 wind and rain: If the wind scale is over force 4 wind or it's raining, the construction should be stopped; When wind is lessened, it is proper to hold down geomembrane with sandbag so as to facilitate construction. Construction and installation of HDPE geomembrane: 1 construction and installation process of HDPE geomembrane. 2 tailor and transportation: According to the records of laying base measurement , cutting large bundle number of geomembrane should be marked and recorded and then carried to construction site according to their number.

- Q: What are the requirements for geomembranes used in heap leach pads?

- The requirements for geomembranes used in heap leach pads include a high level of chemical resistance to withstand the aggressive chemicals used in the leaching process, excellent puncture resistance to prevent leaks, low permeability to minimize fluid migration, and UV resistance to withstand prolonged exposure to sunlight. Additionally, the geomembranes should have good tensile strength and flexibility to accommodate any subsidence or settlement in the heap leach pad.

- Q: How do geomembranes prevent liquid evaporation in floating covers?

- Geomembranes prevent liquid evaporation in floating covers by forming a barrier that effectively seals the surface of the liquid. This impermeable layer prevents the escape of moisture or vapor, thus minimizing evaporation and ensuring the liquid remains contained.

- Q: How do geomembranes improve water efficiency in agricultural irrigation systems?

- Geomembranes improve water efficiency in agricultural irrigation systems by preventing water seepage and evaporation. These impermeable liners act as a barrier, effectively containing the water within the irrigation area. This reduces water loss due to seepage into the ground and minimizes evaporation, ensuring that a larger portion of the water reaches the plants' root zone. As a result, farmers can optimize water usage, reduce water waste, and improve overall irrigation efficiency in their agricultural operations.

- Q: How to tear down polarizing film from display?

- Processes of tearing down polarizing film from display: We need a few high-quality blades, bamboo sticks, absorbent cotton and a little alcohol. After the screen is torn apart, take down the back shroud, the screen can be just put in the frame and needn't to be put out, and lay it on the table flatwise. Viewing screen corner, you will find that at the gluing between edge and glass, cut along glass with a blade, use tweezers lift cut polarizing film, and take a absorbent?cotton bamboo stick to dips a little alcohol and swipe at the cut gap, the polarizing?film will slowly separate from the glass till completely peeled off. You can also use water, but you have to prevent the water from flowing to the back panel. After peeling off polarizing film, the adhesive residue on the glass screen should be cleaned up.

- Q: what are the diamond film?

- Diamond film is a mobile phone protection film. diamond film is in the middle layer, but it will not feel , the diamond film matte feel better compared. Diamond film will obviously be displayed outdoors under sunlight, having small dots shining like dimonds. Diamond film uses special silica?gel to maintain transparency without bubbles. it is glittering and translucent in the sun or bright light, it is eyecatching like diamonds. in case of scratching. Combined diamond film with IPAD, it will become a new fashion.

- Q: Are geomembranes suitable for use in oil spill containment?

- Yes, geomembranes are suitable for use in oil spill containment. They are impermeable barriers that can effectively prevent oil from spreading and contaminating surrounding areas. Additionally, geomembranes are durable, flexible, and resistant to chemicals, making them ideal for handling the harsh properties of oil spills.

- Q: What concrete acceptance criteria?

- Usually standard curing time for a 28-day delivery, three days ahead of time can not be more than 28 days, or to rebound, count overage of the same curing condition at 600 ° or more, usually from the day of pounding the concrete when the temperature began to accumulate scene, it can go up to 600 degrees sent. Condition number of days with not less than 14 days and not more than 90 days. The following is a sample batch project the number of samples per test block 1. Concrete Compressive mixing 100 and not more than 100m3 of concrete mix with less than 1 second 2. Each work shift mixing of the concrete mix with less than 100 3. when at least once a continuous casting played 1000m3, the same mix of concrete not less than once every 4 200m3 each floor, the same mix of concrete not less than once every 5 Pile Concrete pouring 50m3, smaller than 50m3 of piles, each pile must have a group of not less than 1 6. each batch of concrete form removal test at least one group of diaphragm wall 7. the excavation, each 50m3 each groove section or not less than 1 8. ground engineering construction of concrete test blocks for each layer (inspection Lot) per 1000m2 sampling of not less than 1, each additional 1000m2 shall be taken by 1, by less than 1000m2 1000m2 meter. When changing the mixing ratio, a corresponding increase in the sampling frequency and the first use of concrete mix opening identifying at least one group

Send your message to us

LLDPE Geomembrane HDPE GH-I 2.0 Waterproof Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords