HDMI Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 800000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDMI cable, DVI cable, VGA cable, Optical fiber cable, USB Cable; Rca cable

The main products of our company are as following:

HDMI cable, DVI cable, VGA cable, Optical fiber cable, USB Cable; Rca cable

Computer Cable, Hdmi Cable, Hdtv Cable, VGA cable, DVI cable

Audio/Video Cable, Video Cable, Pc Cable,

Data Transfer Cable, Data Cable, Digital Device Cable,

Hdmi Cable, Hdmi, Dvi Cable, Hdmi To Hdmi Cable, Hdmi-Hdmi Cable, Hdmi-Dvi Cable

Description

HDMI (High Definition Multimedia Interface) provides an interface between any HDMI-enabled audio/video source, such as HDTV, PS3, Blue Ray DVD players, XBox360 Elite, Home Theater, projector, Dish receivers and all other device with HDMI input. It transmits all ATSC HDTV standards and supports 8-channel digital audio, with bandwidth to spare to accommodate future enhancements and requirements.

Features:

HDMI 19 PIN male to HDMI 19 PIN male cable.

Double-color PVC moulding shell.

Certified HDMI 1.3b, back compliant with all previous HDMI versions, Support All HDMI Devices, transfers at 10.2 Gigabytes per second.

Supports 1080p Full HD picture quality and Supports up to 1600p (future proofed).

24K Gold plated connector for the best conductivity.

Use Oxygen free copper conductor to maximum signal transfer and minimize interference.

With Triple layer copper braided shielding to ensure lossless data transmission.

Buyer Selection

1. Gauge of cable: 30AWG, 28AWG, 26AWG or 24AWG.

2. Cable OD: 8.2MM, 7.3MM, 6.0MM, 5.5MM.

3. Cable length: 0.1M, 1M, 2M....20M

4. Ferrite rings for resisting EMI.

7. Shell Material: single-color PVC moulding, Double-color PVC moulding, Zinc alloy , Aluminum alloy.

8. Connector: Golden plated or Nickle plated

Similar Cable Available

VGA

HDMI / HDMI

DVI / VGA

DVI-D Single Link Cable

DVI-D Dual Link Cable

DVI-I Single Link Cable

DVI-I Dual Link Cable

DVI / HDMI

We can offer you various of Computer Connection Cable, including

Network RJ45 Cat5e, Cat6

Printer Cable (Convensional, IEEE1284)

Monitor Cable ( HDMI, DVI, SVGA, RCA, 3.5mm)

USB Cable (USB A / B, USB A M / F, USB A / Mini 5P)

Firewire IEEE1394 (4P, 6P)

Keyboard/Mouse Cable (DIN6, DIN8)

Modem Cable (DB9, DB15, DB25)

IDE Flat ATA / SATA

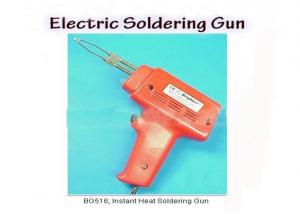

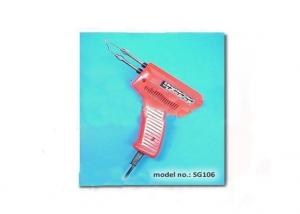

- Q: Electric iron, etc. is not inductive load?

- Electric cookers, electric furnaces and electric irons are resistive loads.We usually use inductive loads, such as electric drills, refrigerators.Capacitive load a capacitive load, consisting of two plates that are insulated from each other;Resistive load -- a load that exhibits pure resistance, such as an incandescent lamp;Inductive load -- a load that exhibits inductance, such as a transformer, that is loaded by a coil.Capacitance is capacitive load, for example, the connection of capacitors in the power grid can improve the power factor, which is very helpful for the safe operation of the power grid. Inductive is inductive loads, such as motors, televisions. In the power grid, moderate load, resistive load is purely resistive load cases, incandescent bulbs, electric stove, water heater, in the power grid, load) is inferior

- Q: What is the function of rosin in the use of electric irons?I didn't use any rosin when I used it. I didn't know how to use it

- You are factory welding or repair ah tin wire and now there are rosin can generally be if the repair welding is suggested to be used in the production of some rosin paste. It will not because of the easy to cause the circuit board rosin appearance after welding unless the cleaning circuit board is mainly rosin flux can greatly improve the welding effect the analogy is detergent washing washing out of the bowl is clean with a detergent bowl cleaner repair if small solder joints can be directly used electric iron stick in the rosin and large welding solder joint can be directly put small pads of rosin in welding production then directly welding.

- Q: Tired of... For a soldering iron let me be someone else's face! Did not expect to work for other people so poor! Only know that reading is good! Please help, teach me how to use and tell me why black black? How to do?? I don't want to see others face! Thank you...

- It is better not to use a blade or sandpaper to make the original coating of the soldering iron lose its original antioxidant. The best way is to use a dedicated sponge absorbent dip on the line, the first time to use more iron to eat some solder

- Q: Electric irons have internal heat and external heat What is the difference between them and how to distinguish them?

- The internal heating element is inside the copper head, and its heat efficiency is relatively high. The outside heat type electric heating wire is outside the copper head, and the power of the iron is related to the metal area to be welded. Small power electric soldering iron, suitable for welding small parts. Such as welding semiconductor device and integrated circuit power is not greater than 30W. High power iron welding larger.The greater the metal area, the greater the power of the iron used. The internal heating type heater, a large head, short service life, are usually small capacity; external heat slowly, small head, long service life, can be used for large capacity, such as: 300W1.Difference between internal heating and external heating electric irons:1, mainly in the different heating methods.2, they use the shape of the iron head, the former is hollow cylinder, and the latter is solid rod.3, the former warm-up time is shorter, but the temperature is slightly greater, especially small power type; relatively, the latter warm-up time is longer.4, the former leakage is slightly smaller than the latter.

- Q: Isn't it normal? It's all red

- The tip temperature is too high or the tip coating, and then burn would have severe oxidation and perforation, buy a nice tip, you can look at the green tip

- Q: Why is it so hard to weld? Instant welding is not firm, what should I do? What's the trick?

- Estimate that you are a novice, wire and copper bar is very good welding, said the method, but also try more, slowly understand, or else it can not be welded.1, the wire and copper strip welding surface polished bright.2, the rosin into powder, bubble point of alcohol, that is, rosin solution (yellow thick). Apply to wires and jump together. Or directly pour rosin powder in two places, slightly hot, melt on the line. This step is necessary, or it won't be welded.3, the copper strip and wire together. The iron head slightly against the copper wire, stretch into melted, saw smoke coming out, can take away the iron, 5, 6 seconds after the solder solidification is good. Remember to solder the wires around, so it's secure.4, welding wire better. With active welding wire.

- Q: What about the tin on the soldering iron?

- First polish the iron head, shine, smooth, and show the true color of copper. Then, the electric heating, before the solder has reached the melting point, it should be frequently dipped in rosin, to protect the fresh surface, to prevent oxidation. When the temperature reaches the point of the solder, dip the rosin into it and rub it back on the solder so that the soldering head is soldered. Repeat it several times to get good soldering.

- Q: I welded the motor coil joint with electric iron. Why couldn't it be welded?

- 1, welding technology is immature, 2, electric iron power is too small, 3, material

- Q: Electric irons, hot melt guns and electronic components can be checked through the high-speed rail station?

- Article fifty-second of the railway transportation regulations: the following items shall not be brought into the vehicle:1. countries prohibit or restrict the transport of goods; 2. provisions of the laws and regulations of dangerous goods, ammunition and the carrier can not identify the nature of the chemical products; 3. animal level prevent public health (including odor smell) of the goods; 4. vehicles can be damaged or contaminated items

- Q: Electric soldering iron, mainly welding some TV, audio, amplifier power?

- 35W enough, welding time can not be too long, otherwise it will damage the device. Clean the iron head regularly and hang the tin.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDMI Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 800000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches