Gypsum Board Light Gauge Joist Stud And Track Roll Former Metal Aluminum Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

1, Production description:metal stud roll forming machine

C channel, stud, track, runner, U channel, Drywall system roll forming machine width adjustable

2, Machine introduction

INTRODUCTION

LMS roll forming machine which takes the COPRA, designing software for cold rolling production and applies for the first step of rolling design, calculation, molding technique simulation, blueprint optimization and roller design to rough molding management, digital machining and quality control. LMS applies for the COPRA in the whole process. The greatness of COPRA is combined with LMS's great experience of twenty years completely and this make LMS be with might double in production for clients. Realize your dream with CORPA.

3, Machine quotation

Quotation: FOB Guangzhou, China.

Roll forming machine(PLC control or common control) Price: will be confirmed after receiving your specification & profile drawing.

Payment term:40% down payment, and 60% balance payment before shipment by T/T.

Delivery time: 75 days after 40% down payment by T/T.

4, Machine specification

Here's the specification for the machine which we made for other clients before, please kindly check for your reference, as well as the photos.

One complete set of production line consist of following units:

Main Technical Parameter:

Thickness:0.45-0.8 mm

Profile width x height:30/60mm x 30mm

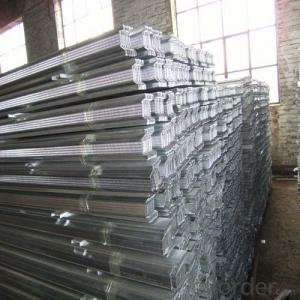

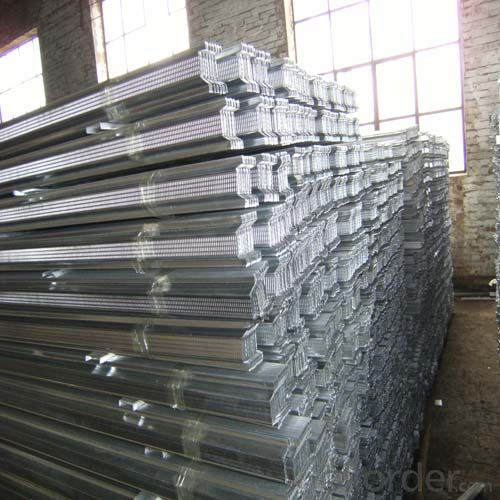

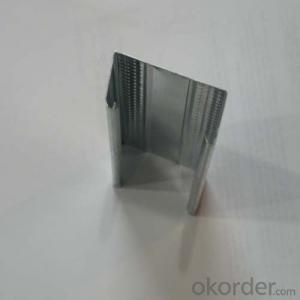

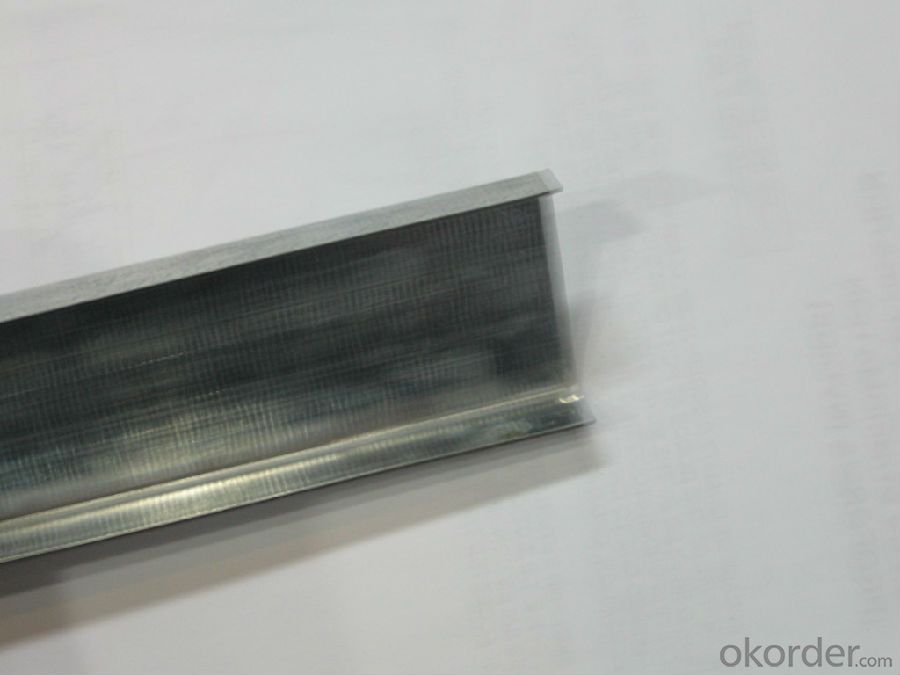

3.Image

4.Detailed Specification

5.FAQ

COMPONENTS AND DATA:

A. Decoiler 1 set

Loading capacity: 2 tons

Outer diameter: ?1400mm

Innder diameter: ?400mm-?450mm

Decoiling width: 400mm

Manual expansion

The machine can make more than one sizes: the width is adjustable by using the spacers as indicated in the following photos:

B. Roll Forming Machine 1 set

Roller stations: 14 groups Material of roller: Gr 15 steel

Heat treatment of roller: HRC55-57°

Surface of rollers has been polished.

Material of coil strip: GI,STEEL PLATE

Thickness of coil strip: 0.45-0.8MM

Width of coil strip: ACTUALLY USED

Diameter of roller shaft: ?40mm, made of 45# steel

Pinch wall thickness 22mm

Driven method: Gear and chain

Main bearings: 60207

Bearings thickness 35mm, 45# steel HF surface treatment

Power of main motor: 5.5 kw, cycloid pin reducer

Forming speed: 12m/min

Water coolant system

- Q: How to install damping sound insulation felt

- Noise board installed C100 light steel keel, keel on the inside of the nail pad a layer of sound insulation felt, to avoid rigid connection, keel gap filled with weight 40,35 two-layer sound-absorbing cotton

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- My family on the 85-year house, a lot of people in the district to do solid wood flooring, also used very good, no see who said their own floor problems. Did you knock on the wall? 24 walls are load-bearing, you can not knock, even if you want to knock, but also I-beam or channel support, the longer the wall, just the more important specifications, we are all of these houses are prefabricated panels, Direction, take the wall is absolutely can not knock, there will be a lot of dangerous risks.

- Q: 75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Main production 75 wall light steel keel, 100 wall light steel keel, ceiling card type main dragon, 50 pay dragon, 50 main dragon, 60 main keel, 60 pay dragon, 38 main dragon, triangular keel, galvanized ceilings , Paint smallpox keel, aluminum wind Tsui, gong rod, the keel accessories and other products.

- Q: Light steel keel wall circuit how to wear pipe

- 1, to C-type vertical keel on the threading hole as the basis, first determine the direction of the upper and lower ends of the keel, try to align the threading hole. Vertical keel length size, should be measured according to the size of the scene. The premise is to ensure that the vertical keel can be along the ground, along the long keel slot slide. 2, light steel wall vertical keel installation spacing, according to the actual width of the panel size and wall structure design may be. 3, vertical keel installed in place, should ensure that the vertical. Door and window openings should be taken double row of vertical keel reinforcement. When the design requirements for the steel connection, the vertical keel and the edge along the top keel of the fixed, the application of self-tapping screws or shaft rivets to connect. sixth,

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- The effect is certainly not the same or the cement mortar is really some wall after the installation of the socket is not vague. The

- Q: Light steel keel wall Why use gypsum board to do grass-roots level?

- It is not necessary to use gypsum board but gypsum board there are many other materials can not replace the advantages of easy paint on the paint, such as latex is also its weight is more suitable for the keel does not have too much pressure on the pressure there are other advantages One by one in detail the gypsum board used in light steel keel partition is a good choice.

- Q: How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

- Q: Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent the brush at the brushing of latex paint, keel and wall connection more than a few nail fixed

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- The original piece of putty knock down, from the new batch of putty on it

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Light steel keel level can be used in the ceiling, can also be used in the partition, Wood keel can also be cut off the ceiling can be done.

Send your message to us

Gypsum Board Light Gauge Joist Stud And Track Roll Former Metal Aluminum Drywall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords