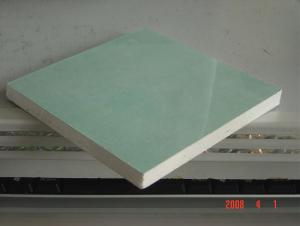

Gypsum Board 8.5mm

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Main Material: Gypsum Powder

Normal size: 2440x1220mm, 2400x1200mm

Normal thickness: 7, 8, 8.5, 9, 9.5,10, 12, 13, 15mm

Edge: Square, Tappered

Category: Regular, Fire resistant, Moistureresistant, Water proof

Performance: Fire-resistance, Moisture-resistance,Water-proof, Heat-preventing

Specifications:

1) Sepcial healthy breath function

2) Cost effective and more reliable, easy to install

- Q: There's a substantial dent (bordering on being a deep crack/hole) in the middle of a 3 square meter piece of painted plasterboard. I need to repair it with something durable as it's in a prominent place and thus am not sure plaster will suffice. On-top of that it will need to be painted. What should I use?

- I would paint it with a flat latex paint. That will help hide some of your mistakes. Good luck!

- Q: Is a hand drill suitable for drilling internal walls? (plasterboard)?

- A hand drill should work fine for wallboard internally but as another poster indicated, you should be aware of wiring or plumbing behind the wall. You can also use a sharp or semi-sharp object to punch holes in hollow walls to add screw anchors to hang pictures and shelves, etc. I've used awls, nailsets and even a philips screw driver to do this.

- Q: How long is a single layer of fireproof gypsum board refractory?

- Fire limit refers to the light steel keel steel structure with gypsum board full system of fire resistance. Rather than a single finger gypsum board. Ordinary 9.5mm single-layer fire at 1.5h. 12mm can reach 3h of fire.

- Q: Lots of water dripped through and there are stains in the plaster swirl ceiling. No visible bubbling or damage though besides the stains. Should I be worried about mold in an interior (no insulation) ceiling? Is it important to cut out the stained plasterboard ceiling?

- If you are absolutely certain the leak has been fixed and there is no more water dripping... 1. Place a fan facing toward the ceiling for about a week or as long as it takes to make sure the ceiling is completely dry. 2. Paint the stained area with Killz. (Not sure of the spelling but it's a water stain retardant) Let it dry overnight, regardless of what the directions say telling you it's dry in less than two hours. 3. Paint the surface again with Killz 24 hours later. 4. Wait 24 hours to see if the stain is visible. If it is, paint another coat of Killz. 5. If the stain is undetectable, wait 48 hours and paint the ceiling with with the color of your choice. A second coat of paint may be required.

- Q: Back blocking does not seem possible when the walls are clad first Similarly can I join fibre cement sheeting on a stud

- Fastening to any solid lumber is preferred. As long as they are flush with the studding, I don't see the issue.

- Q: I had some water damage to the ceiling of a small bathroom and need to remove the plaster, but I don't want to invest in a reciprocating saw (plus they're scary to use overhead).

- you could also try a rotozip.

- Q: Gypsum board ceiling and mineral wool board ceiling construction on the construction of the two construction practices are not the same, if not to believe that point

- That gypsum board called the top of the wooden keel frame structure, the surface with gypsum board finishes, that mineral wool board seems to be the same with the aluminum plate hanging ceiling practice seems to be the same. Is to use light steel keel frame, the mineral wool board embedded in where!

- Q: we want to put up hooks to hold the rod for curtains, but aren't sure what screws to use to keep the hooks in place. also, i'm thinking it might be plaster, but what are the options to use to help the screws stay firmly in the wall? the last time i tried this on a wall, the screws ended up coming out of the wall later and it was easy to just pull them out. any helpful advice is greatly appreciated.

- Plasterboard and drywall both mean the same thing, so does sheetrock for that matter. Drywall is the term most people use. I wouldn't be surprised if you aren't using plaster to mean the same thing, although it's not, but plaster hasn't been used in the U.S. much for 50 years or more now (maybe since the '30's? I've only seen it in old houses, and one custom builder that was still using it a decade ago.) There are numerous types of screw anchors sold for use in drywall. I think the best is a dry wall anchor that you first drill a hole for, insert, and then tighten a screw into. You can put them anywhere, and they hold pretty good. Other people use toggle bolts, or plastic screw anchors, there's probably other choices too. Hardware stores always have these items in stock.

- Q: Can gypsum board be insulated?

- Ordinary paper gypsum board with fire, heat insulation, sound insulation, stability and so on. Bayer positioning G30 health board, positioning 30% of the provincial workers, and according to the actual needs of the human body, adjust the indoor temperature and humidity, experts have been hailed as "breathing" gypsum board

Send your message to us

Gypsum Board 8.5mm

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords