Membrana Geotextil Ground Control Fabric/Landscape Fabric for Garden

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

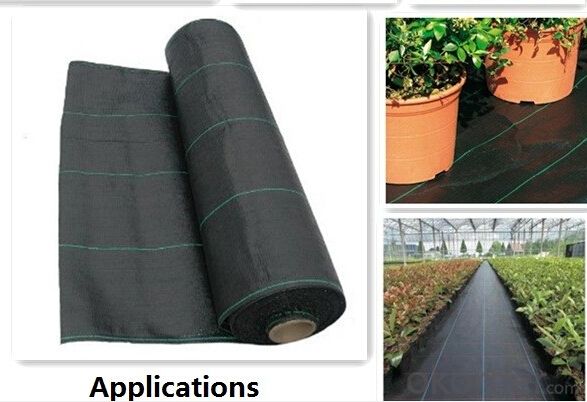

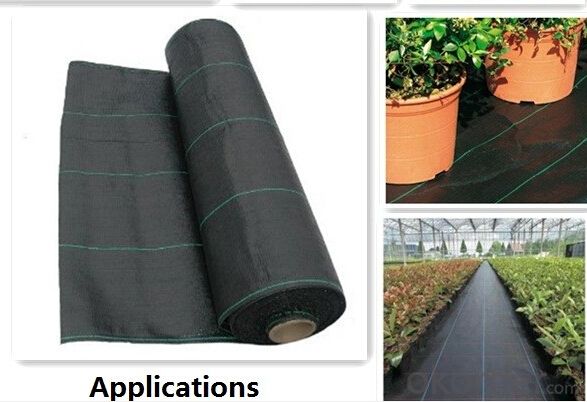

1. Landscape Fabric Description:

It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.They are permeable fabrics, which allow air, water and nutrients to pass through, and designed to block out the sun to reduce photosynthesis and stop weed growth.

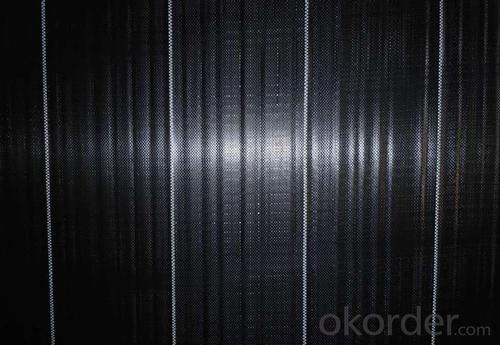

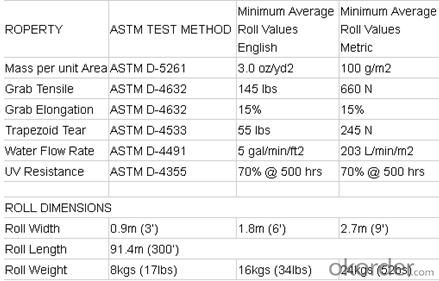

2. Landscape Fabric Specification:

3. Landscape Fabric Functions and Features:

1)Excellent weed control

2)Excellent UV resistance

3)Moisture,fertilizers,air reach plants to allow for healthy soil

4)Good water and air permeability

5)Exceptional toughness and strength

6)Durable,tear-resistant,anti-rot and anti-mildew

7)Light weight,easy to install,follows natural ground contours

8)Ideal for use in landscaped beds,under decks and walkways

9)Fashionable design,high quality,competitive price

10)Long service life

4. Landscape Property:

1) Light weight, high strength, low elongation, easy to construct.

2) Reinforcement, separation, drainage and filtration, fencing function, etc.

5. FAQ:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2:Can you send samples to us ?

A2:Yes , free samples could be provided , but customer need pay for the freight cost . After order placed , the freight charge could be refund .

Q3:What’s your Payment term ?

A3:T/T , L/C , Western Union,Paypal ...

Q4:What’s your manufacture process time ?

A4:Usually within 20 days.

- Q: How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by acting as a barrier between the soil and external forces. They distribute load and stress more evenly, preventing excessive compaction by promoting better soil structure and drainage.

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stabilization. They act as a barrier that prevents soil particles from being washed away by water or eroded by wind. This helps in maintaining the integrity and compactness of the soil, leading to improved consolidation and increased load-bearing capacity. Additionally, geotextiles can also distribute the applied load more evenly, reducing differential settlement and promoting a more uniform consolidation process.

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the porosity of the fabric, the thickness and density of the fibers, the weave or structure of the fabric, the surface roughness, and the presence of any clogging or fouling agents.

- Q: What are the types of geogrids?

- Geogrid type is a lot of it, steel-plastic geogrid / convex knot steel-plastic geogrid / overall plastic geogrid / fiberglass geogrid, etc.

- Q: Can geotextiles be used for reinforcement of landfills?

- Yes, geotextiles can be used for the reinforcement of landfills. Geotextiles are permeable fabrics that are used to improve the stability, drainage, and filtration of soil in various applications, including landfill construction. They are often employed to prevent soil erosion and provide support to the landfill structure, enhancing its overall stability and longevity.

- Q: What are the factors that affect the effectiveness of geotextiles in erosion control?

- The factors that affect the effectiveness of geotextiles in erosion control include the type and quality of the geotextile material, the installation method and technique, the slope gradient and soil conditions, the presence of vegetation, and the level of maintenance and monitoring.

- Q: Can geotextiles be used for soil stabilization?

- Yes, geotextiles can be used for soil stabilization. They are commonly used to reinforce soils and prevent erosion, providing stability to slopes and embankments. Geotextiles help to distribute loads, increase soil strength, and improve drainage, making them an effective solution for soil stabilization projects.

- Q: Can geotextiles be used in water retention projects?

- Yes, geotextiles can be used in water retention projects. Geotextiles are permeable fabrics that can help in water filtration, drainage, and erosion control. They can be used to line reservoirs, ponds, or other water retention structures to prevent soil erosion and retain water.

- Q: What is the length of the lap in the geotextile in the tunnel?

- Lap 20 cm Huazhi geotextile material answer

- Q: How about the geotextile pond

- You said to cover the fish pond, I understand is to build the bottom of the fish pond, but the use is not geotextile, but the composite geomembrane, the film is generally two layers of geotextile in the middle of a layer of geomembrane, , And geomembrane on both sides of the geotextile can prevent the bottom of the sharp objects pierced the geomembrane.

Send your message to us

Membrana Geotextil Ground Control Fabric/Landscape Fabric for Garden

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords