FRP Pultrusion Profiles Gritted FRP Grating-1/12 Inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

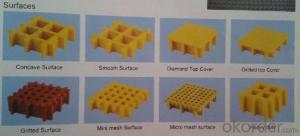

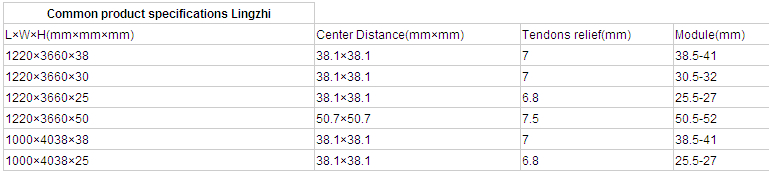

Specifications

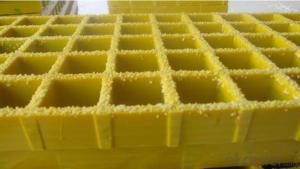

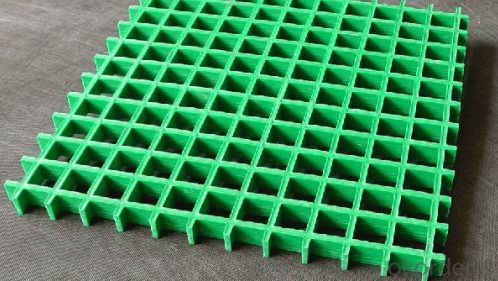

fiberglass mesh grating

1.meet ASTM E-84 AND ISO9001

2.anti-corrosion floor

3.anti-conductive

4.walkway,platform,trench cove

fiberglass mesh grating

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

Panel Size:

- Q: How do FRP pultrusion profiles perform in corrosive gas environments?

- FRP (Fiber Reinforced Plastic) pultrusion profiles have excellent performance in corrosive gas environments. The unique properties of FRP, such as high corrosion resistance, make them highly suitable for applications where exposure to corrosive gases is a concern. FRP pultrusion profiles are typically made from a combination of glass fibers and a resin matrix, such as polyester or vinyl ester. These materials are inherently resistant to corrosion and do not react with most corrosive gases. As a result, FRP pultrusion profiles can withstand exposure to a wide range of corrosive gases, including sulfur dioxide, hydrogen sulfide, chlorine, and many others. Moreover, FRP pultrusion profiles offer superior durability and long-term performance in corrosive gas environments. They do not rust, corrode, or degrade over time, unlike traditional materials like steel or aluminum. This corrosion resistance ensures that FRP profiles maintain their structural integrity even in harsh environments, reducing maintenance and replacement costs. Additionally, FRP pultrusion profiles can be manufactured with specific chemical-resistant resins and additives to enhance their performance in highly corrosive gas environments. This customization allows for tailoring the FRP profiles to meet the specific requirements of the application, ensuring optimal performance and longevity. Overall, FRP pultrusion profiles are an excellent choice for corrosive gas environments due to their exceptional corrosion resistance, long-term durability, and customization options. They provide a reliable and cost-effective solution for industries such as chemical processing, oil and gas, wastewater treatment, and many others where exposure to corrosive gases is a concern.

- Q: Are FRP pultrusion profiles resistant to jet fuel?

- Yes, FRP pultrusion profiles are generally resistant to jet fuel.

- Q: Can FRP pultrusion profiles be used for structural applications?

- Yes, FRP pultrusion profiles can be used for structural applications. They are commonly utilized in various industries such as construction, automotive, aerospace, and marine. FRP pultrusion profiles offer high strength-to-weight ratio, excellent corrosion resistance, and durability, making them suitable for structural components like beams, columns, and trusses. Additionally, they can be designed to meet specific load requirements and offer design flexibility.

- Q: What are the different shapes and sizes of FRP pultrusion profiles available?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are available in a wide range of shapes and sizes to cater to various applications and industries. Some of the commonly available shapes include: 1. Square and rectangular profiles: These profiles are available in different sizes and are widely used in construction, infrastructure, and industrial applications. They offer excellent structural strength and can be used as beams, columns, or other load-bearing elements. 2. Round profiles: Round FRP pultrusion profiles are often used as structural supports, handrails, and guardrails. They are available in various diameters to suit different requirements. 3. I-beams: FRP I-beams are popular in the construction industry due to their high strength-to-weight ratio. They are often used as structural members, supporting elements, or floor joists. 4. Channel profiles: Channel-shaped FRP profiles are used for applications that require a combination of strength and versatility. They find applications in cable trays, equipment supports, and framing systems. 5. Angle profiles: FRP angle profiles are commonly used as reinforcements or supports in construction and industrial settings. They provide stability and structural integrity to various components. 6. Custom profiles: Apart from the standard shapes mentioned above, FRP pultrusion profiles can also be customized to meet specific requirements. Manufacturers can create profiles with unique shapes and sizes to suit the needs of different applications. It is important to note that the availability of shapes and sizes may vary among manufacturers. Therefore, it is advisable to consult with suppliers or manufacturers to determine the specific range of FRP pultrusion profiles they offer.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the production of electrical cabinets. FRP pultrusion profiles provide excellent electrical insulation properties, high strength-to-weight ratio, and resistance to corrosion, making them suitable for use in electrical cabinets where electrical safety and durability are essential.

- Q: Are FRP pultrusion profiles UV-resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because they are made by combining reinforcing fibers, like glass or carbon, with a polymer matrix, such as polyester or vinyl ester. These materials naturally resist UV radiation, allowing FRP pultrusion profiles to endure long exposure to sunlight without significant deterioration or loss of mechanical properties. However, it's important to note that the UV resistance of FRP pultrusion profiles can vary based on the polymer matrix's type and quality used in their manufacturing. Thus, it is recommended to consult the manufacturer or supplier for detailed information regarding the UV resistance of specific FRP pultrusion profiles.

- Q: How do FRP pultrusion profiles perform in high-traffic areas?

- FRP pultrusion profiles are an excellent choice for high-traffic areas due to their exceptional performance characteristics. These profiles are made of reinforced fiberglass and resin, resulting in a highly durable material that can withstand heavy loads and constant foot traffic. One of the key advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lightweight yet incredibly strong, allowing them to handle heavy loads without sacrificing their structural integrity. Additionally, their non-corrosive nature makes them ideal for areas with high foot traffic, where exposure to moisture, chemicals, and other corrosive elements is common. FRP pultrusion profiles also possess excellent resistance to wear and abrasion. This means that even in high-traffic areas, where constant footfalls and movement can cause conventional materials to deteriorate quickly, FRP profiles remain unaffected, maintaining their original appearance and functionality for an extended period. Furthermore, these profiles are highly resistant to UV radiation, which means they do not degrade or fade when exposed to sunlight. This is particularly important for high-traffic areas that are outdoors or have large windows, as the profiles will maintain their strength and aesthetics even under constant exposure to the sun. In terms of maintenance, FRP pultrusion profiles require minimal upkeep. They do not require regular painting or sealing, as their color and finish are built into the material itself. This significantly reduces maintenance costs and efforts, making them a cost-effective choice for high-traffic areas. Overall, FRP pultrusion profiles are an excellent option for high-traffic areas due to their exceptional strength, durability, resistance to wear and abrasion, non-corrosive properties, UV resistance, and low maintenance requirements. Their ability to withstand heavy loads and constant foot traffic ensures their long-lasting performance, making them a reliable choice for any high-traffic environment.

- Q: Can FRP pultrusion profiles be used in transportation infrastructure, such as bridges or platforms?

- Transportation infrastructure, including bridges and platforms, can effectively utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous properties that render them suitable for such applications. To begin with, FRP pultrusion profiles are renowned for their exceptional strength-to-weight ratio. This implies that they provide considerable structural strength while remaining lightweight. This quality is particularly valuable in transportation infrastructure, where weight reduction is crucial for enhancing energy efficiency and minimizing construction expenses. Moreover, FRP pultrusion profiles exhibit a high level of corrosion resistance. Unlike traditional construction materials like steel, FRP does not corrode when exposed to moisture or chemicals. This corrosion resistance makes FRP pultrusion profiles perfect for transportation infrastructure situated in harsh environmental conditions, such as bridges located in coastal areas or platforms susceptible to chemical spills. Additionally, FRP pultrusion profiles offer outstanding durability and longevity. They possess an extended service life and can withstand heavy loads, vibrations, and impacts. This ensures their suitability for high-traffic areas, guaranteeing that transportation infrastructure remains structurally sound and safe for an extended period. Lastly, FRP pultrusion profiles provide excellent design flexibility. They can be manufactured in various shapes and sizes, enabling customized solutions that meet the specific requirements of transportation infrastructure projects. They can be easily molded into intricate geometries, facilitating efficient construction and reducing the need for additional components. In conclusion, the properties of FRP pultrusion profiles make them highly suitable for utilization in transportation infrastructure, such as bridges or platforms. Their exceptional strength-to-weight ratio, corrosion resistance, durability, and design flexibility make them a reliable and cost-effective choice for constructing safe and efficient transportation systems.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP pultrusion profiles are highly resistant to moisture absorption. The inherent properties of the fiberglass and resin used in pultrusion manufacturing make the profiles highly durable and impervious to moisture, ensuring long-term performance and minimal structural damage.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP (Fiber Reinforced Polymer) pultrusion profiles possess several desirable mechanical properties that make them a popular choice in various industries. Some of the key mechanical properties of FRP pultrusion profiles include: 1. High Strength: FRP pultrusion profiles exhibit exceptional tensile and flexural strength, making them suitable for applications requiring load-bearing capabilities. The reinforcing fibers, such as carbon, glass, or aramid, provide the profiles with superior strength-to-weight ratios compared to traditional materials like steel or aluminum. 2. Lightweight: FRP pultrusion profiles are significantly lighter than metals, resulting in reduced transportation and installation costs. The low weight also makes them easier to handle and manipulate during construction or manufacturing processes. 3. Corrosion Resistance: Unlike metals, FRP pultrusion profiles are inherently corrosion-resistant. They do not rust, corrode, or degrade when exposed to harsh environments, including moisture, chemicals, or UV radiation. This property makes them ideal for applications in marine, chemical, and infrastructure industries. 4. Dimensional Stability: FRP pultrusion profiles offer excellent dimensional stability, meaning they retain their shape and size even under extreme temperature variations. They have minimal thermal expansion and contraction rates, ensuring long-term structural integrity. 5. Electrical Non-Conductivity: FRP profiles are non-conductive and possess excellent electrical insulation properties. This property is crucial in applications where electrical conductivity must be avoided, such as in electrical enclosures or infrastructure near power lines. 6. Design Flexibility: FRP pultrusion profiles can be manufactured in various complex shapes and sizes, allowing for customized designs to meet specific application requirements. They can be easily molded or formed during the manufacturing process, making them adaptable to diverse project needs. 7. Impact Resistance: FRP pultrusion profiles exhibit good impact resistance, absorbing and dispersing energy when subjected to mechanical loads. This property ensures durability and structural integrity, making them suitable for applications prone to impact or dynamic loading, such as construction, transportation, or sporting equipment. Overall, the mechanical properties of FRP pultrusion profiles make them an attractive alternative to traditional materials in a wide range of industries, offering strength, durability, and corrosion resistance while being lightweight and easy to work with.

Send your message to us

FRP Pultrusion Profiles Gritted FRP Grating-1/12 Inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords