Grass PVC Conveyor Belt Rough Top PVC Conveyor Belt used in Beer Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grass PVC Conveyor Belt Rough Top PVC Conveyor Belt used in Beer Industry

PVC Conveyor Belt

PVC Conveyor Belt is made with low-stretch 100% polyester and woven into a strong interwoven carcass. Available in a variety of strengths, colors, compounds, and cover styles to meet your exact requirements. Our belts are suitable for light and medium applications in which a wide variety of packages, products and materials need to be conveyed. After nearly ten years development, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

1). Food quality types to FDA standards

2).Anti-static and non-conductive

3). Resistance to abrasion, oils, fats and chemicals

4). High transverse rigidity and dimensional stability

5).Surfaces with low, medium or high coefficient of friction

6). Low noise

7). Working temperature ranges from -10 to 80Deg.C

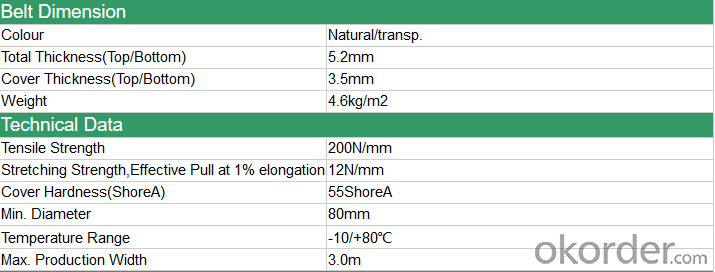

PVC Conveyor Belt Specification

PVC Conveyor Belt Application

Logistics industry

Paper and print industry

Packaging machines

Labelling machines

Cardboard industry

Cable and wire industry

Electronics industry

Wood industry

Tobacco industry

Food industry

Metal industry

Our Service

1)Welcome your sample to custom.

2)Samples are available.

3)Extra belt surface profiles including the guides, the sidewalls, cleats, steel buckles, all can bewelded to the belts at our facilities.

4)Joints making --- Flexproof, Thermofix, Fast-joining, Steel buckles.

5)We provide OEM service, ODM service and OBM service.

6)Small and trial orders are acceptable.

PVC Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the applications of rubber airbags in the automotive field?

- China's expanding automotive market offers great opportunities and development opportunities for specialty rubber and further extends its application. At the same time, the performance and environmental protection requirements of automobile rubber products have been improved. Automobile industry drives rubber products market.

- Q: Rubber and metal have to be sealed before they are too strong

- The percentage difference between the first compression compression = original section diameter minus the trench size divided by the original O ring diameter O-ring compression is mainly depends on the material hardness and O-ring, O-ring if the hardness is 70 degrees, then the O-ring compression is equal to 20%. Of course, the lower the hardness of the O-ring, O-ring compression is greater, mainly used for low pressure places. Then the O-ring hardness increases the amount of compression of the O-ring is smaller, mainly used for high pressure, pressure resistance, resistance of small environment. And so on, the amount of compression can be any hardness O-ring you need.

- Q: What is the pressure on rubber products during vulcanization?

- It can be seen that the vulcanization time can be shortened by increasing the sulfuration temperature. The process of high temperature vulcanization is injection vulcanization and electric heating flat vulcanization. Both of them can be cured at 160 DEG C or even higher. In recent years, the industry has also adopted the trend of high temperature vulcanization. In addition, the continuous vulcanization process using eutectic liquid as heating medium has also begun to use high temperature vulcanization. In the rubber injection molding process, because the rubber material has passed the preheating and plasticizing of the screw, higher vulcanization temperature (such as 175~183 DEG C) can be adopted, but the reversion or sulfuration of rubber is less affected. For example, for three yuan ethylene propylene rubber, when set 160 degrees for molding, the positive curing time is 60min, if it is changed to 200 degrees noteThe time of vulcanization is only 4min. With the use of general-purpose rubber to make small products, the vulcanization time can be l-2mm.

- Q: What are the rubber parts for the car?

- Filter rubber parts, cloth (diaphragm), injection pump sealing ring, car frame sealing strip, door seal..... There are many, the car inside the big, small, a lot of rubber products. Watch more and you'll see.

- Q: Does it work in a rubber factory that causes skin irritations?

- Working in a rubber factory can cause skin irritations. Rubber itself does not cause skin allergies. It may be caused by the vulcanization of rubber.

- Q: What is rubber damping material?

- Butyl rubber, butyl bromide and butyl chloride are the main ones!! Need to design, sell rubber products, can find me!

- Q: How to identify the tire rubber is raw or cooked

- All use glue tire manufacturing, rubber is the parent material of rubber products, rarely used directly.

- Q: How do you remove the black dirt on the rubber?

- You should be rubber silicone, most of all is blackTry rubbing it with diluted alcohol.

- Q: Will rubber products fade?

- Rubber products will fade, is a rubber aging process, mainly due to external factors, temperature changes, the use of time, light, chemicals, external force and so on.

- Q: What is the rubber composition and function of the airplane tyres?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and flexibility, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the tear resistance of the cross, wet skid resistance is not good. Isoprene rubber is the abbreviation of polyisoprene rubber. It is produced by solution polymerization. Isoprene rubber, like natural rubber, has good elasticity and wear resistance, excellent heat resistance and good chemical stability. Isoprene rubber (not before processing) strength was significantly lower than that of natural rubber, but the quality uniformity, processing performance is better than natural rubber. Isoprene rubber can be used instead of natural rubber to make heavy-duty and off-road tires, and can also be used to produce all kinds of rubber products.

Send your message to us

Grass PVC Conveyor Belt Rough Top PVC Conveyor Belt used in Beer Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords