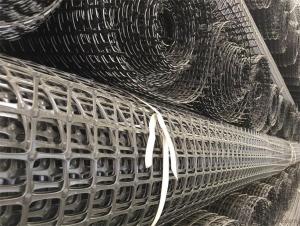

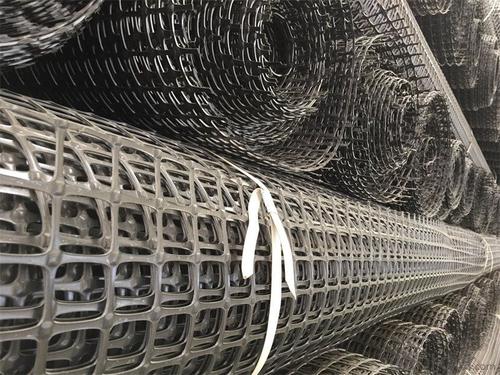

Geogrids for Access Routes:Lightweight Grass Protection for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.

WEIGHT

300G/SQM

500G/SQM

ELONGATION AT BREAK

3%

TENSILE STRENGTH IN KNOT

5KN/M

10KN/M

WIDTH:

1--6M

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are generally resistant to hydrostatic pressure.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement to the soil structure. They are designed to distribute the forces exerted by the soil and help prevent erosion and slope failure. Geogrids act as a stabilizing mechanism by increasing the strength of the levee, reducing the potential for settlement, and enhancing its overall stability.

- Q: Can geogrids be used in retaining walls for industrial facilities?

- Yes, geogrids can be used in retaining walls for industrial facilities. Geogrids are commonly used in the construction of retaining walls to enhance stability, improve soil reinforcement, and provide long-term durability. Industrial facilities often require sturdy and reliable retaining walls to support heavy loads and ensure the safety of the structure. Geogrids offer an effective solution by distributing the forces exerted on the retaining wall and preventing soil erosion, thereby improving the overall performance and longevity of the wall in industrial settings.

- Q: 0.3m drainage geogrid

- Of course, there are many other manufacturers

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing stability to soil and reducing the need for excessive excavation and material usage. They allow for the use of locally available and low-quality soil, eliminating the need to import expensive and environmentally damaging materials. This reduces the amount of waste generated during construction and helps in preserving natural resources.

- Q: How do geogrids help in reducing settlement of foundations?

- Geogrids help in reducing settlement of foundations by providing additional reinforcement and stabilization to the soil. They are placed within the soil layers to distribute the load more evenly, increase the bearing capacity, and reduce the potential for settlement.

- Q: What are the factors that affect the cost-effectiveness of geogrid-reinforced structures?

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of geogrid used can significantly impact the overall cost. Higher quality geogrids may be more expensive but can provide better reinforcement, leading to longer-lasting and more cost-effective structures. Additionally, the design and engineering of the structure play a crucial role. Properly designed structures that consider factors such as soil conditions, loading requirements, and anticipated lifespan can ensure optimal performance and cost-effectiveness. The construction process and techniques employed also influence the cost-effectiveness. Efficient construction methods, skilled labor, and effective project management can minimize costs and maximize the durability and longevity of the geogrid-reinforced structure. Lastly, the maintenance and monitoring of the structure are essential. Regular inspections and timely repairs, if needed, can prevent costly damages and extend the lifespan of the structure, ultimately enhancing its cost-effectiveness.

- Q: Are geogrids suitable for slope stabilization?

- Yes, geogrids are suitable for slope stabilization. Geogrids are commonly used in civil engineering projects for reinforcing slopes and retaining walls. They provide stability by distributing the load and preventing soil erosion, thus effectively stabilizing slopes and preventing landslides.

- Q: Are geogrids suitable for use in reinforced embankments?

- Yes, geogrids are suitable for use in reinforced embankments. Geogrids provide soil stabilization and enhance the strength of the embankment by distributing loads and reducing lateral movement. They have been widely used in various civil engineering projects for reinforcing slopes and retaining walls, making them a reliable and effective solution for reinforced embankments.

- Q: How to do this in the geogrid in the retaining wall? Is there any remedy?

- High tensile strength and low elongation glass fiber geogrid is a glass fiber as raw material, has a high resistance to deformation, the elongation rate is less than 3%.

Send your message to us

Geogrids for Access Routes:Lightweight Grass Protection for Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords