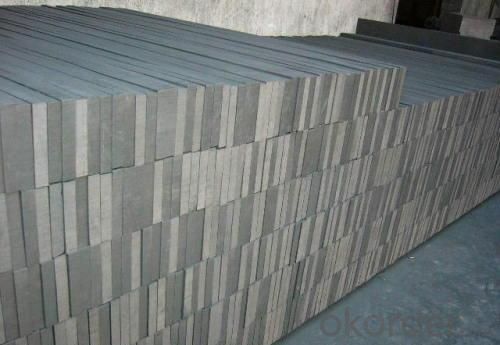

Graphite Plate/CNBM Wholesale Carbon Graphite Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | standard export wooden package or according to customers' request |

| Delivery Detail: | 15-30days after receiving your deposit |

Product Description

Graphite plate is made form the domestic petroleum coke and widely used in the metallurgy, machinery, electronics and chemical industry, etc. The graphite plate include molded, extruded, vibrated and isostatic. Our main and most preponderant graphite plate is molded formed. Our products own the following characteristics: low electricr esistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy and so on.

Usage

They have been used extensively in industries like solar, foundry, chemicals, electronics, ferrous metals, high-temp, heat conduction, metallurgy, lubrication, anti-corrosion .etc

1. Refractory material: widely used in the metallurgical industry.

2. Conducting material: In the electronics industry, widely used for graphite electrode, brush,, etc

3. Wear-resisting material and lubricant: Use graphite as wear-resisting and lubrication materials, can be 100m/s speed sliding in - 200 ~ 2000 °C temperature range , no or less lubricanting oil.

4. Sealing material: it can be as sealing ring in the equipment, such as centrifugal pump, hydraulic turbine ,etc.

5. Anticorrosion material: Widely used in petroleum, chemical, hydrometallurgy departments.

6. Insulation, high temperature resistant, radiation protection materials

7.Molds: hot pressing molds, static casting molds, centrifugal casting molds, pressure casting molds, fused refractory molds, etc.

8. Furnace parts: resistance heating elements, induction susceptors, structural elements and charging plates, furnace linings, heat shields and covers for pulling monocrystalline silicon or optical fibers, etc.

9. Anodes for the electrolysis of metals. As graphite elecerode plate and graphite anode plate .

10.. Parts for heat exchangers.

11. Mahince to Crucibles for melting and reduction.

Physical and chemical index

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 0.8 | 0.8 |

Density | g/cm3 | ≥1.70 | 1.73 |

Resistance | ohm | ≤8.5 | 7.5 |

Bending Strength | MPa | ≥10.0 | 11.0 |

Compressive strength | MPa | ≥24.0 | 17.0 |

Thermal conductivity | W(m.k) | ≤120 | 150 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.2 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 0.8 | 0.8 |

Density | g/cm3 | ≥1.73 | 1.76 |

Resistance | ohm | ≤8.0 | 7.0 |

Bending Strength | MPa | ≥12.0 | 12.5 |

Compressive strength | MPa | ≥31.0 | 34.0 |

Thermal conductivity | W(m.k) | ≤130 | 160 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.1 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 2 | 2 |

Density | g/cm3 | ≥1.58 | 1.60 |

Resistance | ohm | ≤11.5 | 10.5 |

Bending Strength | MPa | ≥6.0 | 6.5 |

Compressive strength | MPa | ≥18.0 | 18.5 |

Modulus of elasticity | GPa | ≤9.3 | 7.5 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.4 |

Ash Content | % | ≤0.3 | 0.09 |

Item | Unit | Guarantee Value | Typical Value |

Grain size | mm | 2 | 2 |

Density | g/cm3 | ≥1.70 | 1.75 |

Resistance | ohm | ≤8.5 | 7.5 |

Bending Strength | MPa | ≥9.0 | 9.5 |

Compressive strength | MPa | ≥30.0 | 31.0 |

Modulus of elasticity | GPa | ≤12.0 | 9.5 |

C.T.E(100-600)℃ | 10-6/℃ | ≤2.5 | 2.3 |

Ash Content | % | ≤0.3 | 0.09 |

Picture

- Q: What can light hydrocarbon carbon five be packed with?

- The stove is rated 1000 + 200Pa, outdoor transmission and distribution pipe network according to the number of users determine the diameter of the smallest diameter, 108mm diameter, maximum diameter 325mm, are made of seamless steel pipe or special gas PE pipe, outdoor pipe network by welding or hot melt connection method, the indoor pipeline for galvanized pipe, mainly adopts threaded connection. The design and construction are the same as that of the natural gas pipeline network. If the natural gas is replaced, it can be butted with the natural gas pipe mouth, and the indoor and outdoor pipe network need not make any change.

- Q: Which is better, 13 and 14 carbon breath tests?

- According to your case, carbon 14 is cheaper than 13, and the accuracy is the same

- Q: How is carbon used in the production of carbon nanomaterials?

- Carbon is used as the raw material for the production of carbon nanomaterials. Different forms of carbon, such as graphite or carbon black, are transformed through various processes like chemical vapor deposition or arc discharge to create carbon nanotubes or graphene.

- Q: How is carbon used in the production of filters?

- Due to its unique properties, carbon finds common usage in filter production. One of the primary applications of carbon in filters is its capacity to adsorb impurities and contaminants, attracting and retaining them. This is attributed to carbon's extensive surface area and multitude of minute pores, enabling it to effectively capture and eliminate particles, chemicals, and odors from substances like air, water, and more. In air filters, carbon is frequently combined with other materials, such as activated charcoal, to form activated carbon filters. These filters are utilized to eradicate air pollutants, allergens, and odors. The activated carbon adsorbs the contaminants, entrapping them within its porous structure and ultimately enhancing the overall air quality. In water filters, carbon can be employed in diverse forms, like granular activated carbon (GAC) or carbon block filters. GAC filters are widely utilized in household water filtration systems and are adept at eliminating chlorine, volatile organic compounds (VOCs), pesticides, and other chemicals. Conversely, carbon block filters are produced by compressing activated carbon into a solid block, thus providing a greater surface area and superior filtration efficiency. Apart from air and water filters, carbon is also utilized in various other filter types, such as those utilized in industrial processes, gas masks, and respirators. The versatility of carbon in filtering applications stems from its capability to adsorb a broad range of contaminants and its high adsorption capacity. Its inclusion in filters aids in enhancing the quality and safety of the substances undergoing filtration, rendering it an indispensable material in numerous filtration processes.

- Q: What are the impacts of carbon emissions on human health in developing countries?

- Developing countries are significantly affected by carbon emissions, which have considerable consequences for human health. The burning of fossil fuels and deforestation are the primary sources of these emissions, which contribute to the deterioration of air quality and give rise to a variety of health problems. Respiratory diseases are among the most immediate and visible impacts caused by high levels of carbon emissions. These emissions release harmful pollutants such as particulate matter and nitrogen dioxide, which can irritate the respiratory system and worsen existing conditions like asthma and bronchitis. In developing countries where access to healthcare may be limited, these respiratory diseases can be particularly harmful and lead to higher mortality rates. Furthermore, climate change, driven by carbon emissions, indirectly affects human health. Rising temperatures and shifting weather patterns can facilitate the spread of diseases transmitted by vectors, such as malaria and dengue fever. Developing countries often lack the necessary infrastructure and resources to effectively combat these diseases, resulting in increased rates of infection and mortality. Additionally, carbon emissions contribute to the formation of ground-level ozone, a harmful air pollutant. Exposure to high levels of ozone can cause respiratory problems, cardiovascular issues, and even premature death. Developing countries, with their limited access to healthcare and vulnerability to extreme weather events, may experience higher rates of illness and mortality due to ozone exposure. Moreover, carbon emissions contribute to the acidification of oceans, which negatively impacts marine ecosystems. This, in turn, affects the availability and quality of seafood, which is a vital source of nutrition for many people in developing countries. Impaired access to nutritious food can lead to malnutrition and various health issues, especially among vulnerable populations such as children and pregnant women. In conclusion, the impacts of carbon emissions on human health in developing countries are severe. The release of pollutants from burning fossil fuels and deforestation leads to respiratory diseases, the spread of vector-borne illnesses, ozone-related health problems, and nutritional deficiencies. These health impacts underscore the importance of prioritizing sustainable development and transitioning to clean energy sources in developing countries. Additionally, international cooperation is crucial in addressing this global issue.

- Q: What are the different types of carbon-based polymers?

- There are several different types of carbon-based polymers, including polyethylene, polypropylene, polystyrene, polyvinyl chloride (PVC), and polyurethane.

- Q: Carbon content of fly ash and fly ash roasted vector what is the relationship?

- The amount of burning loss of fly ash is the index that indicates the unburned organic matter in coal ash, including the number of carbon particles. The greater the burn loss, the more carbon is burnt. The presence of unburned carbon has a great negative impact on the quality of fly ash.

- Q: How does carbon affect the properties of steel?

- Carbon affects the properties of steel by increasing its hardness, strength, and overall durability. The presence of carbon allows for the formation of iron carbides, which strengthen the steel's crystal lattice structure. The higher the carbon content, the harder and stronger the steel becomes. However, excessive carbon can make the steel brittle, reducing its impact resistance.

- Q: How does carbon dioxide affect the formation of smog?

- Carbon dioxide does not directly contribute to the formation of smog. However, it indirectly influences smog formation by contributing to climate change, which can lead to increased temperatures and the formation of ground-level ozone, a key component of smog.

- Q: Learn photography for nearly half a year, has always wanted to buy a tripod, want to buy carbon fiber tripod, what brand is better? The machine is D700+24-70About 3000 is too expensive ~ consider 1000 more just fine. Wage earners!

- The three tripod has such a word: buy third tripod to know the first two are white bought!This sentence is a lot of friends with real money summed up, and hope to see!The three tripod is the most important, safe and reliable, and then the price, can not guarantee the safety of equipment, the price is cheaper and useless.The more than 1000 budget recommendations for the selection of source or berno, quality guaranteed, price is also good. If not on the cannon, not in harsh environment, the maximum diameter of 25mm, 4 section can also (cheap).Finally: carbon fiber hundreds of three tripod is not necessarily not, but never heard of this three foot will drop the camera, my answer can only represent personal views, for a reference.

Send your message to us

Graphite Plate/CNBM Wholesale Carbon Graphite Plates

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords