350mm Graphite Electrode for Producing Alloy Steels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode for Proudcing Alloy Steels

Composite of Graphite Electrode for Proudcing Alloy Steels

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm.

Applications of Graphite Electrode for Proudcing Alloy Steels:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Advantages of Graphite Electrode for Proudcing Alloy Steels:

low electric resistance

good electric and thermal conductivity

high oxidation resistance

high mechanical strength

high machining accuracy

greater resistance to thermal and mechanical shock

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

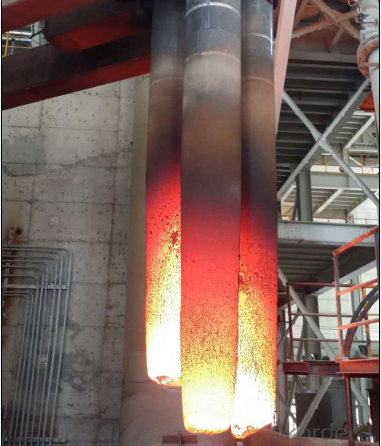

Graphite Electrode for Proudcing Alloy Steels Images

Specifications of Graphite Electrode for Proudcing Alloy Steels:

Item | Unit | Regular-power | Impregnated | ||||||

φ75- | φ150- | φ250- | φ350- | φ75- | φ250- | φ400- | |||

130 | 225 | 300 | 500 | 200 | 350 | 500 | |||

Specific Resistance (≤) | E | μ Ω·m | 8.5 | 9 | 9 | 9 | 8 | 8 | 8 |

N | 8 | 8 | 8 | 8 | 7.5 | 7.5 | 7.5 | ||

Bending Strength (≥) | E | MPa | 9.8 | 9.8 | 7.8 | 6.4 | 10 | 9 | 8 |

N | 13 | 13 | 13 | 13 | 15 | 15 | 15 | ||

Elastic Modulus (≤) | E | GPa | 9.3 | 9.3 | 9.3 | 9.3 | 12 | 12 | 12 |

N | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||

Bulk Density (≥) | E | g/cm3 | 1.58 | 1.52 | 1.52 | 1.52 | 1.58 | 1.58 | 1.58 |

N | 1.63 | 1.63 | 1.68 | 1.68 | 1.68 | 1.68 | 1.68 | ||

C.T.E.(≤) | E | 10-6/°C | 2.9 | 2.9 | 2.9 | 2.9 | 2.7 | 2.7 | 2.7 |

(100-600°C) | |||||||||

| N | 2.7 | 2.7 | 2.8 | 2.8 | 2.5 | 2.5 | 2.5 | |

Ash(≤) |

| % | 0.5 | 0.5 | 0.5 | 0.5 | 0.3 | 0.3 | 0.3 |

FAQ of Graphite Electrode for Proudcing Alloy Steels

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: Why graphite can be used as conductive material?

- Graphite used in the electrical industry requires a high degree of particle size and grade. Such as alkaline batteries and some special electric carbon products, requiring graphite particle size control within the scope of the project, grade above, harmful impurities are required in the following. The graphite used in a picture tube for television is required below. As a wear-resistant and lubricating material, graphite is often used as a lubricant in the mechanical industry.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode has good electrical and chemical stability. It has high mechanical strength, low impurity content and good vibration resistance at high temperature. It is a good conductor of heat and electricity. Qingdao Chenyang graphite graphite electrode quality is good, they are a direct manufacturer of graphite electrode. Hope to be of some help to you.

- Q: Will the brush grease not short-circuit the commutator?

- The brush of motor is usually made of pure graphite electrode, electrochemical graphite electrode and metal fossil ink electrode material. Because it contains graphite, it has conductive effect on the one hand

- Q: In EDM, the electrodes are made of graphite and copper. Please tell us the difference between them

- For operators, copper is certainly better, graphite will have dust, the human body has serious harm

- Q: Can Naiduo high temperature graphite

- Graphite cut gasket is from pure graphite plate drilling or cutting and it has good corrosion resistance, high / low temperature, compression elasticity and high strength good, complex geometric gasket circular is widely used in all kinds of pipes, valves, pumps, pressure vessels, heat exchanger, and condenser generator, air compressor, exhaust pipe, refrigerator etc..

- Q: How should carbon deposits be treated?

- At certain temperature, can make alloy and carbon can react in the engine surface coated with a layer of graphene film, graphene nano particles can fill the pores, wear scratches, on the friction surface repair function.

- Q: How can the graphite powder be processed into high quality carburizing agent? Thank you

- So that impurities on the high, so basically can not be processed into so-called quality, and can leave a contact, discuss each other

- Q: Graphitized coke, graphite, broken, mixed up, how to export?

- The graphite powder is soft, black and gray, greasy and polluting paper. Hardness is 1~2, along the vertical direction with the increase of impurities, its hardness can be increased to 3~5. The specific gravity is 1.9 ~ 2.3. Under isolated oxygen conditions, the melting point is above 3000 degrees Celsius and is one of the most refractory minerals. At room temperature, the chemical properties of stone toner are relatively stable, insoluble in water, dilute acid, dilute alkali and organic solvents. The material has high temperature resistance and conductivity, and can be used as refractory materials, conductive materials, wear-resistant and lubricating materials.

- Q: How do graphitized electrodes differentiate between high power and low power?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages.

- Q: Graphite is made of high-strength graphite, it is a kind of graphite grade specification.

- Graphite rod refers to graphite rod without processing. A graphite electrode refers to a finished product.

Send your message to us

350mm Graphite Electrode for Producing Alloy Steels

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches