Hp 400mm Graphite Electrodes - Gextruded Graphite Rod/Hpraphite Electrode/Synthetic Graphite Rod Blank Dia 90mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to 700mm. Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

Used in EAF and LF for steel making, as well as in electric smelting furnace for producing industrial silicon, phosphorus, etc.

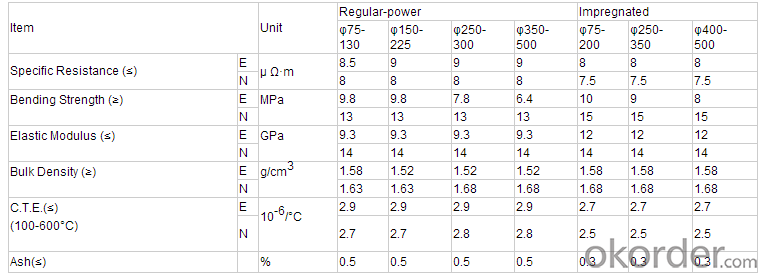

Graphite Electrodes Specifications

1.Good electrical conductivity

2.High resistance to thermal shock

3.High mechanical strength

Grades:RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Why use platinum ferroalloy instead of iron as electrode?

- Silica (Silica) is widely used in paint, ink, plastic, rubber and cosmetics, are often added to increase the performance of silica, such as oil absorption, extinction, strengthen the mechanical... Etc., and can reduce the cost of...

- Q: What are the skills of hardfacing process for wear-resistant alloy powder blocks?

- The hardfacing of wear-resistant alloy powder block is mostly made by carbon arc surfacing. General selection of graphite or carbon arc surfacing carbon rod and plate electrodes, which has good conductivity, high melting point;

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- If it is molten, it can be made out of silverFor solution, only AgNO3+H2O== electrolysis ==Ag+HNO3+O2 is analyzedWhen the HNO3 concentration is enough, it will continue to react with Ag.... So you can't get Ag elements.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- Carbon deposition can cause insufficient combustion of gasoline and cause engine chattering.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Graphite electrode has better machining stability and high production efficiency. It is easy to be used as EDM electrode material in EDM when it is processed with long pulse width and high current.

- Q: What are the losses in graphite electrode?

- In what environment is the loss, friction, or in the case of high temperature, high temperature will be oxidized, and if in the case of friction, you can first use more wear-resistant graphite material. So please ask this question clearly, and then answer you, thank you.

- Q: Electrolysis of CuCl2 solutions with graphite electrodes

- After energization, electrolysis occurs, not ionizationIonization does not require energization, and can occur in aqueous or molten state.

- Q: How do graphitized electrodes differentiate between high power and low power?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages.

- Q: What are pyrolytic graphite electrodes used for?

- Discharge consumption; because the spark oil also contains C atoms in the discharge process, high temperature oil spark decomposition of C atom, and form a protective film on the surface of the graphite electrode, graphite electrode loss compensation.

- Q: How about graphite electrode high-temperature oxidation resistant coating?

- Heat resistant coating is generally able to withstand 300 degrees below the temperature, commonly used aluminum heat-resistant paint, high temperature resistance can withstand higher temperatures, such as 800 degrees or more, commonly used silicone heat-resistant paint

Send your message to us

Hp 400mm Graphite Electrodes - Gextruded Graphite Rod/Hpraphite Electrode/Synthetic Graphite Rod Blank Dia 90mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords