Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Details of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Name | SAE1045 Carbon Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Grades Comparison

GB | ASTM | JIS | DIN | BS | NF |

45# | 1045 | S45C | C45 | IC45 08047 | C45 |

Chemical Composition

C | Si | Mn | Cr | P/S | Cr |

0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | ≤0.35 | 0.3-0.5 |

Sizes information

Sizes detalis | diameter | 16-320mm |

length | 3-12m(canbe customerized) | |

Sizes tolerance (max) | length | +/-100mm |

diameter | +/-2mm | |

Straightness | 3mm/m |

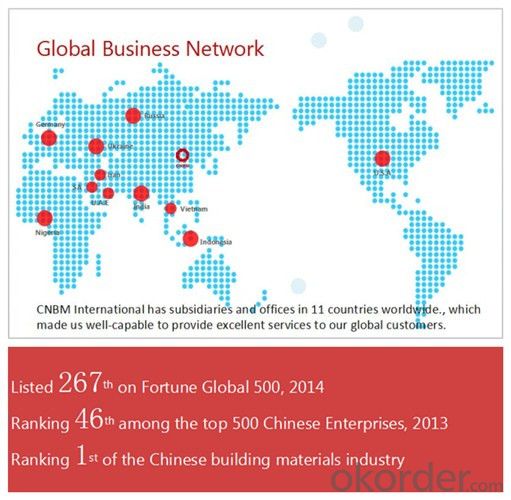

CNBM Introduction of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does stainless steel contribute to the automotive industry?

- Stainless steel contributes to the automotive industry by providing strength, durability, and corrosion resistance in various automotive components such as exhaust systems, body panels, and engine parts. Its ability to withstand extreme temperatures and harsh conditions make it a preferred material for manufacturing high-performance vehicles. Additionally, stainless steel's aesthetic appeal and low maintenance requirements make it suitable for decorative purposes in car interiors and exteriors.

- Q: How does special steel contribute to the power generation aftermarket industry?

- Special steel plays a crucial role in the power generation aftermarket industry by providing high-quality and durable materials that are essential for the construction and maintenance of power generation equipment. Special steels, such as stainless steel and alloy steel, possess unique characteristics that make them well-suited for the demanding conditions and requirements of the power generation sector. One of the key contributions of special steel to the power generation aftermarket industry is its exceptional resistance to corrosion and oxidation. Power generation equipment, such as gas turbines and steam generators, operate in harsh environments where they are subjected to extreme temperatures, pressure, and exposure to various chemical elements. Special steel's corrosion resistance ensures that the equipment can withstand these challenging conditions, thereby minimizing the risk of failure and extending the lifespan of the equipment. Additionally, special steel offers excellent strength and toughness, allowing power generation equipment to withstand high mechanical stress and fatigue. The power generation industry relies on turbines, boilers, and other heavy machinery that are subjected to continuous operation and significant loads. Special steel's high strength and durability enable these components to endure the demanding conditions and effectively handle the power generation process, ensuring safe and reliable operation. Another significant contribution of special steel to the power generation aftermarket industry is its ability to maintain dimensional stability under extreme temperatures. Power generation equipment often operates at high temperatures, and special steel's thermal stability prevents distortion and deformation, ensuring that the equipment retains its shape and functionality over time. Moreover, special steel's versatility allows for the production of various components and parts, customized to meet the specific requirements of power generation equipment. Whether it is turbine blades, boiler tubes, or heat exchangers, special steel can be tailored to provide the desired mechanical properties, corrosion resistance, and thermal stability needed for each application. In summary, special steel is an indispensable material in the power generation aftermarket industry. Its corrosion resistance, strength, toughness, thermal stability, and versatility make it an ideal choice for constructing and maintaining power generation equipment. By providing reliable and durable materials, special steel contributes to the efficiency, safety, and longevity of power generation systems, ensuring the continuous supply of electricity to meet the growing demands of our modern world.

- Q: How is special steel produced?

- Special steel is typically produced through a combination of several processes, including melting, refining, casting, and heat treatment. It involves carefully selecting and blending various alloying elements to achieve desired chemical and mechanical properties. These elements are added to molten steel, which is then refined to remove impurities. The refined steel is then cast into various shapes and forms, such as bars, sheets, or tubes. Finally, the steel undergoes heat treatment processes like tempering or quenching to further enhance its strength and other properties.

- Q: How does special steel contribute to the aerospace material recyclability?

- Special steel contributes to the aerospace material recyclability by offering high durability and strength, making it a preferred material for various aircraft components. Its recyclability is enhanced through processes such as melting and reformation, allowing the steel to be reused in new applications. This reduces the need for new steel production, conserves resources, and minimizes waste generation in the aerospace industry.

- Q: How does special steel perform in magnetic applications?

- Special steel performs well in magnetic applications due to its high magnetic permeability and low electrical conductivity. This allows it to efficiently conduct and concentrate magnetic fields, making it ideal for various magnetic devices and applications such as transformers, motors, generators, and magnetic sensors. Additionally, special steel can exhibit excellent magnetic properties such as high saturation magnetization and low coercivity, making it capable of generating strong magnetic fields and maintaining magnetization even in challenging conditions.

- Q: How does the heat treatment process affect the properties of special steel?

- The heat treatment process can significantly affect the properties of special steel. It involves heating the steel to a specific temperature and then cooling it at a controlled rate to alter its microstructure. This process can change the steel's hardness, strength, toughness, and even its resistance to corrosion. By manipulating the heat treatment parameters, such as temperature, time, and cooling rate, manufacturers can tailor the properties of special steel to meet specific requirements for different applications.

- Q: Can special steel be used for aerospace engine components?

- Yes, special steel can be used for aerospace engine components. Special steel is often preferred for its exceptional strength, heat resistance, and durability, making it suitable for the demanding conditions and high temperatures experienced in aerospace engines. Additionally, special steel alloys can be tailored to specific requirements, enabling engineers to optimize performance and enhance overall efficiency in aerospace applications.

- Q: What are the different inspection methods used for special steel?

- There are several inspection methods used for special steel, including visual inspection, magnetic particle inspection, ultrasonic inspection, and dye penetrant inspection. Visual inspection involves examining the steel for any surface defects or irregularities. Magnetic particle inspection uses magnetic fields and iron particles to detect any cracks or defects in the steel. Ultrasonic inspection involves sending high-frequency sound waves through the steel to identify any internal flaws or defects. Dye penetrant inspection involves applying a colored liquid to the steel's surface, which seeps into any cracks or defects, revealing their presence. These methods help ensure the quality and integrity of special steel products.

- Q: What are the main advantages of using special steel in the power generation industry?

- The main advantages of using special steel in the power generation industry are its exceptional strength, resistance to corrosion and high-temperature capabilities. These properties make special steel highly suitable for critical components like turbines, boilers, and generators, ensuring their durability and reliability in harsh operating conditions. Additionally, special steel's ability to withstand extreme pressure and stress enhances the overall safety and efficiency of power plants.

- Q: How does special steel contribute to the strength of structures?

- Special steel contributes to the strength of structures by providing enhanced mechanical properties such as higher tensile strength, improved toughness, and increased resistance to corrosion. These properties allow special steel to bear heavier loads, withstand extreme weather conditions, and maintain structural integrity over time, making it a crucial material choice for constructing durable and reliable buildings, bridges, and other infrastructure.

Send your message to us

Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords