Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar

Product Details of Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar:

1. Material: Alloy structural steels, carbon structure steels, alloy tool and model steels,etc.

2. Process: EAF + LF + VD + Forged + Heat Treatment (optional)

3. Delivery condition:Hot forged +Rough machined (black surface after Q/T)+ Turned (optional)

4.Technical Data: Chemical Composition, Physical Properties and Mechanical Testing.

5. Test: Ultrasonic test according to SEP 1921-84 3C/c.

Chemical Composition of Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar:

C | Si | Mn | P | S | Cr | |

45Cr | 0.42-0.49 | 0.17-0.37 | 0.6-0.9 | Max0.035 | Max0.035 | 0.3 0.4 |

S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | Max0.030 | Max0.035 | |

1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | Max0.030 | Max0.050 |

Application of Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar:

1 Can be used in many fields such as building, automobile, shipbuilding,

petrochemical, machinery, medicine, food, electric power, energy, space, building

and decoration, etc.

2 Can be made into mould template, mortise pin, column

3 This kind of steel have good mechanical property, is widely used in structural parts

4 which may support stress alternation, especially made into some connecting

rods, bolts, wheel gear...

5 This kind of steel is the most common blanks and materials of shaft part

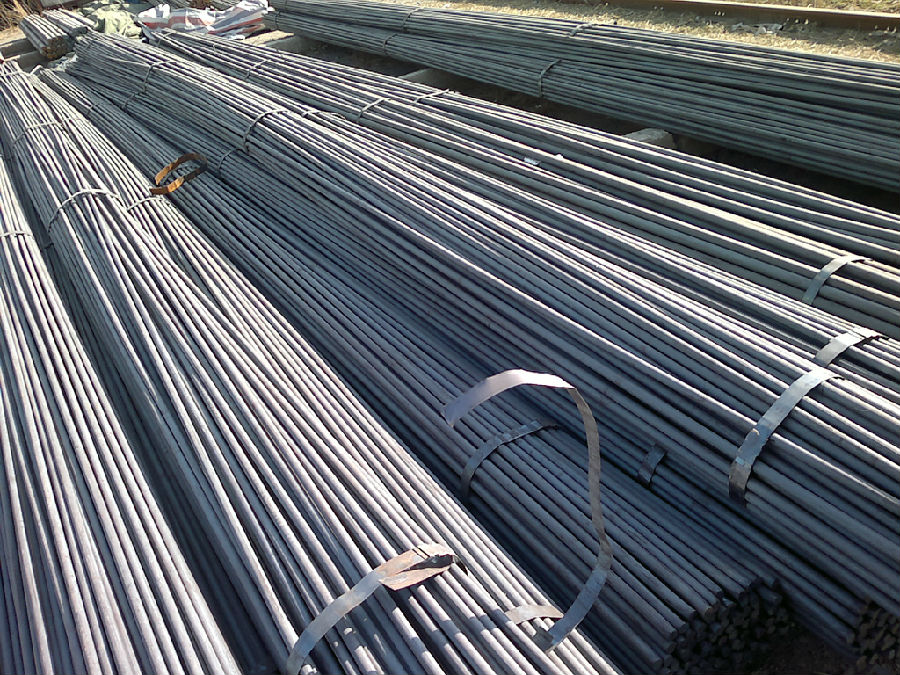

Images of Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar

- Q: Are steel round bars suitable for use in the construction industry?

- Yes, steel round bars are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support in various applications such as reinforcement in concrete, framing, and the creation of beams and columns. Additionally, steel round bars can be easily fabricated, welded, and formed into different shapes, making them a suitable choice for a wide range of construction projects.

- Q: What is the tolerance level for steel round bars?

- The tolerance level for steel round bars can vary depending on the specific industry standards and requirements, but commonly, it falls within a range of +/- a few millimeters or less.

- Q: Is there any technique for welding round steel?

- The welding position is horizontal fillet welding, to control the size of the weld pool of available elliptic transport method the molten iron is brought up, and then try to consider the position of welding welding (a little more than half of small to)

- Q: Can steel round bars be used in the fabrication of machinery?

- Yes, steel round bars can definitely be used in the fabrication of machinery. Steel round bars are commonly used in the manufacturing industry for various applications, including the fabrication of machinery and equipment. They possess several desirable properties that make them suitable for this purpose. Firstly, steel round bars offer excellent strength and durability. They are known for their high tensile strength, which means they can withstand heavy loads and resist deformation. This strength is crucial in machinery fabrication, as the components of machinery need to be able to endure the stresses and forces that they will be subjected to during operation. Additionally, steel round bars have good machinability, which means they can be easily shaped and formed into the desired components for machinery. This makes them highly versatile and allows for the creation of complex and intricate machine parts. Furthermore, steel round bars have good resistance to corrosion and wear, which is essential in machinery fabrication. Machinery often operates in harsh environments or comes into contact with various substances, such as chemicals, oils, or abrasive materials. The corrosion and wear resistance of steel round bars ensure that the fabricated machinery can withstand these conditions and maintain its performance over time. Lastly, steel round bars are readily available and cost-effective. They can be easily sourced from suppliers and manufacturers, making them a practical and economical choice for machinery fabrication. Overall, steel round bars are a popular and reliable material for the fabrication of machinery. Their strength, machinability, resistance to corrosion and wear, and availability make them an ideal choice for creating durable and high-performing machine components.

- Q: What are the advantages of using nickel-alloy steel round bars?

- There are several advantages of using nickel-alloy steel round bars. Firstly, nickel-alloy steel has excellent corrosion resistance, making it suitable for use in harsh environments or applications where the material is exposed to corrosive elements. Secondly, nickel-alloy steel possesses high temperature strength and resistance to thermal expansion, making it ideal for use in high-temperature applications such as aerospace or power generation. Additionally, nickel-alloy steel offers good mechanical properties, including high tensile strength and toughness, which make it suitable for demanding applications that require strength and durability. Overall, the use of nickel-alloy steel round bars provides a combination of corrosion resistance, high-temperature strength, and mechanical properties, making it a versatile and reliable material choice in various industries.

- Q: Do steel round bars have a maximum load capacity?

- Steel round bars do possess a maximum load capacity. The load capacity is determined by several factors, including the bar's diameter, length, type and grade of steel, and the industry standards or specific application it is used for. Testing and analysis are typically employed to determine the load capacity, taking into account factors like yield strength, ultimate tensile strength, and the bar's ability to withstand bending or deformation under load. To maintain safety and structural integrity, it is crucial to refer to engineering specifications and guidelines to prevent exceeding the maximum load capacity of a steel round bar.

- Q: What are the different types of steel round bars used in the automotive aftermarket?

- In the automotive aftermarket, there is a wide variety of steel round bars used. Some commonly seen types include: 1. Carbon Steel Round Bars: Due to its exceptional strength and durability, carbon steel is widely employed in the automotive industry. It finds its application in heavy-duty performance areas like suspension components, drive shafts, and steering linkages. 2. Alloy Steel Round Bars: Alloy steel, which is steel combined with other elements to enhance its mechanical properties, is prevalent in the automotive aftermarket. Applications requiring high strength, such as crankshafts, camshafts, and axles, commonly use alloy steel. 3. Stainless Steel Round Bars: Noted for its resistance to corrosion and attractive appearance, stainless steel is often preferred for automotive aftermarket applications in harsh environments. Exhaust systems, trim components, and decorative elements are examples that benefit from stainless steel's resistance. 4. Tool Steel Round Bars: Tool steel, a specialized high-carbon steel, is designed specifically for tooling and machining applications. In the automotive aftermarket, it is widely used for manufacturing specialized tools, dies, and molds. 5. Bearing Steel Round Bars: Bearing steel, another type of high-carbon steel, is tailored for bearing applications. In the automotive aftermarket, bearing steel is commonly utilized for manufacturing bearings and other rotating components. These examples represent just a small sample of the steel round bars found in the automotive aftermarket. The choice of steel for each specific application will depend on factors such as desired strength, durability, and resistance to corrosion.

- Q: Can steel round bars be used in the manufacturing of garden tools?

- Yes, steel round bars can be used in the manufacturing of garden tools. Steel is a durable and robust material that offers strength and resistance, making it suitable for various garden tools such as shovels, rakes, hoes, and spades. The round bars can be shaped and formed to create the desired tool design and functionality, ensuring durability and longevity in outdoor conditions.

- Q: What are the advantages of using phosphorus-alloy steel round bars?

- There are several advantages of using phosphorus-alloy steel round bars: 1. Increased strength: Phosphorus-alloy steel round bars have a higher tensile strength compared to standard steel bars. This increased strength makes them suitable for applications that require greater load-bearing capacity, such as construction and automotive industries. 2. Enhanced corrosion resistance: Phosphorus-alloy steel has a higher resistance to corrosion compared to regular steel. This makes it more durable and long-lasting, especially in environments with high moisture or exposure to chemicals. 3. Improved machinability: Phosphorus-alloy steel has excellent machinability, which means it can be easily shaped, cut, and formed into various designs or structures. This characteristic makes it a preferred choice for industries that require precise shaping, such as manufacturing and engineering. 4. Reduced brittleness: Phosphorus-alloy steel has a lower brittleness factor compared to other types of steel. This means it is less likely to break or fracture under sudden impact or stress, making it a safer option for applications where structural integrity is crucial. 5. Cost-effective: Despite its enhanced properties, phosphorus-alloy steel round bars are still cost-effective compared to other specialty alloys. This makes them a more affordable choice for industries that require high-performance materials without breaking the budget. 6. Improved weldability: Phosphorus-alloy steel round bars have excellent weldability, allowing for easy and secure welding connections. This characteristic makes them suitable for applications that require strong and reliable welded joints, such as construction or fabrication projects. In summary, phosphorus-alloy steel round bars offer increased strength, enhanced corrosion resistance, improved machinability, reduced brittleness, cost-effectiveness, and improved weldability. These advantages make them a preferred choice for various industries where high-performance materials are required.

- Q: Can steel round bars be used in the marine industry?

- Yes, steel round bars can be used in the marine industry. Steel is a preferred material in the marine industry due to its excellent strength, durability, and corrosion resistance properties. Round bars made of steel are commonly used for various applications in the marine industry, such as building ship hulls, constructing offshore structures, manufacturing marine equipment and components, and creating mooring systems. Steel round bars can withstand the harsh conditions of the marine environment, including exposure to saltwater, waves, and extreme weather conditions. Additionally, steel round bars can be easily fabricated, welded, and machined, making them a versatile choice for marine applications.

Send your message to us

Round Bar SAE 1045, AISI 1045,CK45, 1.119,S45C Hot Rolled Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 34000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords