Goodman Aluminum Coils - PVDF Coating Aluminum Coils for ACP Application with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

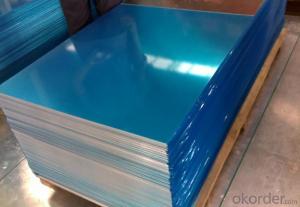

1. Structure of PVDF Coating Aluminium Coils for ACP Application with High Quality

PVDF coated aluminum coils are with excellent acid-resistance and alkali-resistance. They are green decoration materials with characters of environment protection, flame-resistance, and groovy colors. In nowadays, the color coated aluminum coil has become the popular material for top grade decoration.

Color coated aluminum coils are widely used for aluminum composite panels. We normally use alloy 3003 and temper H16.

We have different colors for aluminum composite panels. RAL numbers are no problem for us. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of PVDF Coating Aluminium Coils for ACP Application with High Quality

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

3. PVDF Coating Aluminium Coils for ACP Application with High Quality Images

4. Specification of PVDF Coating Aluminium Coils for ACP Application with High Quality

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a] AL is used to make frames because it is light, not costly and strong.

- Q: What are the acoustic properties of buildings using aluminum coils?

- The acoustic properties of buildings using aluminum coils can be influenced by various factors. Aluminum coils are commonly used in the construction industry for roofing, cladding, and insulation purposes. From an acoustic perspective, these properties can have both positive and negative impacts on the sound transmission within a building. One of the primary acoustic benefits of using aluminum coils is their ability to act as a reflective barrier for sound waves. When properly installed, aluminum coils can help prevent sound from penetrating through walls or ceilings, resulting in a reduction in external noise sources. This can be particularly beneficial in areas with high levels of noise pollution, such as urban environments or near busy roads. Additionally, aluminum coils can contribute to the overall sound insulation of a building. Due to their material properties, they can provide a certain level of soundproofing, especially when combined with other insulation materials. This can help maintain a comfortable and quiet indoor environment, allowing for improved concentration, productivity, and overall well-being of occupants. However, it is important to note that the acoustic properties of buildings using aluminum coils can also have limitations. Aluminum is a lightweight material compared to alternatives like concrete or brick, which means it may not provide as much mass to block sound transmission. Therefore, in situations where high sound insulation is required, additional measures such as double glazing, acoustic seals, or thicker wall constructions may be necessary. Furthermore, the use of aluminum coils can also affect the sound reverberation within a space. Due to their smooth and reflective surface, aluminum coils can potentially cause sound waves to bounce off, leading to increased echo and reverberation time. This can negatively impact speech intelligibility and acoustic comfort, especially in larger open-plan areas or rooms with high ceilings. Overall, while aluminum coils can offer certain acoustic advantages such as sound reflection and insulation, it is important to consider the specific requirements of each building project. Consulting with acoustic engineers or professionals can help ensure that the appropriate measures are taken to optimize the acoustic properties of buildings using aluminum coils, and to address any potential limitations.

- Q: Are there any limitations to the widths of aluminum coils?

- Yes, there are limitations to the widths of aluminum coils. The width of aluminum coils is typically determined by various factors such as the manufacturing process, equipment capabilities, and industry standards. One limitation is the maximum width that the manufacturing equipment can handle. Coil processing machines have specific width capacities, which generally range from a few inches to several feet. If an aluminum coil exceeds the maximum width that the machine can accommodate, it may not be possible to process it. Another limitation is related to transportation and handling. Aluminum coils that are too wide may not fit within standard shipping containers or may be difficult to maneuver during transportation. Additionally, wide coils may require specialized handling equipment or additional support, which can increase costs and logistical challenges. Industry standards and application requirements also play a role in determining the limitations of aluminum coil widths. Different industries and applications have specific width requirements for their products. For example, the construction industry may have specific width specifications for roofing or cladding materials, while the automotive industry may have different requirements for body panels. Manufacturers need to consider these standards and customer needs when determining the maximum and minimum widths of aluminum coils. In summary, while aluminum coils can be produced in various widths, there are limitations due to manufacturing equipment capabilities, transportation constraints, and industry standards. These limitations must be considered to ensure the efficient production, handling, and utilization of aluminum coils in different applications.

- Q: This question asks about the environmental impact of aluminum coils, including potential effects on the ecosystem and human health.

- <p>Aluminum coils, when produced and used responsibly, have minimal environmental impact. However, improper disposal or manufacturing can lead to pollution. Aluminum production requires significant energy, contributing to greenhouse gas emissions. During manufacturing, if not managed properly, can release harmful substances into the air and water. Yet, aluminum is highly recyclable, reducing its environmental footprint over time. When disposed of improperly, aluminum can contribute to litter and leach harmful substances into the soil and water, affecting wildlife and potentially human health. Responsible recycling and manufacturing practices are crucial to mitigate these effects.</p>

- Q: Can aluminum coils be insulated?

- Indeed, insulation can be applied to aluminum coils. It is a widespread practice to enhance energy efficiency and avoid heat loss or gain. Usually, the insulation material envelops the aluminum coil, creating a safeguarding coating that minimizes thermal transfer. This insulation method contributes to preserving the desired temperature within the coil and averting detrimental condensation. Moreover, insulation additionally enhances the overall functionality and durability of the aluminum coil system.

- Q: should i have a paper between aluminum siding and the wood

- Aluminum siding can be vented with round pop-in perforated vent plugs, these are very easy to install. I would really like to know how do you know there is condensation behind your siding?

- Q: Is it possible to use aluminum coil as a material for crafting jewelry?

- <p>Yes, you can use aluminum coil to make jewelry. Aluminum is lightweight, affordable, and easy to work with, making it a popular choice for crafting. It's also hypoallergenic, which is a plus for those with metal sensitivities. However, it's softer than metals like sterling silver or gold, so it may require more care to prevent denting or bending. Aluminum can be shaped, cut, and polished to create various jewelry designs, but it may not hold up as well over time or under heavy use compared to harder metals.</p>

- Q: A bit of a question for the 1911 experts roaming around here. Per-say someone, who knew their way around a 1911 built one on an aluminum frame. To top it all off, if the finished gun were to be chambered in .38 super... how long would this combination last? I've heard horror stories about aluminum frames, and then I've heard some wonderful things... this question was to see if anyone had ever thought about/done this sort of thing before. Something tells me that Aluminum + .38 super wouldn't last too long... Most informative answer gets the ten point prize as usual.

- I have two concerns about using an aluminum frame for that caliber. First, and like everyone else who answered, I don't think it will stand up to the .38 Super +P for very long (and I wouldn't want to be around when it fails). Second, the reason I believe the frame will not last nearly as long as a steel or stainless (my personal suggestion) frame is that the grooves the slide fits and rides in will wear and enlarge MUCH faster than a steel or stainless frame will. This will, in my opinion, also quickly have an adverse affect on accuracy. Aluminum has it's place, but I don't think it's anywhere near this kind of firearm. On a side note, one of the other people who answered said that the aluminum will offer some corrosion resistance. This may generally be true, but salt water (like sweat) attacks aluminum significantly faster than it does steel, and stainless steel is almost non-reactive to it. If he wants a lighter gun for carry, Try an XD45. If I remember right they are rated for .45 +P, but call Springfield Armory to make sure. With the polymer frame they are much lighter than a 1911, and I have been very satisfied with the accuracy and the reliability of mine. Personally, I don't think the weight savings of the alloy frame is worth the extra care to keep from sweating on it or the much shorter lifespan the gun will likely have. If he isn't planning on carrying it, what is the point of lightening the gun? He'll feel a lot more recoil, especially if he does shoot the +P ammo.

- Q: Can aluminum coils be used for magnetic purposes?

- No, aluminum coils cannot be used for magnetic purposes. Aluminum is a non-magnetic material, meaning it does not have any magnetic properties. In order to use coils for magnetic purposes, materials with magnetic properties such as iron or steel are commonly used. These materials can generate and conduct magnetic fields, whereas aluminum cannot.

- Q: i dont want aluminum cookware, but how about a stainless steel set with an aluminum core. Is this the same as aluminum pots and pans? Thanks.

- The aluminum is encased in the stainless steel, usually as a thick disk in the bottom. It is an excellent conductor of heat and holds the heat well once it gets hot. All you see is the stainless, none of the aluminum because it's between two layers of stainless in the bottom of the pots. You are right, you don't want food cooked in straight aluminum, some metal taste can transfer to certain foods. That won't happen with stainless.

Send your message to us

Goodman Aluminum Coils - PVDF Coating Aluminum Coils for ACP Application with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords