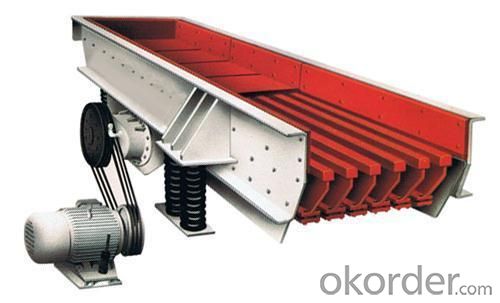

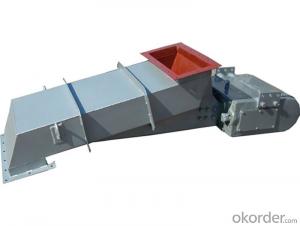

Grizzly Vibrating Feeder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Grizzly vibrating feeder:

pe | Outline size | Feeding size(mm) | Capacity | Vibration frequency | Double amplitude | Electric motor Power | |

Width(mm) | Length(mm) | ||||||

(t/h) | (time/min) | (mm) | (kw) | ||||

GZT1020 | 1000 | 2000 | 700 | 120 | 835 | 7~9 | 7.5 |

GZT0735 | 750 | 3500 | 500 | 105 | 835 | 7~9 | 7.5 |

GZT0740 | 750 | 4000 | 500 | 105 | 835 | 7~9 | 7.5 |

GZT0930 | 900 | 3000 | 600 | 120 | 835 | 7~9 | 7.5 |

GZT0940 | 900 | 4000 | 600 | 130 | 835 | 7~9 | 11 |

GZT0945 | 900 | 4500 | 600 | 135 | 835 | 7~9 | 15 |

GZT0950 | 900 | 5000 | 600 | 140 | 835 | 7~9 | 15 |

GZT1140 | 1100 | 4000 | 750 | 180 | 835 | 7~9 | 18.5 |

GZT1145 | 1100 | 4500 | 750 | 200 | 835 | 7~9 | 18.5 |

GZT1150 | 1100 | 5000 | 750 | 220 | 835 | 7~9 | 22 |

GZT1250 | 1200 | 5000 | 850 | 330 | 835 | 7~9 | 30 |

GZT1560 | 1500 | 6000 | 1200 | 700 | 835 | 7~9 | 30 |

Usage of Grizzly vibrating feeder:

Our feeder series have two types :vibrating feeder and liear feeder .Vibrating feeder series have two engines.Users can adjust vibrating frequency of feeder freely so as to completely control feeding speed of stone material and ensure smooth operation of production line. Linear feeder has feature of stable vibration,reliable operation and long service life ,can feed crushing machine continously and has primary sieving on materials.It is widely used in crushing and screening plants of mining ,construction materials ,silicate and chemical industry.

Feature of GZD / ZSW Vibrating Feeder

1. It can divide into two types: vibrating feeder and linear feeder.

-- Vibrating feeder series has two vibrating motors, so our customers can freely adjust the feeder vibrating frequency so as to completely control feeding speed of stone material;

--Linear feeder has features of stable vibration, reliable operation and long service life.

2. It can realize the continuously and uniformly feeding for the crushing machines, as well as can finish the coarse sieving on material.

Picture of Grizzly vibrating feeder:

- Q: What's the application of ore shaker?

- [ore vibrating screen] advantages1, large processing capacity, high screening efficiency.2 、 the vibrator is lubricated by bearings, thin oil lubrication, and external block eccentric structure. The utility model has the advantages of large exciting force, small bearing load, low temperature, small noise, etc.. (bearing temperature rise less than 35 degrees).3, the vibrator whole assembly and disassembly, maintenance and replacement is convenient, greatly shorten the overhaul cycle. (it only takes 1~2 hours to replace the vibrator).4 、 the side plate of the screen machine adopts cold cold welding, no welding, high strength and long service life. The connection between the beam and the side plate is made of anti twist shear and high strength bolt. It is easy to replace without welding or cross beam.

- Q: How to choose vibrating motor of perlite linear sieve?

- The vibration motor is provided with a set of adjustable eccentric blocks at both ends of the rotor shaft, and the exciting force is generated by the centrifugal force generated by the high-speed rotation of the shaft and the eccentric block. Vibration motor vibration frequency range is large, only the excitation power and power match properly, can reduce the mechanical noise. Vibration motors are classified according to the starting and operating modes, and classification according to the speed of operation, and so on. There are six kinds of vibration motors.

- Q: What are the advantages of ultrasonic vibrating screen?

- 1. ultrasonic vibration sieve technology for different materials, such as particle size, density and particle shape, screening, research and development and production;2., it has solved the sieving problems of strong adsorption, easy to hold together, strong stickiness, high static electricity, high density, superfine powder and other characteristics;

- Q: Why is the bearing of the vibrating screen overheated?

- By choosing the proper grease, the grease is also lubricated, and the high frequency instantaneous impact stress is alleviated, and the temperature of the bearing is lowered.Use the right bearings. Because the bearings need to withstand the high frequency vibration load of the vibrating screen, and the load has been changing. If the special bearing of the vibrator is not selected, the radial clearance of the bearing will be too small.Regular inspection of the sealing of the bearings, to prevent the outside of slime, water, etc., into the bearing's interior. Regular cleaning of bearings, regular replacement of lubricating oil and seals.

- Q: What are the technical requirements of the vibration screen installation?

- The horizontal levelness of the vibrating screen is 1mm/m.

- Q: What are the differences between MB and Ma bearings for vibration screens?

- Hello, according to your description:Bearing MA room, the outer ring to guide the rolling mode, the specific design of the above bearing roller and inner ring is a gap.MB is the inner circle guide rolling mode, the specific design is roller close to the inner ring, guided by the inner ring.Handmade, thank you for your adoption, and what questions, please continue to ask!

- Q: How many levels should the vibrating motor of the vibrating screen be equipped with?

- 2 1.1KW, YZS15-6 vibration motors, class 6.If the number of layers is larger, use 1.5KW, YZS20-6.

- Q: Who can introduce the common frame of the vibrating screen?

- Net type composite grid structure is a network among the vibrating screen equipment the most simple, the most common and the most widely used and most of the net is not easy. The grid is divided into double net type, mesh on coarse mesh in the stack, can support the fine mesh, prevent material screening process due to gravity fine play the pocket affect the screening efficiency caused by.

- Q: Why should shale shaker be used for vibrating screen?

- Long service life: the unique production process of polyurethane screen mesh makes the material and screen mesh have only a little friction, and the impact force is greatly reduced.

- Q: What are the precautions in the installation of vibrating screens?

- Common trouble shooting of equipment:1) seals are damaged faster:Observe whether the beam ring is locked - fasten the tie ring boltThere are traces of movement - securing the beam ring boltsMaterial temperature: replace seals, material for high temperature sealing.2) the screen is easy to damage:The screen does not tighten - replace the adjusting screenUneven material - change the blanking method or install the distributorInstant more material - change the blanking way or install cloth distributorForeign material in the material - pay attention to the control of the process

Send your message to us

Grizzly Vibrating Feeder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords