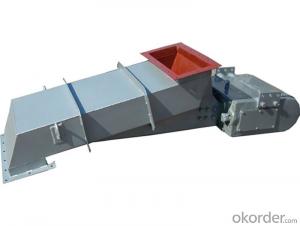

Motor vibrating feeder for crushing production line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Motor vibrating feeder for crushing production line

Product overview of Motor vibrating feeder for crushing production line:

Motor vibrating feeder for crushing production line in the production process, The massive, granular materials from the storage silos in uniform, regular and continuous charging and feeding device. In the gravel production line, can continuous and uniform feeding for crushing machinery. Also could give the roughly sieve for materials.

Application of Motor vibrating feeder for crushing production line:

Widely used in metallurgy, coal, mineral processing, building materials, chemical industry, abrasive and other industries of crushing, screening combined equipment.

Advantages of Motor vibrating feeder for crushing production line:

1.The structure is simple, light weight, low noise, reliable work, high capacity, easy installation and maintenance.

2.Start quickly, stable, stable parking.

3.The material groove wear smaller.

4.Can be instantaneous change and open and close the material flow, so the feed volume has a higher accuracy.

Technical parameter table of Motor vibrating feeder for crushing production line:

Model | Groove size width × length × height(mm) | Productivity(t/h) | Maximum feed size(mm) | Double amplitude (mm) | Vibrator model | Rated current (A) | Power (kw) | Total Weight (kg) |

GZG403 | 400×1000×200 | 30 | 60 | 4 | ZG405 | 2×0.73 | 2×0.25 | 163 |

GZG503 | 500×1000×200 | 60 | 60 | ZG405 | 2×0.73 | 2×0.25 | 202 | |

GZG703 | 700×1000×250 | 120 | 80 | ZG415 | 2×1.95 | 2×0.75 | 414 | |

GZG903 | 900×1500×250 | 170 | 80 | ZG415 | 2×1.95 | 2×0.75 | 605 | |

GZG1003 | 1000×1750×315 | 250 | 100 | ZG420 | 2×2.71 | 2×1.1 | 813 | |

GZG1253 | 1250×2000×315 | 320 | 100 | ZG432 | 2×3.51 | 2×1.5 | 1072 | |

GZG705 | 700×1000×250 | 120 | 80 | 6 | ZG612 | 2×1.66 | 2×0.75 | 307 |

GZG905 | 900×1500×250 | 160 | 80 | ZG612 | 2×1.66 | 2×0.75 | 577 | |

GZG1005 | 1000×1750×315 | 220 | 100 | ZG618 | 2×2.97 | 2×1.1 | 817 | |

GZG1255 | 1250×2000×315 | 270 | 100 | ZG625 | 2×3.84 | 2×1.5 | 1077 |

- Q: The opening process of press filter from feeding to discharging is described briefly

- Open the central blowback return valve, send compressed air, and clean the inlet channel. The time is set according to the experience and the setting time.

- Q: What's the simplest ore radio to do?

- 2AP9 diode is a 600 ohm above the earplug foil 65 cm long 2 cm wide kraft paper a 70 cm long 3 cm wide and 3 meters to a copper wire wrapped in kraft paper in electric wire and copper wire tin foil wrapped in kraft paper outside the 3 meter long wire peeling exposed around 1 meters above the other foil one end is connected with the grounding wire and radio headset diode parallel diode cathode copper wire electrode tap water pipe is connected with a tap water pipe line lamp is very simple and don't pay attention to the leakage

- Q: Which God knows, hammer crusher, according to the material into which there are several categories?

- Axial feed from the main shaft into the crushing chamber, suitable for crushing grain, but after feeding the entrance to install slices, but also crushing grass, stems and so on.

- Q: How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size and production capacity of crushing equipment, whether it is what it needs

Send your message to us

Motor vibrating feeder for crushing production line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches