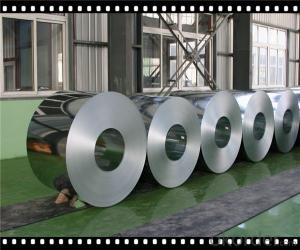

good quality prepainted steel coil for construction of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,DIN,GB,JIS | Grade: | cold rolled,first grade | Thickness: | 0.14-3.0,0.14mm-1.6mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | cnbm | Model Number: | prepainted steel coil |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Width: | 600-1500,600-1250mm | Length: | coil | color: | According to Ral color card or sample |

| other: | emboss, wood gain, film cover | coil ID: | 508mm, 610mm | zinc caoted: | 60g-275g |

| painted thickness: | 8-75um | Layers of the coating: | 2/2, 2/1, 1/1 | Product Name: | prepainted steel coil |

Packaging & Delivery

| Packaging Detail: | prepainted steel coil export packing |

| Delivery Detail: | 20 days after prepayment |

Specifications

prepainted steel coil

prepainted galvanized steek thickness 0.14mm-1.6mm, width 600mm-1500

prepainted steel coil

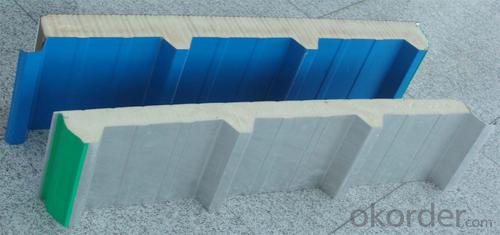

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets. The structure of prepainted steel includes finished coating, primer coating, chemical conversion coating metallic coating and cold-rolled steel. The prepainted steel sheets are mainly provided for various commercial purposes covering architectural construction, electrical household appliances, transportation, etc.

Type of coating structure

2/1: Coat the top surface of the steel sheet twice, coat the lower surface once, and bake the sheet twice.

2/2: Coat the top/lower surface twice and bake twice.

Pre painted Hot dip galvanized steel coil thickness 0.14mm-1.6mm, width 600mm-1500 color coated steel Coil

Specifications:

Base Metal | Hot dipped galvanized steel | DX51D+Z | Normal use |

DX52D+Z | For drawing | ||

DX53D+Z | For deep drawing | ||

S280GD+Z | Structure | ||

S350GD+Z | Structure | ||

S550GD+Z | For high-strength structure | ||

Hot dipped galvalume steel | DX51D+AZ | Normal use | |

DX52D+AZ | For drawing | ||

DX53D+AZ | For deep drawing | ||

S280GD+AZ | Structure | ||

S350GD+AZ | Structure | ||

S550GD+AZ | For high-strength structure | ||

Thickness | 0.14mm-1.6mm | ||

Width | 600mm-1500mm | ||

Coil ID | 508mm, 610mm | ||

Layers of the coating | 2/2(2 layers of top coating/2 layers of bottom coating); 2/1(2 layers of the top coating, 1 layer of bottom coating); 1/1(single layer of top coating/ single layer) | ||

Color | According to customers’ request | ||

Coated | ZN60-ZN275 or AZ60-AZ180 | ||

Paint | PE, HDP, SMP, HPC, PVDM | ||

Thickness of the coating | 25um-75um | ||

Surface | Film coverd | ||

grade | CGCC | Normal use |

CGCD 1 | For drawing | |

CGCD 2 | For deep drawing | |

CGC 440 | Structure | |

CGC 490 | Structure | |

CGC 570 | For high-strength structure | |

Thickness | 0.14mm-1.6mm | |

Width | 600mm-1500mm | |

Coil ID | 508mm, 610mm | |

Layers of the coating | 2/2(2 layers of top coating/2 layers of bottom coating); 2/1(2 layers of the top coating, 1 layer of bottom coating); 1/1(single layer of top coating/ single layer) | |

Color | According to customers’ request | |

Paint | PE, HDP, SMP, HPC, PVDM | |

Thickness of the coating | 25um-75um | |

Surface | Film coverd | |

Applications:

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

other | writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment |

- Q: What are some of the greatest steel guitar songs in the history of country music. Western swing applies also.

- the answer would could be chum Emmons..he's performed with a number of the excellent artists in Nastyville!!! he's the guy who made all those Ray fee songs so bone chilling.

- Q: How are steel coils inspected for dimensional accuracy after processing?

- Steel coils are inspected for dimensional accuracy after processing using various methods such as measuring tape, calipers, laser scanners, or automated vision systems. These tools allow for precise measurements of the coil's width, thickness, and length, ensuring that it meets the required specifications.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- In that video, he is using a steel-string acoustic guitar. However, when choosing between a nylon string guitar and a steel string guitar, you must consider a few things. Steel-string guitars are more painful in the beginning for the fretting hand, but that means you'll have more strength in your fingers faster. Nylon-string guitars are easier on the fingers and sound much smoother and calmer than steel-string guitars. Also, nylon-string guitars have a wider neck and that neck meets the body at the twelfth fret, while most steel-string guitars have a thinner neck that meets the body at the fourteenth fret. Have fun with your first guitar! :)

- Q: How are steel coils inspected for quality control?

- Steel coils are inspected for quality control through various methods. These methods include visual inspections, dimensional measurements, and non-destructive testing techniques such as ultrasonic testing or magnetic particle inspection. Additionally, the coils are checked for surface defects, such as scratches or corrosion, and are also examined for proper labeling and packaging to ensure they meet the required quality standards.

- Q: Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- I have never heard of stainless steel paint, but I know that stainless steel is hard to clean and maintain

- Q: How do steel coils compare to other materials like aluminum or copper?

- When comparing steel coils to other materials like aluminum or copper, it is evident that they possess both advantages and disadvantages. One primary advantage of steel coils lies in their remarkable strength and durability. Steel is renowned for its high tensile strength, enabling it to withstand heavy loads and high stress without any deformation. As a result, steel coils are highly suitable for various applications that demand robust and resilient materials, including construction, automotive manufacturing, and transportation industries. In contrast, aluminum and copper are generally softer and less strong than steel, rendering them less appropriate for heavy-duty tasks. Another advantage of steel coils is their cost-effectiveness. In comparison to aluminum or copper, steel is a relatively inexpensive material, making it a more accessible option for large-scale projects or mass production. Furthermore, steel is highly recyclable, contributing to its cost-effectiveness and sustainability. Nonetheless, steel coils do have some disadvantages when compared to aluminum or copper. One notable drawback is their weight. Steel is significantly denser than aluminum or copper, resulting in heavier steel coils that can be more challenging to handle and transport. This disadvantage can prove to be critical in industries where weight plays a vital role, such as aerospace or electrical applications. Additionally, steel coils are susceptible to corrosion, which is another disadvantage. While aluminum and copper possess natural corrosion resistance, steel is prone to rust and oxidation. Consequently, steel coils require proper protection and coating to prevent corrosion, which adds to the overall cost and maintenance requirements. In conclusion, steel coils offer exceptional strength, durability, and cost-effectiveness when compared to aluminum or copper. However, they are generally heavier and more prone to corrosion. Ultimately, the selection between steel, aluminum, or copper will depend on the specific application, budget, and project requirements.

- Q: I don't know it is low alloy steel or high allow steel or medium carbon steel

- Yes,30CrNiMo8 is a high grade alloy steel. *These steels generally contain higher carbon concentration (0.25%). As they are hardenable their mechanical properties can be tailored to specific needs by suitable adjustment of the annealing temperature. Finished products can be hardened to have a high surface hardness in combination with a tough and ductile core. The mechanical properties increase with increasing carbon concentration. Cr and Ni add additional improvements in properties. The Mn grades are a little cheaper. V and Mo add improved temperature resistance. The grades Cxx are developed for less stringent quality requirements but are cheaper.

- Q: Cast steel welding

- Normal okorder /.. Mild steel and cast steel produces a very long stream of brilliant sparks, with some forking. CI produces much shorter, dull reddish sparks and the volume of sparks is much less. many highly branched or intermittent sparks will be seen.

- Q: How are steel coils used in the manufacturing of roofing materials?

- Steel coils are used in the manufacturing of roofing materials by being processed and shaped into various forms such as sheets, shingles, or panels. These coils are typically coated with protective layers to enhance durability and resistance to corrosion. The coils are then cut, formed, and assembled to create the final roofing product, ensuring strength, reliability, and longevity for the roofs.

- Q: Can steel coils be coated with chemical-resistant materials?

- Yes, steel coils can be coated with chemical-resistant materials. These coatings provide a protective barrier against chemical corrosion and can help extend the lifespan of the steel coils in environments where they may be exposed to corrosive chemicals or substances.

Send your message to us

good quality prepainted steel coil for construction of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords