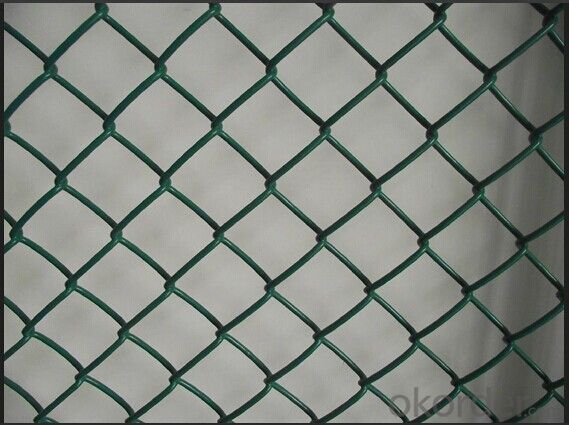

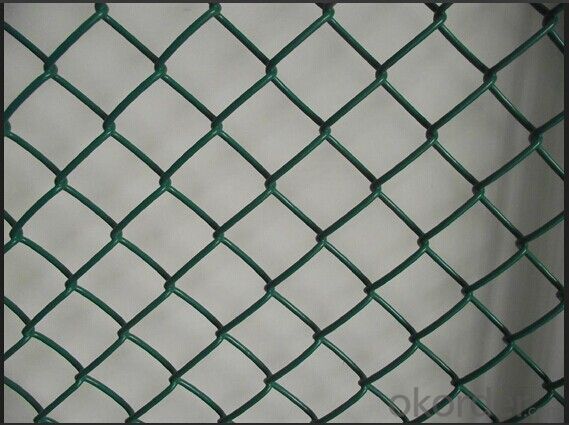

Good Quality Gabion wire mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

wire mesh

1. CE, ISO9001:2008

2. High Quality Low Price

3.Galvanized wire, PVC coated

4.Delivery: 10 days

Woven wire mesh

Stainless Steel Wire Mesh:

We produce stainless steel wire mesh from first class stainless steel wire material in SUS/AISI 201 202 302 304 310 310S 316 316L 321 430 etc.

Stainless steel wire mesh with its excellent resistance against acid, alkali, heat and corrosion, find extensively uses in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

Stainless steel wire mesh | ||||||

mesh/inch | wire diameter mm | aperture mm |

| mesh/inch | wire diameter mm | aperture mm |

2mesh | 1.80 | 10.90 | 60mesh | 0.15 | 0.273 | |

3mesh | 1.60 | 6.866 | 70mesh | 0.14 | 0.223 | |

4mesh | 1.20 | 5.15 | 80mesh | 0.12 | 0.198 | |

5mesh | 0.91 | 4.17 | 90mesh | 0.11 | 0.172 | |

6mesh | 0.80 | 3.433 | 100mesh | 0.10 | 0.154 | |

8mesh | 0.60 | 2.575 | 120mesh | 0.08 | 0.132 | |

10mesh | 0.55 | 1.990 | 140mesh | 0.07 | 0.111 | |

12mesh | 0.50 | 1.616 | 150mesh | 0.065 | 0.104 | |

14mesh | 0.45 | 1.362 | 160mesh | 0.065 | 0.094 | |

16mesh | 0.40 | 1.188 | 180mesh | 0.053 | 0.088 | |

18mesh | 0.35 | 1.060 | 200mesh | 0.053 | 0.074 | |

20mesh | 0.30 | 0.970 | 250mesh | 0.04 | 0.061 | |

26mesh | 0.28 | 0.696 | 300mesh | 0.035 | 0.049 | |

30mesh | 0.25 | 0.596 | 325mesh | 0.03 | 0.048 | |

40mesh | 0.21 | 0.425 | 350mesh | 0.03 | 0.042 | |

50mesh | 0.19 | 0.318 | 400mesh | 0.025 | 0.0385 | |

Width of Stainless Steel Wire Mesh: 0.6m-1.5m | ||||||

Welded Wire Mesh

Reinforcing Mesh Panel Description:

1. Reinforcing Mesh Panel also named Welded Steel Bar panel or Heavy welded wire mesh panel.

2. Wire diameter of Weded Steel Bar Panel: 5mm -16mm

3. The opening of Welded Steel Bar Panel: 75mm-300mm

4. Reinforcing Mesh Panel length: 1m - 12m

5. Reinforcing Mesh Panel width: 100cm-240cm

6. Reinforcing Mesh Panel, Wire profile: Smooth profile, or ribbed profiile.

7. Reinforcing Mesh Panel, type of material: Q235

8. Reinforcing Mesh Panel Standard size: 2.4m x 6m

9. Australian Standard: SL72,SL82.

- Q: Can aluminum foil facing be used to create a thicker pizza crust compared to standard crusts?

- <p>Yes, you can use aluminum foil facing to make a thicker pizza crust. The foil provides a solid surface to prevent the dough from spreading too thin. To achieve a thicker crust, roll out your dough to your desired thickness and place it on the foil. Make sure the edges are thicker than the center for a traditional pizza crust look. Pre-bake the crust if necessary to set its shape before adding toppings.</p>

- Q: The user is asking if they can repurpose their old aluminum foil facing to create a new pot holder or tea cozy.

- <p>Yes, you can repurpose your old aluminum foil facing to make a new pot holder or tea cozy. Aluminum foil is a good insulator and can be easily cut and shaped to fit your needs. Simply cut the foil to the desired size, fold or wrap it around the pot or tea cozy, and secure it with a rubber band or string. For a more decorative touch, you can cover the foil with fabric or use colorful foil. Always ensure that the aluminum foil does not come into direct contact with the heat source to avoid any potential fire hazards.</p>

- Q: Is inhaling aluminum oxide particles from aluminum foil dangerous to health?

- <p>Breathing in aluminum oxide particles is generally not harmful in small amounts, as the human body can handle trace amounts of aluminum. However, prolonged exposure to high concentrations of aluminum oxide dust can cause respiratory issues and may have potential health risks. It is always advisable to handle aluminum foil and other materials that could generate dust in a well-ventilated area to minimize the risk of inhalation.</p>

- Q: Can aluminum foil be utilized as a facing material for cooking in a microwave oven?

- <p>Aluminum foil facing should not be used for microwave cooking. Microwaves can cause the foil to heat up and potentially create sparks or even start a fire. It can also reflect microwaves, damaging the microwave's interior and potentially the oven itself. Always use microwave-safe materials, such as glass or microwave-safe plastic containers, for cooking in a microwave.</p>

- Q: This question asks about potential health or safety risks associated with the use of non-stick coatings on food covers or containers.

- <p>Non-stick coatings on food covers or containers are generally safe when used as directed. However, there are some concerns. High heat can cause these coatings to release potentially harmful fumes or chemicals, such as perfluorooctanoic acid (PFOA), which has been linked to health issues. It's important to avoid overheating non-stick items and to not use them in the oven or broiler. Always follow the manufacturer's guidelines for safe use and cleaning. If the coating is scratched or peeling, it's best to replace the item to prevent ingestion of the coating particles.</p>

- Q: The user is asking if it's possible to use aluminum foil with a reflective side to create a container for holding a salad.

- <p>Yes, you can use aluminum foil facing to make a salad bowl. Simply take a large piece of aluminum foil, preferably the shiny side facing out, and shape it into a bowl by folding the edges up and around. Ensure the foil is large enough to hold the salad and has no sharp edges. This makeshift bowl is great for picnics or outdoor events, but remember it's not meant for long-term storage or cooking purposes.</p>

- Q: What are the various materials used as facings for aluminum foil, and how do they differ from one another?

- <p>Aluminum foil facing materials are used in construction and insulation to provide a barrier against air and moisture. The different types include: 1) Kraft paper facing, which is a strong, absorbent paper used for general purposes; 2) Glassine facing, a thin, glossy paper with good water resistance; 3) PE-coated facing, where a layer of polyethylene is applied for enhanced water resistance; 4) Aluminum foil facing, which is a thin layer of aluminum for superior barrier properties; 5) Silicone-treated glass fabric, offering high-temperature resistance and used in high-performance applications. Each type has unique properties affecting their use in various applications.</p>

- Q: What are the potential health risks associated with the use of aluminum foil facing?

- <p>There are no significant health risks associated with the use of aluminum foil facing in everyday cooking and food storage. While aluminum is a common element and can be found naturally in many foods and water sources, the amount that might leach from foil into food is minimal and not considered harmful. However, it's always best to avoid wrapping acidic or highly salty foods in aluminum foil, as this might increase the potential for aluminum to leach into the food. For most people, the small amounts of aluminum that could come into contact with food from foil are not a health concern.</p>

- Q: Explain the distinctions among various types of aluminum foil facing materials.

- <p>Aluminum foil facing can be categorized into several types based on their composition and application. Type 1 is plain aluminum foil, commonly used for food packaging and general wrapping. Type 2 is aluminum foil laminated with plastic, which offers better barrier properties and is used in flexible packaging. Type 3 is aluminum foil laminated with Kraft paper, providing a sturdier material for packaging and insulation. Type 4 is aluminum foil laminated with polyethylene, which is waterproof and used for construction and insulation. Each type has unique properties, such as barrier resistance, strength, and heat resistance, making them suitable for different applications.</p>

- Q: Describe the most effective method for cleaning aluminum foil facing surfaces after they have been used.

- <p>The best way to clean aluminum foil facing after use is to gently wipe it with a soft, damp cloth to remove any residue or food particles. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. If there is stubborn residue, a mild dish soap can be used with warm water. After cleaning, dry the surface thoroughly to prevent water spots and potential damage. Regular cleaning helps maintain the appearance and functionality of the aluminum foil facing.</p>

Send your message to us

Good Quality Gabion wire mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords