Glass Wool Refractory Material Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

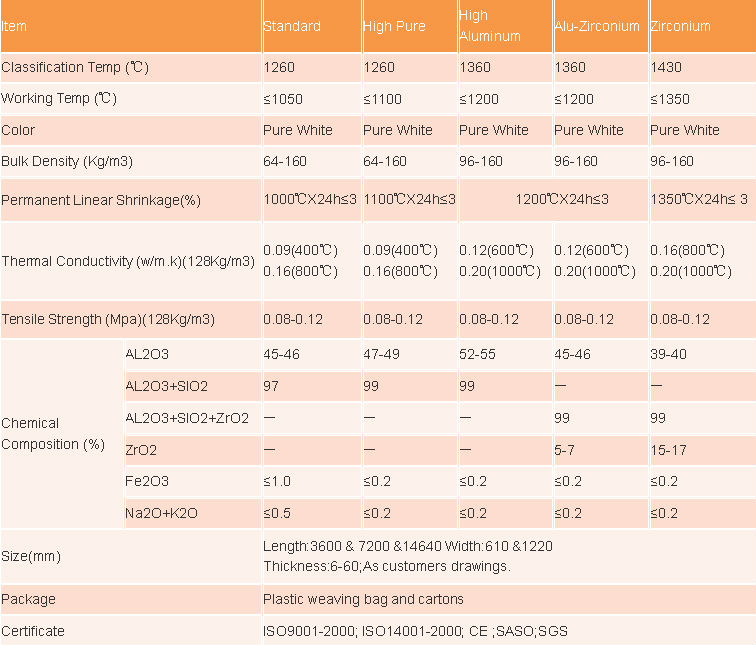

Technical Data of Ceramic Fiber Blanket

Remarks: The data above is for reference. The Max. temperature depends on the using conditions.

Product Description:

CeramicLooseFiberis made by the melted raw materials at high temperature through resistance furnace, before being blown or spun into fiber. As a neutral and acidic material, except reaction with the strong acid-alkali,refractoryceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity. Ceramic fiber is of smaller density, more than 75% lighter than insulation brick lining or 90% -95% lighter than lightweight castable lining, with thermal conductivity co-efficient to be 1/8 of the lightweight clay brick or 1/10 of lightweight heat-resistant lining (castable), and heat capacity to be 1/10 of both lightweight insulation lining and lightweight castable lining, thus to greatly lower energy loss and deliver significant energy-saving regenerative effects. Meanwhile, the ceramic fiber features a simple construction with no need of baking oven, shortened construction cycle and easy installation.

Low heat capacity and low thermal conductivity;

Excellent chemical stability;

Excellent thermal stability, resistance to pulverization at high temperature;

With no binders or corrosive substances;

Excellent sound absorption

Typical Application:

Raw material for fiber blanket, board products;

Raw material for fiber textile products;

Fillings for wall lining gap in high temperature furnace, heating device;

Raw material wet processed products;

Fiber spraying;

Castables;

Raw material for coatings;

Insulation fillings for corner and complex space.

- Q: What's the difference between the rock wool and glass wool?

- Rock wool takes natural basalt as the main raw material, after high temperature melting, artificial inorganic fibers are made by high speed centrifugal equipment, at the same time, add special binder and dustproof oil, then through heat curing, made into a variety of specifications rock wool insulation products with different requirements. Rock wool products are widely used for construction, petroleum, electric power, metallurgy, textile, national defense, transportation and other industries, is the ideal material for thermal insulation and sound insulation of pipeline storage tank, boiler, flue, heat exchangers, fan, transport and other industrial equipment. Rock wool board can resist high temperature of 650 degrees. Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance. the internal side of centrifugal glass wool exists crisscross fibers and many tiny air voids, is typical porous sound-absorbing material, has good sound absorption characteristics. Glass wool can resist high temperature of 450 degrees.

- Q: What is semi-rigid glass wool board

- Glass wool is a glass wool felt made by melting the glass after being melted by adding a binder, and the diameter of the glass wool fiber depends on the centrifugal extrusion technique

- Q: Does rock wool board refer to the glass wool ?

- The difference between rock wool and glass wool 1. same raw material, 2, same products performance, the unit weight of glass wool is lower than rock wool, less slag ball, low heat conductivity coefficient, good fiber tenacity, and the using temperature of rock wool is about 600 degrees centigrades, glass wool is about 260 degrees centigrades, 3, products application: glass wool is used for the thermal insulation parts below 200 degrees centigrades,such as construction or low temperature pipe thermal insulation, rock wool is used in thermal insulation parts under 450 degrees centigrades, such as high temperature heat pipe or electric power equipment thermal insulation.

- Q: What is the heat conductivity coefficient of glass wool ?

- Glass wool is a kind of spongiform fibre with silicate mineral which can form glass as main material and certain clinker as auxiliary material through fusion, fiber forming and a certain amount of organic binder. It belongs to inorganic glass fiber. Glass wool thermal conductivity is generally less than 0.1W / mK. If the test temperature is not high (150 ℃ or less), you can use transient plane source method. If the material itself is flocculence, you can measure without processing sample.

- Q: Can mineral wool, rock wool and glass wool thermal insulation be applied to inverted roofs?

- And wall insulation material can be applied to all kinds of roofing. Glass curtain wall Steel structures are basically solid material hanging while facade walls need adhesive and fixation and other processes.

- Q: how to choose external wall insulation materials for glass wool?

- Extrusion plate: Better physical property, small heat-transfer coefficient, low cost, suitable for buildings that requires not much exterior decoration; phenolic foam board: it can reach A level fireproof, low heat transfer coefficient, high cost. it becomes powders after hand pinching. It has poor adhesion; modified polyurethane board: It can reach A level fireproofing, low heat transfer coefficient, high cost. It can be used with various decorative materials.

- Q: How to install sound insulation glass wool boards on the wall?

- First set up the keel into the shape of a lattice, and put the glass wool board into the lattice and install the gypsum board.

- Q: Does the glass wool can be the grapes thermal insulation in winter?

- this can be the experience talk after using it. 3, or capable of burning: the glass wool you chose is A-grade material, or the A grade insulation material have this kind of glass wool as you said. 2, seedling growth conditions, thermal insulation is whether hot or cold insulation. this non-combustible material has national standard, if you want to use for external walls, you also observed carefully, but the performance of rock wool thermal insulation is poor, and there is a kind of basalt rock wool, it also have the fire side, that is non-flammable, of course, it at least 5 cm or more. Of course, you have to roast on the fire, this is pretty troubling: I suggest that if there winter is quite cold, the designing institute will issue relevant documents to work out the number of glass wool from the market point of view: As the thickness, you have to consider in all round, so your choice is the right one.

- Q: Glass wool products can be used for insulation layer

- Glass wool can be anti-aging effect is great

- Q: Does anyone clearly know about the construction technology of glass wool blanket, aluminum net and sound-absorbing wall?

- 1, the technological process: A layer of dry-laid asphalt felt→ wooden keel installation → install gypsum board → stick glass wool blanket → pave and nail a layer of glass fiber cloth→install aluminum net → fix aluminum net. 2. operation key points of construction methods, embed errosion prevention wooden bricks: During masonry construction, embed corrosion prevention wood bricks (40 × 60 × 60) while laying bricks, with horizontal distance of 400 to 500, and the vertical dimension of 400. I hope my answer can help you.

Send your message to us

Glass Wool Refractory Material Ceramic Fibre Blanket for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords