Glass Wool Reinforced Concrete Fireplace Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

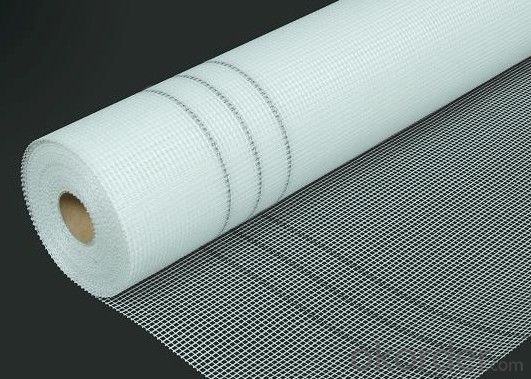

| Place of Origin: | Henan China (Mainland) | Brand Name: | cnbm | Model Number: | 145gsm 1m*50m 5mm*5mm |

| Application: | Wall Materials | Weight: | 145gsm | Width: | 1m-2m |

| Mesh Size: | 5mm*5mm | Weave Type: | Twill Woven | Yarn Type: | C-Glass |

| Alkali Content: | Medium | Standing Temperature: | 500 | Fiber Glass Mesh item No.: | FG5X5-145 |

| Logo printing: | Available | Fiber Glass Mesh label: | price included | OEM: | Available |

| Fiber Glass Mesh feel quality: | Soft and stiff | Alkali-resistant property: | Excellent | Fiber Glass Mesh tensile strength: | Excellent |

| Samples: | Free | Fiber Glass Mesh Delivery time: | Very fast | Trade Assurance: | 100% payment refund |

Packaging & Delivery

| Packaging Details: | PVC bag or Shrink package as inner package, then loaded into Carton or Pallet |

| Delivery Detail: | Within 20 days after receipt of down payment |

is mainly alkali-resistant fiberglass fabric, it made of the C or E glass fiber yarn (main ingredient is a silicate,

good chemical stability) through a special weaving technique, then coated by the anti-alkali and reinforcing agent and treated by high temperature heat finishing. It’s ideal engineering material in construction and decoration industry!

Main characteristics:

1.Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemical corrosion resistant, and strong resin bonding, soluble in styrene.

2.Outstanding process :Include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after 28-day immersion of 5% Na(OH) solution, so that guarantee high strength, high tensility, light weight.

3.Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it own 20% extra strength and beauty surface than normal fiberglass yarn!

4.Strength retention rate > 90%, elongation <1%, the durability of more than 50 years< span="">

5.Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property..

6.Good impact resistance and not easy to be teared.

7.Fire resistant, thermal insulation, sound insulation, insulations etc.

Fiber Glass Application:

1.Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board,gypsum board, bitumen etc)

2.Reinforced cement products.

3.Used for Granite, mosaic, marble back mesh etc.

4.Waterproof membrane fabric, asphalt roofing.

5.Framework material for reinforced plastics, rubber products,.

6.Fire board

7.Grinding wheel base fabric.

8.Road surface with geogrid

9.Construction caulking tape etc.

Fiber Glass Specifications:

1.16x16 mesh, 15x14 mesh, 12x12 mesh, 10x10 mesh, 9x9 mesh, 8x8 mesh, 6x6 mesh, 5x5 mesh, 5x4 mesh, 4x4 mesh, 3x3 mesh, 2.5x2.5 mesh, 1x1 mesh and so on

2.Weight/sq.meter: 40g—800g

3.Each roll length: 10m,20m,30m,50m—300m

4.Width: 1m—2.2m

5.Color: White (standard) blue, green, orange, yellow and others.

6.We can produce many specifications and use different packaging according to customers’ requests.

- Q: What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q: Are rubber and plastic thermal insulation material and glass wool in air conditioner energy-saving materials ?

- They are energy-saving materials. But glass wool has been banned.

- Q: What is the density of high-temperature glass fiber

- Density: Roll glass wool felt is coiled materials for large area coverage. It is not only thermal-insulating, but also can reduce shock and absorb sound,especially the medium and low frequency noise. It can help reduce the noise and improve the working environment.

- Q: what is the quota of glass wool rigid section of thermal insulation.

- Now, I also encountered the same problem, lz, can you tell me what quota should be used?

- Q: whether the sound insulation is asbestos good or the glass wool good?

- glass wool has good sound insulation, and it is commonly used in studio, bar, KTV, etc.

- Q: What are the uses of glass wool thermal insulation materials?

- Thermal insulation construction materials

- Q: What is the difference between quartz wool and glass wool?

- It belongs to quartz fiber. Quartz fiber is a cotton-shaped fiber made up of high purity silicon dioxide and natural quartz crystal. Its purity is 99.95% purity and density is 2.2g / cm3. The tensile strength is 7GPa and the tensile modulus is 70GPa. It has heat resistance, corrosion resistance and softness. At high temperatures, it remains high retention rate, stable dimension, good thermal shock resistance, chemical stability, transparency and electrical insulation. Filament with a diameter of 4 to 10μm can be used for reinforcing. Fiber?diameter of quartz wool depends on use, which in general is about 0.7 to 10μm. Manufacturing methods: (1) Drawing with melting quartz rod or pipe oxy-hydrogen flame, and then jetting it with oxy-hydrogen flame blowpipe to make into quartz wool with a diameter of 0.7 to 1 μ m; (2) Quartz is made into short fibers and the mats with high speed airflow before being melted with flame; (3) Making quartz fibers or rods go through oxy-hydrogen flame or coal gas flame at a constant velocity for the sake of softening them and then drawing them into filaments at a high speed. It is mainly used as the reinforcement of electrical insulating materials, thermal insulating materials and composite materials. It serves as the radome of aircraft nose, the exhaust nozzle of rockets, ablative materials of spacecraft and thermal insulation materials and so on. Glass wool is categorized into glass fiber, which is a manmade inorganic fiber. Glass wool is a material which fibering melting glass to form cottony shape. Its chemical composition belongs to the classification of glass, being an inorganic fiber. So, it is good shaped with small volume density, low thermal conductivity, good thermal insulation and sound absorption properties, great corrosion resistance as well as stable chemical performance.

- Q: How about the quoted price of asphalt glass wool felt?

- The sound absorption property of glass?wool?board is related to veneer materials, cavity and cavity's size, the thickness of glass wool board and apparent?density. Test shows that sound absorption property of glass wool board is mostly related to the thickness of board.

- Q: Which is the more commonly used thermal insulation material between thermal insulation glass?silk wool and rock wool?

- Glass wool: Glass wool has no shots, having less dust and little irritation to skin and respiratory system as well as light weight, able to be processed to products with long length based on design requirements. It entails less waste, easy to construction. It uses amorphous cellulose which is soft and lathy with no shots, able to serve for more than 20 years. So, in terms of price per ton, rock wool is cheaper than glass wool. But in terms of price per square meter, the prices of glass wool and rock wool are basically flat. If various factors like effect, construciton, service life, safety and bearing structure are took into account comprehensively, glass wool then is more economical. Rock wool: It contains a high content of shots and much dust. It is high irritable to skin and respiratory system, keeping heavy weight, so it cannot be processed for a long time. It entails much waste, difficult to construction. It uses crystalline fiber, which has a high content of shots, is shoyt and unstable. If used for a certain time, its shots and short?fiber will sink, making it unable to maintain a uniform shape, which will seriously affect the insulation effect and needs to be replaced consequently. And the replacement cycle is shorter than 10 years.

- Q: What is the uses of aluminum foil glass wool felt?

- Roll glass wool felt is coiled materials for large area coverage. It is not only thermal-insulating, but also can reduce shock and absorb sound,especially the medium and low frequency noise. It can help reduce the noise and improve the working environment. This material can be tailored based on the actual needs, mainly used for architectural indoor, muffler systems, transportation, refrigeration equipment, damping, sound absorption, noise reduction for the household appliances. Glass wool felt overlaid with aluminum foil has strong thermal radiation resistance. It is good lining material for high temperature workshops, control room, inner walls of machine room,compartment and flat top.

Send your message to us

Glass Wool Reinforced Concrete Fireplace Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords