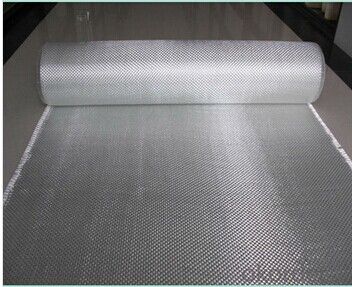

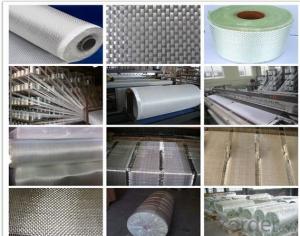

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

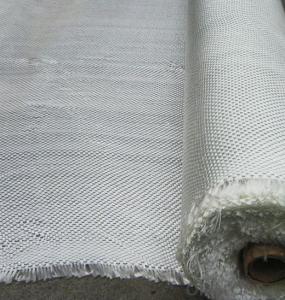

1.Glass woven roving are bidirectional fabric made by direction roving in plain weave pattern.

2.Compatible with unsaturated polyester ,vinyl resin ,epoxy resin .

3.Applicable for hand lay-up ,winding and compress molding process ,suitable for manufacturing tank ,boat ,automobile parts ,and other FRP product

Products advantage

1.Consistent thickness and excellent surface treatment .

2.Rapid impregnating and good compatibility with resin.

3.Uniform tension , high dimensional stability and easy to operate.

4.Good mechanical properties and high strength

5.Factory produce and product ISO certificated

1 Muti-resin-compatible

2 Easy shape adaptation

3 Easy impregnation

4 Good transparency

5 Excellent mechannical properties

product code | area weight | density warp*weft | tex | combustible content |

EWR200 | 200 | 4.6*4.6 | 200*200 | 0.4-0.8 |

EWR 270 | 270 | 4.6*4.1 | 300*300 | |

EWR360 | 360 | 3.2*1.8 | 600*900 | |

EWR400 | 400 | 3.6*3.2 | 600*600 | |

EWR450 | 450 | 3.2*2.8 | 600*900 | |

EWR500 | 500 | 2.2*2.0 | 1200*1200 | |

EWR580 | 580 | 2.6*2.2 | 1200*1200 | |

EWR600 | 600 | 2.6*2.4 | 1200*1200 | |

EWR800 | 800 | 2.0*1.6 | 2400*2400 |

- Q: Can glass fiber textiles be used in socks or stockings?

- Certainly, socks or stockings can utilize glass fiber textiles. These textiles, also known as fiberglass fabrics, possess lightweight characteristics, strength, and exceptional thermal insulation properties. They are frequently employed in various industries such as aerospace, automotive, and construction due to their durability and resistance to heat and chemicals. Regarding socks or stockings, glass fiber textiles can offer numerous advantages. Primarily, the thermal insulation properties of glass fibers aid in keeping feet warm during cold weather conditions. This feature proves particularly beneficial for individuals who spend significant time outdoors or in colder environments. Furthermore, the strength and durability of glass fibers render them suitable for incorporation into socks or stockings. They can endure repeated use, stretching, and washing without losing their shape or integrity. Consequently, glass fiber textiles can provide long-lasting and dependable support for the feet. Additionally, glass fiber textiles are commonly utilized in products that necessitate moisture-wicking properties, such as sportswear or outdoor gear. Moisture-wicking fabrics assist in drawing sweat away from the skin, thereby keeping the feet dry and impeding the growth of bacteria and odors. Hence, integrating glass fiber textiles into socks or stockings can enhance overall foot comfort and hygiene. However, it is crucial to note that direct contact with glass fibers can cause skin irritation. To address this concern, manufacturers often encase the glass fibers in a protective coating or blend them with other materials to create a comfortable and safe textile. Consequently, when utilizing glass fiber textiles in socks or stockings, it is imperative to ensure that the fibers undergo proper treatment to minimize any potential discomfort or irritation. In conclusion, glass fiber textiles can indeed be utilized in socks or stockings to provide thermal insulation, durability, and moisture-wicking properties. Nonetheless, it is essential to consider comfort and safety by employing properly treated fibers or blending them with other materials to ensure a pleasant wearing experience.

- Q: What are the different coating options for glass fiber textiles?

- The selection of coating options for glass fiber textiles depends on the intended application and desired characteristics. There are several choices available: 1. Silicone Coating: These coatings, based on silicone, are well-liked for their remarkable heat resistance, flexibility, and water repellency. They give the glass fiber textiles a smooth and glossy finish, making them suitable for insulation, fireproofing, and protective clothing. 2. Polyurethane Coating: Polyurethane coatings provide enhanced abrasion resistance, durability, and chemical resistance. They act as a protective barrier against moisture, oils, and chemicals, making them perfect for industrial aprons, conveyor belts, and outdoor covers. 3. PTFE Coating: PTFE coatings are famous for their non-stick properties, high temperature resistance, and low friction. These coatings create a smooth and non-porous surface on the glass fiber textiles, making them suitable for release sheets, conveyor belts, and insulation tapes. 4. Acrylic Coating: Acrylic-based coatings offer good UV resistance, flexibility, and moisture resistance. They are commonly used for outdoor applications such as awnings, canopies, and outdoor furniture covers. 5. Vinyl Coating: Vinyl coatings provide excellent weather resistance, flame retardancy, and chemical resistance. They are commonly used for applications requiring durability and protection against harsh environmental conditions, such as truck covers, tents, and tarps. 6. Latex Coating: Latex-based coatings offer good flexibility, adhesion, and water resistance. They are often used for applications such as gloves, medical textiles, and waterproof garments. When selecting the appropriate coating option, it is important to consider the specific requirements and intended use of the glass fiber textiles.

- Q: Are glass fiber textiles lightweight?

- Yes, glass fiber textiles are lightweight.

- Q: Can glass fiber textiles be used for making insulation blankets or wraps?

- Glass fiber textiles offer a range of applications in insulation. They possess exceptional thermal insulation properties and are widely utilized across multiple industries for insulation purposes. These textiles effectively resist heat due to their composition of fine glass fibers that trap air and minimize heat transfer. Their versatility allows for the insulation of pipes, ducts, tanks, and other equipment to prevent heat loss or gain. Furthermore, they exhibit resistance to moisture and provide acoustic insulation. Their lightweight, flexible, and durable nature further enhances their suitability for insulation in various settings. However, it is crucial to exercise caution when handling glass fiber textiles, as they may cause skin, eye, and respiratory irritation if not adequately protected.

- Q: Can glass fiber textiles be used in electrical insulation?

- Glass fiber textiles, due to their high electrical resistance, are capable of being utilized in electrical insulation. They are recognized for their exceptional dielectric properties, effectively impeding the passage of electric current and ensuring insulation and shield against electrical shocks. Moreover, glass fiber textiles possess non-conductive properties and exhibit commendable thermal stability, allowing them to endure elevated temperatures while maintaining their insulating capabilities. These attributes render glass fiber textiles a dependable option for electrical insulation across multiple industries, encompassing electronics, telecommunications, power generation, and the automotive sector.

- Q: Can glass fiber textiles be used in the production of protective gloves?

- Yes, glass fiber textiles can be used in the production of protective gloves. Glass fiber textiles are known for their high strength and heat resistance properties, making them suitable for applications where protection from cuts, abrasions, and heat is required.

- Q: How do glass fiber textiles affect supply chain logistics?

- Glass fiber textiles can have a positive impact on supply chain logistics by improving efficiency and reducing costs. These textiles are lightweight, durable, and non-corrosive, making them ideal for packaging and transportation purposes. They can protect products from damage during transit, reducing the risk of breakage or spoilage. Additionally, glass fiber textiles can be easily cleaned and reused, eliminating the need for frequent replacements and reducing waste. Overall, the use of glass fiber textiles in supply chain logistics can streamline operations, enhance product safety, and contribute to a more sustainable and cost-effective supply chain.

- Q: How do glass fiber textiles resist static electricity?

- Glass fiber textiles resist static electricity due to their non-conductive nature. The structure and composition of glass fibers prevent the accumulation and flow of electric charges, thereby minimizing the generation of static electricity.

- Q: Are glass fiber textiles resistant to solvents or cleaning agents?

- Glass fiber textiles, in general, display resistance to solvents and cleaning agents. The remarkable attributes of glass fiber, including its high tensile strength and durability, contribute to its ability to withstand a wide array of chemicals. Industries like automotive, aerospace, and chemical processing commonly employ glass fiber textiles due to the frequent exposure to solvents and cleaning agents. Nevertheless, it is crucial to acknowledge that the level of resistance to solvents and cleaning agents may vary depending on the specific type of glass fiber and the composition of the solvent or cleaning agent. Therefore, it is always recommended to consult the manufacturer's specifications or perform a compatibility test before subjecting glass fiber textiles to a particular solvent or cleaning agent.

- Q: How does glass fiber textile perform in terms of light transmission?

- Glass fiber textiles perform exceptionally well in terms of light transmission. Due to the high transparency of glass fibers, they allow a significant amount of light to pass through them, making them an ideal choice for applications where light transmission is important. Glass fiber textiles are commonly used in various industries, such as construction, automotive, and aerospace, to create lightweight and durable materials that allow light to pass through them. This property of glass fiber textiles not only enhances the aesthetics but also provides functional benefits, such as effective light distribution and energy efficiency. Additionally, glass fiber textiles can be designed to have different levels of light transmission, allowing for customization based on specific requirements. Overall, glass fiber textiles are excellent in terms of light transmission, making them a versatile and preferred choice in many applications.

Send your message to us

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords