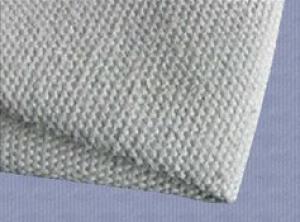

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Twisted Rope | Application: | Heat Insulation | Thickness: | 4-60mm |

| Width: | 4-60mm | Length: | 30m | Grade: | HA (High Aluminum) |

| Chemical Composition: | AL2O3+SIO2 | Ultimate Strength (≥ MPa): | 0.04 | Working Temperature: | 1260 |

| Fiber Diameter: | 2-5um | Thermal Conductivity: | 0.075-0.175 w/m.k | Shrinkage (1800℉, 3h): | <=-3 |

| Place of Origin: | China (Mainland) | Brand Name: | Model Number: | ceramic textile fiber rope | |

| Color: | White | fire-resistant rope density: | 600-620kg/m3 | ceramic rope: | ceramic rope braided |

| fire resistant rope: | ceramic textile fiber rope |

Packaging & Delivery

| Packaging Detail: | ceramic textile fiber rope package: carton with inner plastic bag |

| Delivery Detail: | 15days after receiving advance payment |

Production description of ceramic textile fiber rope

Iterm | Ceramic fiber ceramic rope twisted |

Type | Ceramic fiber ceramic rope twisted |

Ceramic fiber ceramic rope twisted | |

Ceramic fiber ceramic rope twisted | |

Characteristics | ** Good thermal insulation |

** Excellent high temperature strength | |

** Good electrical insulation properties | |

** High chemical stability | |

** Low thermal conductivity | |

Typical Use | Hightemperature pipe insulation and seal,cable insulation coating, flexible expansion joint connection,coke oven opening seal |

MOQ | 30m |

FOB Price | 4-6.5 USD/KG |

Port | Qingdao |

Payment Terms | L/C, D/A, D/P, T/T |

Packing | Carton with inner plastic bags |

Delivery | Within 15 days after delivery deposit |

Certificate | ISO9001, MSDS |

Product details of ceramic textile fiber rope

Type | Ref.No. | Reinforcement | Work. Temp (°C) | Density (kg/m3) | Size (mm) |

Twisted Rope | C101TG | Glass filament | 1260 | 600-620 | 6-40 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-40 | |

Round Braided Rope | C101TG | Glass filament | 1260 | 600-620 | 6-160 |

C101TS | Stainless steel wire | 1260 | 600-620 | 6-160 |

- Q: Can glass fiber textiles be used in medical applications?

- Glass fiber textiles have the capability to be used in medical applications. Renowned for their strength, durability, and resistance to chemicals, glass fiber textiles are appropriate for a range of medical uses. They find common employment in surgical gowns, drapes, and other protective clothing, as they effectively create a barrier against liquids and pathogens. Additionally, glass fiber textiles are utilized in wound dressings and bandages to provide support, facilitate wound healing, and allow for breathability. Moreover, they contribute to stability and reinforcement in prosthetics and orthotics. Nevertheless, it is essential to note that glass fiber textiles can potentially cause irritation or allergic reactions in certain individuals, necessitating cautious consideration when utilizing them in direct contact with the skin. All things considered, the distinctive properties and versatility of glass fiber textiles have proven advantageous in medical applications.

- Q: How do glass fiber textiles affect the drape of fabrics?

- Glass fiber textiles, also known as fiberglass textiles, can significantly affect the drape of fabrics. Due to their inherent stiffness and rigidity, fabrics that incorporate glass fiber textiles tend to have a stiffer and less fluid drape compared to fabrics without such reinforcements. The presence of glass fiber textiles adds structural integrity and strength to the fabric, making it more resistant to stretching and sagging. This can be beneficial in certain applications where durability and shape retention are crucial, such as upholstery fabrics, outdoor textiles, and industrial fabrics. However, the stiffness of glass fibers can also limit the natural flow and movement of the fabric. Fabrics with glass fiber textiles may lack the softness and suppleness that is desirable in clothing and drapery fabrics. They may feel less comfortable against the skin and restrict the freedom of movement of the wearer. It is worth noting that the impact on drape will vary depending on the amount and type of glass fiber textiles used, as well as the overall fabric construction. For instance, fabrics with a higher concentration of glass fibers or fabrics where the fibers are tightly woven or bonded may exhibit a more pronounced effect on drape. In conclusion, glass fiber textiles have a significant impact on the drape of fabrics, resulting in a stiffer and less fluid drape. While this can be advantageous in terms of durability and shape retention, it may also compromise the comfort and natural movement of the fabric, making it less suitable for certain applications such as clothing and drapery.

- Q: What are glass fiber textiles made of?

- Glass fiber textiles are made from fine strands of glass, known as glass fibers, that are woven together to create a strong and durable fabric.

- Q: Can glass fiber textiles be printed?

- Yes, glass fiber textiles can be printed. Glass fiber textiles are versatile materials that can be printed using various techniques such as screen printing, digital printing, and transfer printing. These printing methods allow for the application of designs, patterns, or images onto the glass fiber textiles, enhancing their aesthetic appeal and functionality. The printing process may require specific inks or dyes that are compatible with glass fibers to ensure proper adhesion and colorfastness. Additionally, it is important to consider the specific properties of glass fiber textiles, such as their heat resistance and durability, during the printing process to achieve the desired results.

- Q: How are glass fiber textiles used in the automotive industry?

- Due to their exceptional properties and versatility, glass fiber textiles find extensive usage in the automotive industry. These textiles, commonly referred to as fiberglass textiles, comprise finely woven strands of glass fibers, creating a fabric-like material. In the automotive industry, glass fiber textiles serve as primary components in the production of composite materials for diverse parts. These textiles are frequently employed as reinforcement materials in composite components, including body panels, hoods, bumpers, and interior parts. By providing superior strength and stiffness to the composites, the glass fibers make them lighter and more durable compared to conventional materials like steel or aluminum. Glass fiber textiles also play a crucial role in thermal insulation within automotive applications. They are utilized in engine compartments, exhaust systems, and underbody shields, effectively minimizing heat transfer and enhancing overall vehicle performance. Their exceptional thermal resistance properties make them an ideal choice for these high-temperature environments. Additionally, glass fiber textiles are utilized in the production of acoustic insulation materials to reduce noise in vehicles. They can be found in areas such as door panels, headliners, and carpeting, where they absorb and dampen sound vibrations, resulting in a quieter and more comfortable ride. Besides these applications, glass fiber textiles are employed in the automotive industry to reinforce rubber and plastic parts, such as hoses, gaskets, and seals. By providing additional strength and durability, they extend the lifespan and enhance the performance of these components. Overall, glass fiber textiles play a critical role in the automotive industry by offering lightweight, strong, and versatile materials for various applications. Manufacturers find them appealing due to their properties, as they allow for improved performance, safety, and efficiency in vehicles.

- Q: Can glass fiber textile be used in tents for extreme weather conditions?

- Yes, glass fiber textile can be used in tents for extreme weather conditions. Glass fiber is a strong and durable material that is resistant to harsh weather elements such as wind, rain, and snow. It provides excellent insulation and is capable of withstanding extreme temperatures. Additionally, glass fiber is lightweight and flexible, making it a suitable choice for tent construction in challenging weather conditions.

- Q: Can glass fiber textiles release harmful fibers?

- Improper manufacturing, handling, or maintenance of glass fiber textiles can result in the release of harmful fibers. These textiles are created by drawing molten glass into thin fibers, which can then be woven or knitted. If these fibers are damaged during production, installation, or use, they can break down into smaller particles or fibers that may become airborne and pose health risks when inhaled. The primary concern with glass fiber textiles is the release of respirable fibers, which are very small and can deeply penetrate the lungs. Inhaling these fibers can irritate the respiratory system and cause issues like coughing, wheezing, and shortness of breath. Prolonged exposure to high levels of glass fiber dust or fibers can even lead to more severe health conditions, such as lung scarring or cancer. To mitigate the risk of harmful fiber release, it is crucial to follow proper handling procedures and use suitable personal protective equipment when working with glass fiber textiles. Manufacturers should ensure the fibers are securely bound within the textile and regularly conduct quality control checks to identify any defects or damages that could result in fiber release. Additionally, regularly maintaining and cleaning glass fiber textiles can prevent the accumulation of dust and fiber particles, thereby reducing the potential for harmful fiber release. In conclusion, while glass fiber textiles have the potential to release harmful fibers if mishandled or damaged, adhering to proper manufacturing, handling, and maintenance practices can minimize the risk and ensure the safety of those working with or exposed to these materials.

- Q: Can glass fiber textile be printed on?

- Yes, glass fiber textile can be printed on. The process of printing on glass fiber textile involves applying ink or dye onto the surface of the textile using various printing techniques such as screen printing, digital printing, or heat transfer printing. However, it is important to note that due to the smooth and non-absorbent nature of glass fiber, special inks or dyes and printing techniques may be required for successful printing. These specialized materials and techniques ensure proper adhesion and long-lasting prints on glass fiber textiles.

- Q: Are glass fiber textiles fire-resistant?

- Yes, glass fiber textiles are fire-resistant.

- Q: What are the applications of glass fiber textile?

- Glass fiber textiles possess distinctive properties, making them applicable in various industries. Consider the following key uses of glass fiber textiles: 1. Composites reinforcement: Glass fiber textiles are extensively utilized as reinforcements in composite materials. They are integrated into plastic or resin matrices to enhance the final product's strength, stiffness, and durability. This renders them ideal for implementation in automotive components, aerospace parts, and construction materials. 2. Insulation: Glass fiber textiles exhibit exceptional thermal insulation properties, making them suitable for implementation in buildings, industrial equipment, and appliances. They effectively minimize heat transfer, prevent energy loss, and offer fire resistance. Common applications of glass fiber insulation include wall insulation, pipe insulation, and HVAC systems. 3. Filtration: The high porosity and retention efficiency of glass fiber textiles make them suitable for use in various filtration systems. They efficiently eliminate particulate matter from air or liquids, making them ideal for air filters, water filters, and oil filters. Industrial processes, automotive engines, and HVAC systems commonly utilize glass fiber filters. 4. Electrical Insulation: Glass fiber textiles possess superior electrical insulation properties and can withstand high temperatures. They function as insulation materials in electrical cables, transformers, and motors. To provide insulation and safeguard against electrical breakdown, conductors are wrapped with glass fiber textile tapes or fabrics. 5. Textile reinforcement: Glass fiber textiles can be blended with other fibers, such as cotton or polyester, to enhance the strength and durability of textile materials. This makes them suitable for application in sportswear, protective clothing, and upholstery fabrics. 6. Geotextiles: Within civil engineering and construction projects, glass fiber textiles can serve as geotextiles. They fulfill reinforcement, erosion control, and separation functions. Road construction, embankments, retaining walls, and landfills commonly employ glass fiber geotextiles. In conclusion, glass fiber textiles are versatile materials with a wide range of applications across various industries. Their unique properties render them desirable for reinforcement, insulation, filtration, electrical insulation, textile reinforcement, and geotextile applications.

Send your message to us

Seal Ceramic Glass Fiber Textile Fiber Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords