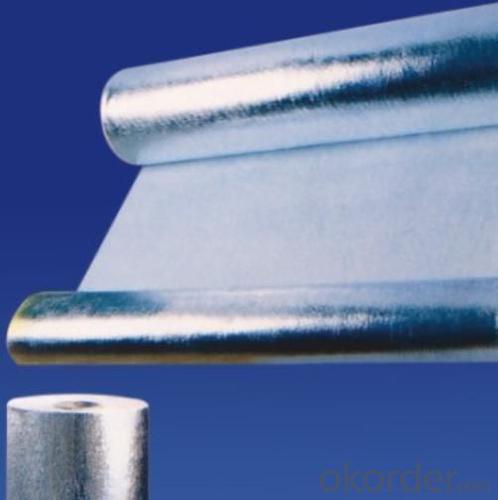

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info of E- Glass Fiber Fabric Laminated with Aluminum Foil

Dimension/Size

1). Roll width: 48mm, 58mm

2). Roll Length: 28m,

3). Core I. D.: 3"(76mm+/-1)

Packing:Regular Package

Standard:1000m*50m

Origin:China

Product Desciption

E- Glass Fiber Fabric Laminated with Aluminum Foil was made from aluminium Foil combine Fiberglass Mesh Fabric with polyethylene. As a hot stamping foil, It is used to intalled to ceiling by heat, Insulation Batts, Radiant Barriers, Covering Ducts and Pipes.

1. Intended to supply reflection but with lighter weight

Alumium Foil + Fiberglass Mesh Fabric + PE---thermal/heat/themol sensitive adhesive sheeting/facings/finish

2. Construction & Benefits:

Details of structure was list in table.

With fiberglass mesh cloth (25mesh, 31g/sqm ) as lining made this product light but strong enough.

Apply high reflective foil as exposed face, 18mircon thick supply stronger tensile strength.

Application of E- Glass Fiber Fabric Laminated with Aluminum Foil:

Widely used in wall/floor surface reinforcement in the building preventing from wall cracks and ceiling cracks and also barrier moisture / vapor / radiant / light in cover of roof, wall, pipe, air duct, glasswool, glass fiber mat as son on.

- Q: Can glass fiber textiles be used in the marine industry?

- Yes, glass fiber textiles can be used in the marine industry. Glass fiber textiles, also known as fiberglass, are widely used in the marine industry due to their excellent properties such as high strength, durability, corrosion resistance, and light weight. These textiles are commonly used in the construction of boat hulls, decks, and other components. Glass fiber textiles offer several advantages in the marine industry. Firstly, they have a high strength-to-weight ratio, which means they provide a great balance between strength and weight, making them suitable for various applications. This property helps to improve fuel efficiency and increase the speed of boats and ships. Additionally, fiberglass is highly resistant to corrosion, which is a crucial characteristic considering the constant exposure to saltwater in the marine environment. Another advantage of using glass fiber textiles in the marine industry is their durability. These textiles are resistant to impacts, moisture, and UV radiation, ensuring that they can withstand harsh marine conditions and maintain their structural integrity for a long time. Furthermore, fiberglass can be easily molded into complex shapes, allowing manufacturers to create custom designs and optimize the performance of marine vessels. In conclusion, glass fiber textiles are extensively used in the marine industry due to their exceptional properties. Their high strength, durability, corrosion resistance, and lightweight make them an ideal choice for various applications in boat and ship construction.

- Q: Are glass fiber textiles suitable for automotive interiors?

- Yes, glass fiber textiles are suitable for automotive interiors. They are known for their strength, durability, and resistance to heat, making them ideal for use in car interiors. Glass fiber textiles can be used for various purposes such as seat covers, carpeting, headliners, and door panels, providing excellent insulation and enhancing the overall aesthetics of automotive interiors.

- Q: Can glass fiber textiles be used in outdoor furniture?

- Indeed, outdoor furniture can utilize glass fiber textiles. Renowned for their robustness, resilience, and ability to withstand various environmental elements like UV rays, dampness, and fluctuating temperatures, glass fiber textiles are well-suited for outdoor applications. Moreover, their lightweight nature facilitates effortless mobility and transportation. One can employ glass fiber textiles as upholstery for outdoor cushions, as well as for encasing frames and structures in outdoor furniture.

- Q: Can glass fiber textiles be used for protective gear?

- Yes, glass fiber textiles can be used for protective gear. Glass fiber textiles, also known as fiberglass textiles, are materials made from fine fibers of glass. These textiles have several properties that make them suitable for protective gear applications. Firstly, glass fiber textiles have excellent strength and durability. They have high tensile strength, meaning they can withstand a great amount of pulling or stretching force without breaking. This property makes them ideal for protective gear, where the material needs to withstand external forces and provide reliable protection. Secondly, glass fiber textiles have high heat resistance. The melting point of glass fiber textiles is typically above 1000 degrees Celsius, which makes them suitable for applications where exposure to high temperatures is a concern, such as firefighting or industrial applications. Additionally, glass fiber textiles are lightweight and flexible, which allows for ease of movement and comfort when wearing protective gear. This is especially important in applications where the gear needs to be worn for extended periods. Furthermore, glass fiber textiles have good resistance to chemicals, corrosion, and UV radiation. This makes them suitable for applications where the gear needs to be resistant to various hazardous substances or environmental conditions. However, it is worth noting that glass fiber textiles can be irritating to the skin and respiratory system if the fibers become airborne and are inhaled or come into contact with the skin. Therefore, proper safety precautions, such as using appropriate protective clothing and equipment, should be taken when working with or wearing glass fiber textiles. In conclusion, glass fiber textiles can indeed be used for protective gear due to their strength, durability, heat resistance, lightweight and flexible nature, as well as their resistance to chemicals and UV radiation. However, it is important to ensure proper safety measures are in place to prevent any potential health risks associated with glass fiber textiles.

- Q: Can glass fiber textile be used in footwear?

- Yes, glass fiber textile can be used in footwear. It is a durable and lightweight material that can provide strength and stability to the structure of the footwear. Additionally, glass fiber textile can enhance the overall performance and support of the footwear, making it suitable for various sports and outdoor activities.

- Q: Are glass fiber textiles breathable?

- Glass fiber textiles are not breathable in the traditional sense. Unlike natural fibers such as cotton or wool, glass fiber textiles do not allow air to pass through easily. This is due to the nature of glass fibers, which are tightly woven and do not have the ability to absorb or release moisture like natural fibers do. As a result, wearing clothing or using products made from glass fiber textiles may cause discomfort and perspiration, as the fabric does not allow for proper ventilation.

- Q: Can glass fiber textile be used in thermal insulation?

- Glass fiber textiles, which are also known as fiberglass textiles, can be utilized for thermal insulation purposes. These textiles are crafted from delicate glass fibers that are woven into a fabric. Their outstanding thermal insulation properties stem from the low thermal conductivity of glass, enabling them to effectively trap and slow down the transfer of heat. Consequently, they are a suitable choice for thermal insulation applications. Building structures and houses often incorporate glass fiber textiles as insulation materials. They can be installed in walls, roofs, and floors to minimize heat loss or gain, thereby enhancing energy efficiency. Additionally, the fabric can be easily tailored and shaped to suit various areas, making it a versatile solution for insulation needs. Apart from their thermal insulation capabilities, glass fiber textiles offer a range of other advantages. They are non-combustible, resistant to moisture, and inhibit the growth of mold or mildew. These properties ensure their safety and durability for long-term use. Nevertheless, it is crucial to acknowledge that glass fiber textiles may cause irritation to the skin, eyes, and respiratory system. Appropriate precautions, such as donning protective clothing and masks, should be taken when handling and installing these textiles. Furthermore, it is advisable to consult professionals or adhere to manufacturer guidelines for the proper installation and maintenance of glass fiber textile insulation.

- Q: What are the disadvantages of using glass fiber textiles?

- Glass fiber textiles come with a range of drawbacks. Firstly, their cost is generally higher compared to other textile materials due to the complex production process and specialized equipment required. This can be problematic for those on limited budgets. Secondly, glass fiber textiles are prone to breakage and brittleness. Despite being known for their strength and durability, they can easily sustain damage from external forces or impacts. This restricts their use in applications where flexibility or resistance to bending is crucial. Another disadvantage relates to the potential health risks associated with glass fibers. During manufacturing, tiny glass particles can become airborne and inhaled, posing a threat to workers' respiratory systems. Prolonged exposure to these fibers can result in lung diseases such as fibrosis or even lung cancer. Therefore, it is essential to take proper safety precautions, such as wearing protective masks, when working with glass fiber textiles. Furthermore, glass fiber textiles have poor resistance to high temperatures. They tend to lose their structural integrity and strength when exposed to extreme heat. This hinders their usability in industries like aerospace or automotive, where heat resistance is critical. Lastly, glass fiber textiles exhibit relatively low resistance to UV radiation. Prolonged exposure to sunlight can cause the fibers to degrade, leading to discoloration and weakened strength. This presents a significant drawback in applications where the textiles are exposed to outdoor conditions or direct sunlight. In conclusion, despite their strengths and durability, glass fiber textiles have several disadvantages to consider, including high cost, brittleness, potential health risks, poor heat resistance, and low resistance to UV radiation. These factors should be taken into account when deciding whether to utilize glass fiber textiles in different applications.

- Q: What are the different types of glass fiber textiles available in the market?

- There are several types of glass fiber textiles available in the market, including woven fabrics, non-woven fabrics, knitted fabrics, and braided fabrics. Each type has its own unique characteristics and is used for various applications such as reinforcement in composites, insulation, and filtration.

- Q: Can glass fiber textile be used in 3D printing?

- Yes, glass fiber textile can be used in 3D printing. It is often combined with other materials, such as thermoplastics, to enhance the strength and durability of printed objects. The glass fiber reinforcement adds stiffness and resistance to deformation, making it suitable for applications that require high mechanical performance.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords