Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Micropore Insulation Board ,Heat Insulation materials

| Type: | Other Heat Insulation Materials | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | HCS | Color: | white | Apparent Density: | 220 +/- 10% |

| Heat Conductivity: | 0.060 | Highest Working Temperature: | 1050 | Material: | Xonotlite and reinforced glass fiber |

Packaging & Delivery

| Packaging Details: | Standard Fumigation Wooden pallet or Carton Package with Plastic Sheet inside |

| Delivery Detail: | Generally within 2 weeks after receipt of deposit |

Specifications

Microporous calcium silicate insulation board

experienced manufacturer

Size:1000*600mm,600*150mm

ISO9001:2008

Microporous calcium silicate insulation board

It is mixed with Xonotlite and reinforced glass fibre with high service temp. (1050 celsius),good heat insulation, low bulk density, high strength, good durability and so on.

Product characteristics:

² Good durability, can bear high temperature within the limit of continuous heat load,

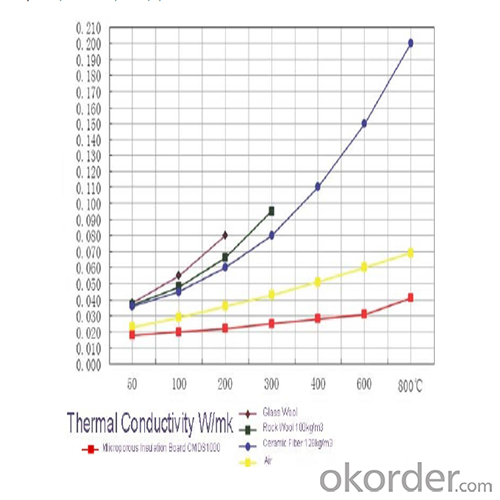

² Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

² Light weight, high strength. It is the highest in these hard thermal insulation products.

² Better durability, use for a long time without powder.

² Construction with ordinary carpenter applicability, tools can be optional cut products.

² Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

² Fear water, but after drying also can be used.

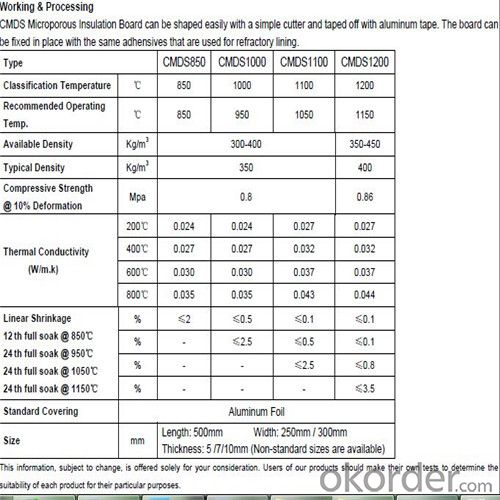

HCS Physical Performance Index

Items | Unit | HCS-170 | HCS-220 | HCS-270 |

Bulk Density | Kg/m3 | 170(±10%) | 220(±10%) | 270(±10%) |

Pressure Strength | MPa | ≥0.40 | ≥0.50 | ≥0.60 |

Flexural Strength | MPa | ≥0.30 | ≥0.35 | ≥0.40 |

Thermal Conductive | W/m.k | ≤0.048 +0.00011t | ≤0.050 +0.00011t | ≤0.056 +0.00011t |

Temp. limit | degrees | 1000 | 1050 | 1050 |

Linear Shrinkage | % | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) | ≤1.50 (1000,3hrs) |

Block Sizes and Dimensional Tolerances

Length(±3mm) | Width(±3mm) | Thickness(+2mm,—1.5mm) |

610 | 303,300,150 | 25—140 |

600 | 300 | 25—140 |

400 | 250 | 25—140 |

1000 | 500 | 25—140 |

1200 | 600 | 25—140 |

We also supply special size and type.

Standard Dimension:

1000(900)×600(500)×5-20mm

We can also manufacture the special dimensions as customers need.

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available for us.

Q5:After an order is confirmed,when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Thanks for your coming in,if there is any question,I will be glad to help you.

- Q: How do glass fiber textiles affect insulation?

- Glass fiber textiles are commonly used in insulation due to their excellent thermal properties. The presence of glass fibers in textiles enhances insulation by creating a network of air pockets that trap heat and prevent its transfer. This helps to reduce heat loss or gain, making the space more thermally efficient. Additionally, glass fibers have a low thermal conductivity, meaning they do not readily conduct heat, further improving the insulation performance. Overall, glass fiber textiles positively impact insulation by providing effective thermal resistance and contributing to energy savings.

- Q: Can glass fiber textiles be used in surgical implants?

- Yes, glass fiber textiles can be used in surgical implants. Glass fiber textiles are known for their high strength, biocompatibility, and resistance to corrosion, making them suitable for various medical applications including surgical implants. They can provide structural support and enhance the stability of implants while promoting tissue integration, making them a viable option in the field of surgical implantation.

- Q: Can glass fiber textile be used in solar panels?

- Yes, glass fiber textile can be used in solar panels. Glass fiber textile is a lightweight and flexible material that possesses excellent electrical insulation properties. It can be used as a substrate or backing material in solar panels to provide structural support and protection to the delicate solar cells. The use of glass fiber textile in solar panels helps to enhance their durability, as it offers resistance to weathering, moisture, and UV radiation. Additionally, the flexibility of glass fiber textile allows for easier integration into various solar panel designs, enabling greater flexibility in installation options. Therefore, glass fiber textile is a suitable material for use in solar panels and contributes to their overall efficiency and longevity.

- Q: Are glass fiber textiles resistant to breaking under tension?

- Yes, glass fiber textiles are highly resistant to breaking under tension. They possess exceptional tensile strength due to the inherent properties of glass fibers, making them highly durable and capable of withstanding significant stress without breaking.

- Q: Can glass fiber textiles be used for insulation in buildings?

- Yes, glass fiber textiles can be used for insulation in buildings. Glass fiber textiles are a popular choice for insulation due to their excellent thermal and acoustic properties. They are made from fine strands of glass, which are woven into a fabric or formed into mats or boards. These textiles are lightweight, flexible, and easy to install, making them suitable for various applications in buildings. Glass fiber textiles have a high resistance to heat transfer, making them effective in reducing heat loss or gain through walls, floors, and roofs. They can help maintain a comfortable indoor temperature, reduce energy consumption, and lower heating and cooling costs. Additionally, glass fiber textiles have good sound-absorbing qualities, which can contribute to noise reduction and create a more peaceful environment within buildings. Another advantage of using glass fiber textiles for insulation is their non-combustible nature. Unlike some other insulation materials, glass fiber textiles do not burn, making them a safe choice for building applications. They are also resistant to mold, mildew, and pests, ensuring a healthier indoor environment. Glass fiber textiles are available in various forms, such as blankets, batts, rolls, and loose-fill, allowing for easy installation in different building components. They can be used in walls, ceilings, floors, and attics, providing thermal and acoustic insulation throughout the entire building. Overall, glass fiber textiles are a versatile and effective option for insulation in buildings. Their thermal performance, sound absorption capabilities, fire resistance, and ease of installation make them a popular choice for both residential and commercial construction projects.

- Q: Can glass fiber textile be used in acoustic panels?

- Yes, glass fiber textile can be used in acoustic panels. Glass fiber textiles are known for their sound-absorbing properties, making them an ideal material for acoustic panels. They can help reduce echo, reverberation, and unwanted noise in various settings such as recording studios, theaters, and offices.

- Q: Can glass fiber textiles be used in the packaging industry?

- Yes, glass fiber textiles can be used in the packaging industry. They are often utilized to reinforce and strengthen packaging materials, providing improved durability and protection for the products being packaged. Additionally, glass fiber textiles can also enhance the fire resistance properties of packaging, making them suitable for industries where fire safety is essential.

- Q: Are glass fiber textiles resistant to abrasion?

- Glass fiber textiles have a general resistance to abrasion. They are produced by weaving strands of glass fibers, which are widely recognized for their exceptional strength and durability. These textiles find frequent use in contexts that prioritize protection against abrasion, such as in protective clothing, industrial fabrics, and reinforcement materials. The robust and inflexible characteristics of glass fibers enable them to endure rubbing or scraping against various surfaces without succumbing to wear or fraying easily. As a result, glass fiber textiles are highly favored within industries that demand materials possessing superb resistance to abrasion.

- Q: How does glass fiber textile compare to other textile materials?

- Fiberglass fabric, also known as glass fiber textile, provides numerous benefits in comparison to alternative textile materials. Firstly, it boasts exceptional durability and a longer lifespan than many other textiles. It withstands wear and tear and can endure extreme temperatures, rendering it suitable for a diverse array of uses. Furthermore, glass fiber textile is renowned for its remarkable strength-to-weight ratio. It surpasses steel in terms of strength when considering weight, making it a favored choice in industries where both strength and lightness are vital, such as aerospace and automotive manufacturing. This strength also facilitates the production of thin and lightweight fabrics, enhancing versatility and ease of use. Another advantage of glass fiber textile lies in its resistance to chemicals and environmental factors. It is non-flammable and does not easily degrade when exposed to harsh chemicals, making it suitable for environments where other textiles may prove unsuitable. Moreover, glass fiber textile exhibits excellent insulation properties, both for heat and sound. It serves as an effective insulator in applications like insulation jackets, curtains, and blankets due to its poor conductivity of heat. Additionally, it aids in reducing noise pollution owing to its sound-absorbing properties. However, glass fiber textile does possess certain limitations. It lacks the flexibility of other textile materials, potentially restricting its use in applications that require high flexibility. Additionally, the sharpness of glass fibers can irritate and harm the skin, necessitating proper handling and protective measures when working with glass fiber textiles. In conclusion, glass fiber textile presents a host of advantages over alternative textile materials, encompassing durability, strength, resistance to chemicals and extreme temperatures, as well as insulation properties. Despite its limitations, its unique qualities make it an invaluable material in various industries and applications.

- Q: Can glass fiber textiles be used for reinforcement in plastic bottles?

- Indeed, plastic bottles can be reinforced with glass fiber textiles. Commonly known as fiberglass, these materials are lightweight, sturdy, and long-lasting, and are widely utilized in various industries such as automotive, aerospace, and construction. By incorporating glass fiber textiles into plastic bottles, their structural integrity is enhanced, minimizing the risk of deformation or breakage. The glass fibers contribute strength and stiffness to the plastic matrix, thereby increasing the bottles' resistance to impact, pressure, and temperature fluctuations. Moreover, the use of glass fiber reinforcement can reduce the amount of plastic needed in the bottle's production, presenting a more sustainable alternative. However, it is important to acknowledge that the addition of glass fibers may slightly affect the bottle's transparency, resulting in a slight opacity. Consequently, if transparency is crucial, alternative reinforcement materials like carbon fiber or aramid fibers may be preferred.

Send your message to us

Glass Fiber Reinforced Microporous Calcium Silicate Insulation Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords