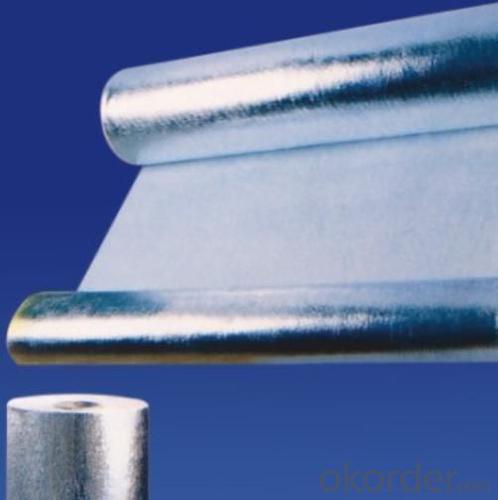

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info of E- Glass Fiber Fabric Laminated with Aluminum Foil

Dimension/Size

1). Roll width: 48mm, 58mm

2). Roll Length: 28m,

3). Core I. D.: 3"(76mm+/-1)

Packing:Regular Package

Standard:1000m*50m

Origin:China

Product Desciption

E- Glass Fiber Fabric Laminated with Aluminum Foil was made from aluminium Foil combine Fiberglass Mesh Fabric with polyethylene. As a hot stamping foil, It is used to intalled to ceiling by heat, Insulation Batts, Radiant Barriers, Covering Ducts and Pipes.

1. Intended to supply reflection but with lighter weight

Alumium Foil + Fiberglass Mesh Fabric + PE---thermal/heat/themol sensitive adhesive sheeting/facings/finish

2. Construction & Benefits:

Details of structure was list in table.

With fiberglass mesh cloth (25mesh, 31g/sqm ) as lining made this product light but strong enough.

Apply high reflective foil as exposed face, 18mircon thick supply stronger tensile strength.

Application of E- Glass Fiber Fabric Laminated with Aluminum Foil:

Widely used in wall/floor surface reinforcement in the building preventing from wall cracks and ceiling cracks and also barrier moisture / vapor / radiant / light in cover of roof, wall, pipe, air duct, glasswool, glass fiber mat as son on.

- Q: Can glass fiber textiles be used in reinforcement of bamboo fibers?

- Yes, glass fiber textiles can be used in the reinforcement of bamboo fibers. The combination of glass fiber textiles and bamboo fibers can result in a composite material that possesses enhanced mechanical properties. Glass fibers are known for their high strength and stiffness, while bamboo fibers are lightweight and have good flexibility. By reinforcing bamboo fibers with glass fiber textiles, the resulting material can have improved tensile strength, flexural strength, and impact resistance. This combination can be particularly useful in applications where both strength and flexibility are required, such as in the construction industry for beams, columns, and other structural elements. Additionally, the use of glass fiber textiles can also provide better dimensional stability and resistance to moisture, further enhancing the overall performance of the composite material.

- Q: What are some common applications of glass fiber textiles?

- Some common applications of glass fiber textiles include reinforcement materials in composites, insulation for buildings and pipelines, protective clothing and equipment, filtration systems, and electrical insulation.

- Q: Can glass fiber textiles be used as insulation?

- Yes, glass fiber textiles can be used as insulation. They are often used in applications such as thermal insulation for buildings, pipes, and appliances due to their excellent thermal resistance properties. Glass fiber textiles can effectively trap air and reduce heat transfer, making them a popular choice for insulation materials.

- Q: Can glass fiber textiles be recycled?

- Yes, glass fiber textiles can be recycled. Glass fiber textiles, also known as fiberglass, are made from a combination of glass fibers and resins. When these textiles reach the end of their lifespan or are no longer needed, they can be broken down and processed to extract the glass fibers. These fibers can then be used to make new products, such as insulation materials, reinforcement for composites, or even new glass fiber textiles. Recycling glass fiber textiles helps reduce waste and conserves resources, making it a sustainable choice for the textile industry.

- Q: Can glass fiber textiles be laminated?

- Yes, glass fiber textiles can be laminated. Lamination is a common process that involves bonding multiple layers of materials together using an adhesive. Glass fiber textiles can be laminated with other materials to enhance their strength, durability, and other properties.

- Q: Can glass fiber textiles be used in carpeting?

- Yes, glass fiber textiles can be used in carpeting.

- Q: How do glass fiber textiles perform in terms of dimensional stability?

- Glass fiber textiles are known for their excellent dimensional stability. This means that they are resistant to changes in size or shape when subjected to external forces or environmental conditions. The unique composition of glass fibers, being made from molten glass that is drawn into thin strands, provides them with inherent strength and rigidity. As a result, glass fiber textiles retain their shape and size even under extreme temperatures, moisture, or mechanical stress. The dimensional stability of glass fiber textiles can be attributed to their low thermal expansion coefficient. This means that they do not expand or contract significantly when exposed to heat or cold, making them suitable for applications that require precise dimensions. Additionally, glass fibers have high tensile strength, which means they can resist stretching or elongation when subjected to pulling forces. This characteristic further contributes to their dimensional stability. Glass fiber textiles also exhibit good resistance to moisture absorption, which helps prevent swelling or shrinkage when exposed to humidity or water. This is particularly important in applications where dimensional accuracy is critical, such as in the construction of composite materials or reinforcement in structures. Overall, glass fiber textiles offer exceptional dimensional stability, making them a preferred choice in industries such as aerospace, automotive, construction, and marine. Their ability to maintain their size and shape under various conditions ensures reliable performance and longevity in demanding applications.

- Q: How do glass fiber textiles perform in terms of water repellency?

- Glass fiber textiles are renowned for their exceptional ability to repel water. Their intrinsic characteristics prevent water absorption and make them highly resistant to moisture. As a result, glass fiber textiles are perfectly suited for situations that demand water repellency, including outdoor clothing, tents, and umbrellas. Moreover, glass fiber textiles possess excellent resistance to mildew and mold, further augmenting their water repellency. In summary, glass fiber textiles excel in terms of water repellency, offering a robust and dependable solution for diverse industries and consumer goods.

- Q: How do glass fiber textiles resist puncturing?

- Glass fiber textiles resist puncturing due to their unique properties and construction. Firstly, glass fiber textiles are made from fine strands of glass fibers that are woven together to form a strong and durable fabric. These fibers are incredibly thin, typically less than a tenth the diameter of a human hair, which allows for a high density of fibers in the fabric. This high density provides a strong barrier against punctures. Additionally, glass fibers are known for their high tensile strength. Tensile strength refers to the ability of a material to resist pulling forces without breaking. Glass fibers have an exceptional tensile strength, which means they can withstand a significant amount of force without tearing or puncturing. Furthermore, glass fiber textiles are often coated with a protective layer or resin. This coating further enhances their resistance to puncturing. The coating acts as an additional barrier, increasing the fabric's durability and preventing sharp objects from penetrating the surface. Moreover, glass fiber textiles are known for their excellent dimensional stability. This means that they do not stretch or shrink when subjected to external forces. This property helps to maintain the fabric's integrity and prevents it from weakening or tearing, even under stress. Overall, the combination of the fine strands of glass fibers, high tensile strength, protective coating, and excellent dimensional stability make glass fiber textiles highly resistant to puncturing. They offer a reliable and durable solution for applications that require protection against sharp objects or potential punctures.

- Q: How do glass fiber textiles affect worker safety?

- Glass fiber textiles can have both positive and negative impacts on worker safety. On the positive side, these textiles are known for their excellent heat resistance properties, making them suitable for use in high-temperature environments. They can effectively protect workers from heat-related risks, such as burns and thermal radiation. Additionally, glass fiber textiles have high tensile strength, which can provide protection against cuts and abrasions, minimizing the risk of injuries. However, there are also potential safety concerns associated with glass fiber textiles. Glass fibers can be sharp and brittle, leading to skin irritation and respiratory issues if they come into contact with the skin or are inhaled. Workers handling glass fiber textiles should therefore be provided with appropriate personal protective equipment (PPE), such as gloves, masks, and safety glasses, to mitigate these risks. Furthermore, the manufacturing process of glass fiber textiles involves the use of chemicals and high temperatures, which can present hazards if not properly controlled. Employers must ensure proper ventilation, training, and monitoring to prevent exposure to harmful substances and minimize the risk of accidents. Overall, glass fiber textiles can enhance worker safety in certain applications, such as high-temperature environments, but they also require careful handling and appropriate safety measures to mitigate potential risks.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Glass Fiber Textiles - E-Glass Fiber Fabric Laminated with Aluminum Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords