Glass Fiber Textile Epoxy Glass Cloth Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Laminate Type ◆ 3240 G10 G11 FR-4 FR-5 ◆ Thickness:0.5mm-90mm ◆ Size:1000×1200mm 1000×2000mm 1000×2400mm Rod/Tube Type ◆ 3721 3722 3723 3724 3725 3840 3841 3520 3526 3640 ◆ Diameter:6mm 8mm 10mm-200mm ◆ Length:1000mm | |

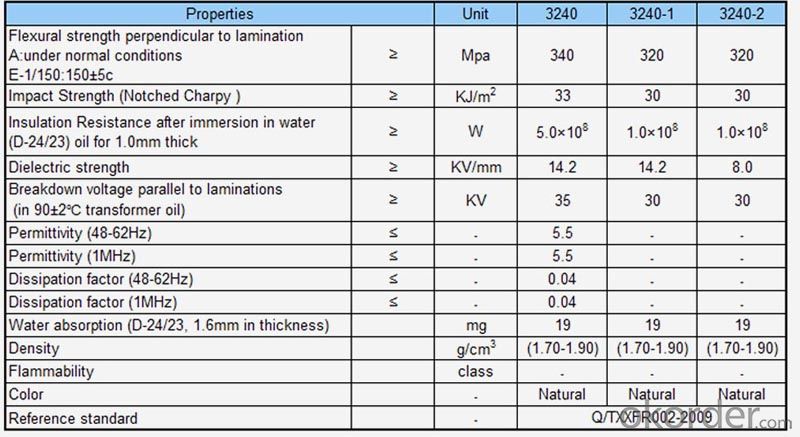

| 3240 * Temperature grade: B glass (130℃) * Color: nature, red, green, black * Thickness: 0.5-80mm * Size: 1020x2040mm | 3240-1 & 3240-2 * Temperature grade: B glass (130℃) * Color: nature,yellow * Thickness: 0.5-80mm * Size: 1020x2040mm |

| |

| F880A F881A * Temperature grade: B glass (130℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 | F882A F883A * Temperature grade: F glass (155℃) * Color: nature, green * Thickness: 0.5-80mm * Size(mm): 1020x1220 1020x2040 1220x2470 |

- Q: Can glass fiber textiles be used for making shoes or footwear?

- Glass fiber textiles have the potential to be utilized in the production of shoes or footwear. These textiles possess qualities such as being lightweight, robust, and enduring, making them an excellent choice for a variety of purposes, including footwear. The incorporation of glass fiber textiles in shoes can contribute to reinforcing and stabilizing the shoe's structure, thereby enhancing both comfort and durability. Additionally, the utilization of glass fiber textiles can improve the shoes' breathability and ability to wick away moisture, creating a pleasant and dry environment for the feet. Nevertheless, it is crucial to acknowledge that glass fiber textiles may not possess the same level of flexibility or stretchability as other commonly employed footwear materials. Consequently, careful consideration and thoughtful design would be necessary to ensure that the shoes maintain a comfortable fit and the desired degree of flexibility.

- Q: How do glass fiber textiles affect thermal comfort?

- Glass fiber textiles can have a significant impact on thermal comfort. These textiles are known for their excellent insulation properties, which help to regulate heat transfer. They have a low thermal conductivity, meaning they are effective at reducing the transfer of heat between the body and the surrounding environment. Glass fiber textiles also have the ability to trap air within their fibers, creating a layer of insulation. This trapped air acts as a buffer, reducing heat loss and increasing thermal comfort. The insulation provided by glass fiber textiles can help to maintain a comfortable body temperature in cold environments, as it prevents the body heat from escaping and keeps the cold air from penetrating. Furthermore, glass fiber textiles can also help to enhance thermal comfort in hot environments. They have the ability to reflect and block a significant amount of solar radiation, thereby reducing the amount of heat absorbed by the body. This can help to keep the body cool and prevent overheating. In addition to their insulation properties, glass fiber textiles are also breathable and moisture-wicking. This means that they can effectively manage moisture and perspiration, allowing the body to stay dry and comfortable. This is particularly important during physical activities or in humid environments, as it helps to prevent the build-up of moisture on the skin that can lead to discomfort. Overall, glass fiber textiles play a crucial role in enhancing thermal comfort. Their insulation properties, ability to reflect heat, breathability, and moisture-wicking capabilities all contribute to maintaining a comfortable body temperature in a variety of environmental conditions.

- Q: Can glass fiber textiles be used for reinforcement purposes?

- Yes, glass fiber textiles can be used for reinforcement purposes.

- Q: Do glass fiber textiles shrink or stretch?

- Glass fiber textiles do not shrink or stretch. Glass fibers are incredibly strong and do not have the elasticity to stretch. Additionally, glass fibers do not have the ability to shrink like some natural fibers do when exposed to heat or moisture. Therefore, glass fiber textiles will maintain their shape and size, making them a durable and reliable material for various applications.

- Q: Can glass fiber textiles be washed?

- Glass fiber textiles can indeed be washed, but it is crucial to adhere to the washing instructions and suggestions provided by the manufacturer. Unlike other fabrics, glass fiber textiles tend to be more fragile, hence it is advisable to utilize a gentle cycle and mild detergent during the washing process. It is further advised to steer clear of employing bleach or fabric softeners, as these substances can inflict harm on the fibers. Subsequent to washing, it is imperative to handle the textiles with caution and permit them to dry naturally.

- Q: How do glass fiber textiles perform in extreme weather conditions?

- Glass fiber textiles are known for their excellent performance in extreme weather conditions. These textiles are made from fine strands of glass, which are woven together to create a strong and durable fabric. This unique composition gives glass fiber textiles several advantages when it comes to withstanding harsh weather. Firstly, glass fiber textiles have a high resistance to temperature fluctuations. They can withstand both extreme heat and cold without undergoing any significant structural changes. This makes them suitable for applications in both desert-like environments and freezing conditions. Secondly, glass fiber textiles are highly resistant to moisture. Unlike natural fibers such as cotton or wool, glass fibers do not absorb water. This means that they do not become weakened or distorted when exposed to rain, snow, or high levels of humidity. Glass fiber textiles are also resistant to mold and mildew growth, making them ideal for use in damp or humid climates. Glass fiber textiles also have excellent resistance to UV radiation. They do not degrade or lose their strength when exposed to sunlight for prolonged periods. This makes them highly suitable for outdoor applications where exposure to the sun's rays is common, such as awnings, canopies, or outdoor furniture. Furthermore, glass fiber textiles possess exceptional strength and durability. They have a high tensile strength and are resistant to tearing, abrasion, and punctures. This makes them capable of withstanding strong winds, storms, and other extreme weather events without suffering damage or degradation. In summary, glass fiber textiles excel in extreme weather conditions due to their resistance to temperature fluctuations, moisture, UV radiation, and their overall strength and durability. These properties make them a reliable choice for various applications, ranging from outdoor furniture and awnings to protective clothing and industrial materials.

- Q: Can glass fiber textiles be used for insulation in buildings?

- Glass fiber textiles are a great choice for insulating buildings. They have excellent thermal and acoustic properties, making them popular for insulation. They are made from fine strands of glass that are woven into fabric or formed into mats or boards. These textiles are lightweight, flexible, and easy to install, making them suitable for many building applications. Glass fiber textiles are very effective at reducing heat loss or gain through walls, floors, and roofs. They can help maintain a comfortable indoor temperature, reduce energy consumption, and lower heating and cooling costs. They also absorb sound well, which can create a peaceful environment in buildings. One advantage of using glass fiber textiles for insulation is that they do not burn, unlike some other materials. This makes them a safe choice for building applications. They are also resistant to mold, mildew, and pests, which ensures a healthier indoor environment. Glass fiber textiles come in different forms, such as blankets, batts, rolls, and loose-fill, allowing for easy installation in various building components. They can be used in walls, ceilings, floors, and attics, providing insulation throughout the entire building. In conclusion, glass fiber textiles are a versatile and effective option for insulation in buildings. Their thermal performance, sound absorption capabilities, fire resistance, and ease of installation make them a popular choice for residential and commercial construction projects.

- Q: How does glass fiber textile perform in terms of durability?

- Glass fiber textile is known for its exceptional durability. It has high tensile strength, meaning it can withstand heavy loads and resist tearing or breaking. Additionally, glass fiber textile is highly resistant to chemicals, moisture, and UV radiation, making it suitable for both indoor and outdoor applications. Its durability allows it to maintain its structural integrity and appearance over time, ensuring long-lasting performance in various environments.

- Q: Are glass fiber textiles resistant to oil and grease?

- Yes, glass fiber textiles are resistant to oil and grease. Glass fibers are hydrophobic in nature, meaning they repel water and other liquids, including oil and grease. This makes glass fiber textiles highly resistant to oil and grease, making them suitable for various applications where contact with these substances is expected. The non-porous surface of glass fibers prevents oil and grease from penetrating the fabric, allowing for easy cleaning and maintenance. Additionally, glass fiber textiles offer excellent thermal resistance, mechanical strength, and chemical resistance, making them a popular choice in industries such as automotive, aerospace, and industrial manufacturing, where oil and grease exposure is common.

- Q: Can glass fiber textile be used in soundproofing?

- Yes, glass fiber textiles can be used in soundproofing. Glass fiber textiles are known for their excellent sound absorption properties due to their high density and ability to trap sound waves. When used as insulation or in the form of acoustic panels, glass fiber textiles can effectively reduce the transmission of sound through walls, floors, and ceilings. They are commonly used in buildings, studios, theaters, and other spaces where soundproofing is required. Additionally, glass fiber textiles are lightweight, easy to install, and have fire-resistant properties, making them a popular choice for soundproofing applications.

Send your message to us

Glass Fiber Textile Epoxy Glass Cloth Products

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 800 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords