Glass Fiber and Ceramic Fiber Textiles for Refractory Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | (Mainland) | Application: | Refractory | Model Number: | LBR11110904 |

| Brand Name: | Color: | pure white | Working Temperature: | 1100-1350 | |

| Grade: | ST(STANDARD) | Length: | 30000mm | Density: | 500kg/m3 |

| Width: | 10-150mm | Thickness: | 2-10mm | Fiber diameter: | 3um |

Packaging & Delivery

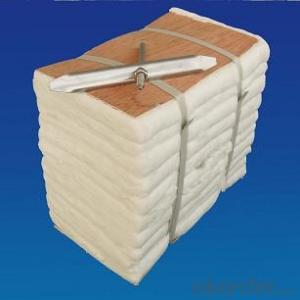

| Packaging Detail: | Wrapped by plastic bag inside,protected by carton box outside. |

| Delivery Detail: | 15 days after deposit |

Specifications

Ceramic Fiber Tape:

1.Glass-fiber reinforced;

2.Environmental-Friendly;

3.Easy to use;

4.Harmless to human.

Characteristics

Good compression strength.

Non-toxicity, environmental protection.

Low thermal conductivity and low thermal capacity.

Good antacid oil resistance and water vapor resistance.

Ceramic Fiber Textile

The Product Description

Ceramic fiber textile includes Ceramic fiber cloth, strap, twisted rope,

round straided rope and square straided rope.All are made from our high quality

ceramic fiber material. They can be used for high temperature applications up to

2300°F. The rope is reinforced with fiberglass filament, and optional Inconel/alloy

steel wire. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount

of binder material which is normally burned at lower temperature and does not affect

the insulation property.

The three different styles are designed to fit different application needs: twisted rope

is a soft rope, while square and round braid are more dense .

Application

Common applications :door seals or caulking for ovens, furnaces and boilers,

expansion joints, cable or pipe wrapping, high temperature seals or gaskets.

widely used in welding, foundry works, aluminum and steel mills, boiler insulation

and seal, exhaust systems, shipyards, refineries, power plants and chemical plants.

We also provide many other refractory and insulation materials, so if you have demands

about them, pls contact us.

Technical data

Item | Cloth | Tape | Round rope | Square rope | Twisted Rope(Yarn) | Twisted rope(wool top) |

Classification Temp °C | 1260 | |||||

Bulk Density kg/m3 | 500±30 | |||||

Organic Content | ≤15 | |||||

Working Temp | 450(Glassfiber Filament) | |||||

1000(Metal Wire ) | ||||||

Loss After Firing(800°C)% | 12±2 | 12±2 | 12±2 | 12±2 | 12±2 | 8-10 |

Size | 30mx1mx2 30mx1mx3 | widen10-120mm length30m | Φ6-50mm

| 20x20 | Φ6-50mm

| Φ6-50mm

|

Any question,pls feel to contact us!

- Q: How do glass fiber textiles affect manufacturing processes?

- Glass fiber textiles have a significant impact on manufacturing processes in various industries. These textiles, made from thin strands of glass, offer numerous benefits that enhance the efficiency, durability, and overall quality of manufacturing processes. One of the primary ways glass fiber textiles affect manufacturing processes is by providing strength and reinforcement. These textiles are known for their high tensile strength, allowing them to reinforce various materials and products. By incorporating glass fiber textiles into manufacturing processes, companies can create stronger and more durable end products. This is particularly important in industries such as automotive, aerospace, and construction, where strength and structural integrity are crucial. Glass fiber textiles also have excellent thermal insulation properties. They can withstand high temperatures without degrading, making them ideal for use in manufacturing processes that involve heat. By using glass fiber textiles as insulation, companies can protect their equipment and products from heat-related damage and improve energy efficiency in processes like heating, ventilation, and air conditioning (HVAC) systems. Furthermore, glass fiber textiles are highly resistant to chemicals, moisture, and corrosion. This makes them suitable for manufacturing processes where exposure to harsh substances or environmental conditions is common. For example, in the chemical processing industry, glass fiber textiles can be used as protective coatings or linings for equipment to prevent corrosion. In addition to their physical properties, glass fiber textiles are also lightweight and flexible. This makes them easy to handle and manipulate during manufacturing processes. They can be easily woven, molded, or laminated onto other materials, allowing for greater design flexibility and customization. This versatility enables manufacturers to create complex shapes and structures, leading to innovative and efficient manufacturing processes. Moreover, glass fiber textiles have excellent electrical insulation properties. They can effectively insulate against electrical current, making them suitable for use in electrical and electronic manufacturing processes. By incorporating glass fiber textiles into these processes, companies can ensure the safety and reliability of their electrical components and devices. Overall, glass fiber textiles play a crucial role in manufacturing processes by providing strength, thermal insulation, chemical resistance, flexibility, and electrical insulation. These properties enhance the quality, efficiency, and durability of products, making glass fiber textiles an essential material in various industries.

- Q: Can glass fiber textiles be used in solar panels?

- Yes, glass fiber textiles can be used in solar panels. They are often used as reinforcement materials in the manufacturing of solar panels, providing mechanical strength and durability to the panel structure. Additionally, glass fiber textiles can help improve the overall performance and reliability of solar panels by reducing the risk of mechanical failure and extending their lifespan.

- Q: Can glass fiber textile be used in spacecraft construction?

- Glass fiber textiles, also known as fiberglass, are a suitable material for constructing spacecraft. They are lightweight and have high tensile strength, making them ideal for various applications in the aerospace industry. In spacecraft construction, they are commonly used as reinforcement material in composite structures. Using glass fiber textiles in spacecraft construction has several advantages. Firstly, they possess excellent mechanical properties, including a high strength-to-weight ratio and stiffness. These properties are crucial for maintaining structural integrity and reducing the overall weight of the spacecraft. This is particularly important in the aerospace industry, where minimizing weight is a top priority to maximize fuel efficiency. In addition, glass fiber textiles offer good thermal and electrical insulation properties. This makes them suitable for applications that require temperature control and electrical isolation. Such properties are essential in spacecraft construction, as space's extreme temperatures and harsh environments can pose significant challenges to a spacecraft's integrity and performance. Moreover, glass fiber textiles are resistant to corrosion. This is beneficial in space, where exposure to different elements and harsh conditions can degrade materials over time. Their corrosion resistance helps extend the lifespan of spacecraft components, reducing the need for frequent repairs or replacements. Overall, glass fiber textiles provide a reliable and cost-effective solution for constructing spacecraft. They possess the necessary strength, lightweight, thermal insulation, and corrosion resistance properties required for the demanding conditions of space exploration.

- Q: Can glass fiber textiles be used in the electronics industry?

- Yes, glass fiber textiles can be used in the electronics industry. Glass fiber textiles, also known as fiberglass textiles, have excellent electrical insulation properties, making them suitable for various applications in the electronics industry. They are commonly used as insulation material in electronic components such as printed circuit boards (PCBs) and electrical cables. The high electrical resistance of glass fiber textiles helps prevent short circuits and ensures the safe and reliable functioning of electronic devices. Additionally, glass fiber textiles can also provide thermal insulation and mechanical strength to protect electronic components from heat, vibrations, and physical damage. Therefore, glass fiber textiles are widely used in the electronics industry to enhance the performance and durability of electronic devices.

- Q: Can glass fiber textiles be used for making sporting goods or equipment?

- Sporting goods or equipment can indeed be made using glass fiber textiles. These textiles, commonly referred to as fiberglass, are lightweight and possess a high strength-to-weight ratio, thus making them suitable for numerous sports applications. They find frequent use in the manufacturing of sports equipment such as tennis rackets, golf club shafts, hockey sticks, and fishing rods. The exceptional properties of glass fiber textiles, which include durability, flexibility, and resistance to moisture and corrosion, make them well-suited for enduring the rigorous demands of sporting activities. Moreover, these textiles can be shaped and designed in various ways, enabling manufacturers to produce customized and high-performance sporting goods. All in all, due to their outstanding mechanical properties and versatility, glass fiber textiles have become a favored choice within the sports industry.

- Q: How do glass fiber textiles resist heat transfer?

- Glass fiber textiles resist heat transfer due to the unique properties of the glass fibers themselves. Glass fibers have a low thermal conductivity, which means that they are not good conductors of heat. When heat is applied to the surface of the glass fiber textile, the fibers do not readily transfer the heat to other areas of the textile. This property helps to minimize the transfer of heat from one side of the textile to the other. Additionally, glass fibers have a high melting point, typically around 1500 degrees Celsius. This high melting point allows glass fiber textiles to withstand high temperatures without melting or degrading. Instead of melting, the glass fibers retain their structural integrity, which further contributes to their ability to resist heat transfer. Furthermore, glass fiber textiles can also have an added layer of insulation, such as an aluminum foil or ceramic coating. These coatings create a barrier that reflects heat radiation and prevents it from penetrating the textile. This added insulation enhances the heat resistance of the glass fiber textile, making it even more effective at resisting heat transfer. In conclusion, glass fiber textiles resist heat transfer through their low thermal conductivity, high melting point, and in some cases, added insulation. These properties make glass fiber textiles ideal for applications where heat resistance is required, such as in insulation materials, protective clothing, and fire-resistant barriers.

- Q: How do glass fiber textiles contribute to chemical stability?

- Glass fiber textiles contribute to chemical stability in several ways. Firstly, glass fibers are inherently resistant to chemical attack from a wide range of substances. Unlike organic fibers, such as cotton or polyester, glass fibers do not degrade or react chemically with most acids, bases, or solvents. This makes them an ideal choice for applications where chemical stability is essential. Additionally, glass fibers have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with changes in temperature. This property is crucial for chemical stability because it ensures that the structure of the textile remains intact even when exposed to extreme temperature variations. By maintaining its dimensional stability, glass fiber textiles can resist chemical degradation caused by thermal stress. Furthermore, glass fibers are non-combustible, meaning they do not burn or support combustion. This characteristic is crucial in chemical environments where fire hazards are present. By eliminating the risk of combustion, glass fiber textiles contribute to the overall chemical stability of a system. Moreover, glass fibers have excellent resistance to UV radiation, which is known to cause degradation in many materials. This UV resistance ensures that glass fiber textiles maintain their structural integrity and performance over extended periods of exposure to sunlight or other sources of UV radiation. Overall, the chemical stability of glass fiber textiles is a result of their inherent resistance to chemical attack, low coefficient of thermal expansion, non-combustible nature, and UV resistance. These properties make glass fiber textiles an excellent choice for applications where chemical stability is a critical requirement.

- Q: Can glass fiber textiles cause respiratory issues?

- Yes, glass fiber textiles can potentially cause respiratory issues. The tiny fibers in glass fiber textiles, when inhaled, can irritate the respiratory system and lead to discomfort, coughing, and difficulty breathing. Long-term exposure to these fibers may even result in more serious respiratory conditions such as fibrosis. It is important to take necessary precautions, such as wearing protective masks, while working with or around glass fiber textiles to minimize the risk of respiratory issues.

- Q: Can glass fiber textiles be used in tents and awnings?

- Yes, glass fiber textiles can be used in tents and awnings. They are commonly used due to their strength, durability, and resistance to weather conditions. Glass fiber textiles provide excellent insulation and protection against UV rays, making them suitable for outdoor applications such as tents and awnings.

- Q: Can glass fiber textiles be used in reinforcement of Kevlar fibers?

- Yes, glass fiber textiles can be used in reinforcement of Kevlar fibers.

Send your message to us

Glass Fiber and Ceramic Fiber Textiles for Refractory Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords