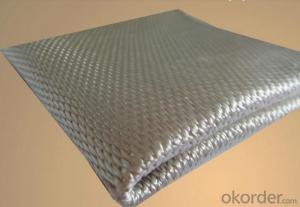

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Welding Pillow fiberglass fabric made

Welding pillow, fire resistance pillow, it is made of fiberglass

Description:

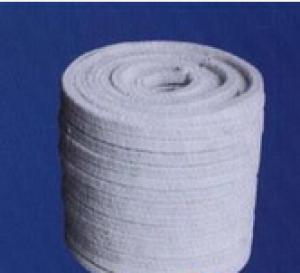

Welding pillow, fire resistance pillow, it is made of fiberglass and insert with glass wool or ceramic wool, sewing it into pillow, it is good welding products while need pillow shape fire resistance.

We can manufacture all kinds of welding pillor, fire resistance pillow as per customer request. Just contact our sales for details.

Outside Materials : fiberglass fabrics, Silica fabrics, heat treated fiberglass fabrics, silicone coated fiberglass fabrics, Ceramic fiber fabric, Carbonizedfiber fabrics, Aluminum coated fiberglass fabrics, Acrylic coated fiberglass fabrics.

Inside Materials: Glass fiber wool, ceramic fiber wool

Temperature resistance: 500 Deg. C . to 1000 Deg. C.

Size: as per customer request

- Q: Can glass fiber textiles be used in high-temperature applications?

- Yes, glass fiber textiles can be used in high-temperature applications. Glass fibers have excellent heat resistance properties and are commonly used in industries such as aerospace, automotive, and insulation where high temperatures are involved. They can withstand temperatures up to 1000°C without losing their structural integrity, making them suitable for various high-temperature applications.

- Q: Is glass fiber textile resistant to fire?

- Yes, glass fiber textile is resistant to fire.

- Q: Are glass fiber textiles suitable for medical and healthcare products?

- Glass fiber textiles, also called fiberglass textiles, offer numerous advantages that make them well-suited for medical and healthcare products. To begin with, glass fiber textiles possess exceptional chemical resistance, enabling their use in sterile environments like hospitals and clinics. They can endure exposure to various cleaning agents, disinfectants, and even strong medical chemicals without deteriorating or compromising their structural integrity. Furthermore, glass fibers are non-toxic and do not release any harmful substances, making them safe for employment in medical and healthcare products. This is particularly crucial in situations where patient safety is paramount, such as wound dressings, surgical drapes, and medical implants. Additionally, glass fiber textiles exhibit remarkable thermal insulation properties. They offer insulation against both heat and cold, which proves advantageous in medical applications where temperature control is critical, for instance, in incubators, thermal blankets, or packaging for temperature-sensitive items. Moreover, glass fibers are acknowledged for their high tensile strength and durability. They can withstand repeated use, washing, and sterilization without compromising their mechanical properties. This renders them ideal for products that require long-term durability, like bandages, medical gauze, or prosthetic devices. Furthermore, glass fiber textiles demonstrate a high level of dimensional stability, meaning they maintain their shape and size over time. This characteristic proves particularly beneficial in applications where precise measurements and fit are essential, such as compression garments or orthopedic supports. To conclude, glass fiber textiles are undeniably suitable for medical and healthcare products. Their resistance to chemicals, non-toxic nature, thermal insulation properties, durability, and dimensional stability make them highly valuable in various healthcare applications. They ensure the safety and comfort of patients while upholding stringent quality standards.

- Q: Can glass fiber textile be used in electrical applications?

- Glass fiber textiles are indeed suitable for electrical applications due to their durability and outstanding electrical insulation properties. Their ability to withstand high temperatures and resist chemicals makes them perfect for insulation materials like cables, wires, and circuit boards. The presence of glass fibers guarantees stability and strength, thus ensuring the safety and reliability of electrical components. Moreover, these textiles are utilized for electromagnetic shielding and grounding in electrical applications as well.

- Q: Can glass fiber textiles be used in the sports and recreation industry?

- Yes, glass fiber textiles can be used in the sports and recreation industry. They offer various benefits such as high strength, durability, and resistance to heat, chemicals, and weather conditions. Glass fiber textiles can be used in the production of sports equipment, such as skis, tennis rackets, and bicycles, as well as for manufacturing protective gear like helmets and body armor. They provide excellent performance characteristics and contribute to enhancing the safety and performance of athletes and recreational enthusiasts.

- Q: How are glass fiber textiles used in the marine industry?

- Glass fiber textiles are widely used in the marine industry for various purposes. One of the main applications is in boat building and repair. Glass fiber fabrics, commonly known as fiberglass, are used to reinforce the hulls, decks, and other structural components of boats and yachts. These textiles provide strength and durability, making the vessels more resistant to impacts and wear. Moreover, glass fiber textiles are used in the production of composite materials used in marine applications. By impregnating the fabric with resin, it can be molded into different shapes and forms, allowing for the creation of lightweight yet strong components like hulls, masts, and rudders. This composite material offers high strength-to-weight ratio, corrosion resistance, and excellent fatigue properties, making it ideal for the demanding marine environment. Glass fiber textiles also find use in the production of marine insulation materials. These textiles are used to manufacture insulation blankets, wraps, and jackets that are used to protect various equipment and piping systems on ships and offshore platforms. The thermal insulation properties of glass fiber textiles help to prevent heat loss or gain, ensuring the efficient operation of the marine equipment. Furthermore, glass fiber textiles are employed in the manufacturing of marine upholstery and interior linings. Fabrics made from glass fibers are resistant to moisture, UV radiation, and chemicals, making them suitable for marine upholstery applications. These textiles can withstand the harsh marine conditions and provide comfort and durability to the interiors of boats and yachts. In summary, glass fiber textiles play a crucial role in the marine industry. They are used for reinforcing boat structures, creating composite materials, providing insulation, and enhancing the aesthetics of marine vessels. Their strength, durability, and resistance to various environmental factors make them essential components in the construction, repair, and maintenance of boats and yachts.

- Q: Are glass fiber textiles resistant to abrasion?

- Yes, glass fiber textiles are generally resistant to abrasion due to their strong and durable nature.

- Q: Are glass fiber textiles resistant to chemicals used in swimming pools?

- Yes, glass fiber textiles are generally resistant to chemicals used in swimming pools. Glass fiber is known for its excellent chemical resistance, making it a suitable material for applications where exposure to chemicals is common, such as swimming pools. The resins used in glass fiber textiles are typically engineered to withstand the harsh environment of swimming pools, including chlorine, bromine, and other chemicals used for disinfection and water treatment. This chemical resistance allows glass fiber textiles to maintain their structural integrity and performance over time, even in the presence of these chemicals. However, it is important to note that the specific chemical composition and concentration of the pool water may vary, and it is advisable to consult with the manufacturer or supplier of the glass fiber textiles to ensure compatibility with the specific chemicals used in a particular swimming pool.

- Q: What are the different thickness options for glass fiber textile?

- The thickness options for glass fiber textiles can vary, but commonly range from thin and lightweight options such as 0.1mm to thicker and more durable options like 0.5mm or even thicker. The specific thickness chosen depends on the intended use and application of the glass fiber textile.

- Q: Can glass fiber textiles be used in insulation pipes?

- Yes, glass fiber textiles can be used in insulation pipes. Glass fiber textiles are commonly used as insulation material due to their excellent thermal insulation properties and resistance to high temperatures. They can effectively reduce heat transfer and prevent energy loss in pipes, making them suitable for insulation applications in various industries.

Send your message to us

Glass Fiber Textiles - Heat Insulation Refractory Welding Pillow Fiberglass Fabric 550C-1000C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords