Glass Fiber Textile Textured Fiberglass Sleeving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

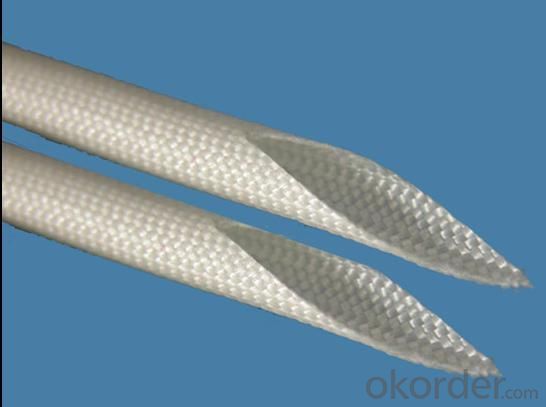

general infomation of Textured Fiberglass Sleeving

Textured fiberglass sleeving is braided by the textured fiberglass yarn without core. It can be used as fire protection of cable or wire covering.

Characteristics of Fiberglass Sleeving

Cost-efficient high temperature performance

Texturized Fiberglass Sleeve is a heavy wall braided glass fiber sleeve capable of operating at a continuous temperature of 1000F (538C). High bulk fiber construction gives excellent insulation properties, and the texturized, untreated construction allows Thermosleeve to exhibit excellent dielectric strength and resistance to thermal conductivity.

specification of Textured Fiberglass Sleeving

Inner diameter: 13mm-75mm (1/2"-3")

Thickness: 1.5mm-3mm (3/50"-1/8")

- Q: How do glass fiber textiles affect the breathability of fabrics?

- Glass fiber textiles can enhance the breathability of fabrics by providing better moisture management and increasing the airflow. These textiles have a high level of porosity, allowing air and moisture to pass through easily. This helps to regulate body temperature and prevent the build-up of sweat and humidity, making the fabric more comfortable to wear in various climates and activities.

- Q: Are glass fiber textiles resistant to discoloration in contact with sweat?

- Yes, glass fiber textiles are generally resistant to discoloration when in contact with sweat. Glass fibers are made from molten glass that is spun into fine strands, resulting in a material that is highly durable and resistant to various external factors, including sweat. Unlike natural fibers such as cotton or wool, glass fibers do not absorb sweat, which reduces the likelihood of discoloration or staining. Additionally, glass fiber textiles are often treated with protective coatings that enhance their resistance to discoloration even further. However, it is important to note that the specific composition and quality of the glass fiber textile can influence its resistance to discoloration, and some low-quality or poorly treated products may still be susceptible to staining over time.

- Q: Are glass fiber textiles resistant to water absorption?

- Yes, glass fiber textiles are generally resistant to water absorption. Glass fibers are made from molten glass which is then spun into fine strands. These strands are then woven or knitted together to form textiles. The glass fibers themselves are not porous, which means they do not allow water to pass through easily. This makes glass fiber textiles highly resistant to water absorption. Additionally, glass fibers are inherently non-hygroscopic, meaning they do not absorb moisture from the air. As a result, glass fiber textiles retain their structural integrity and do not become weakened or damaged when exposed to water or moisture. This makes them an ideal material for applications such as outdoor furniture, boat covers, and other products that require water resistance. However, it is important to note that while glass fibers themselves are resistant to water absorption, the textiles made from them may still have properties that can absorb water, such as the backing material or coatings used in the manufacturing process.

- Q: Are glass fiber textiles resistant to pilling?

- Glass fiber textiles are generally not prone to pilling. Pilling occurs when loose fibers on the surface of a fabric become tangled and form small balls or clusters. However, glass fiber textiles have a smooth and durable surface that prevents the formation of pills. This is because glass fibers are inorganic and do not have the same tendency to fray or break as natural or synthetic fibers. Additionally, glass fibers are often woven tightly, which further reduces the likelihood of pilling. Overall, glass fiber textiles are known for their excellent resistance to pilling, making them a popular choice for applications where durability and longevity are important factors.

- Q: How does glass fiber textile perform in terms of electrical conductivity?

- Glass fiber textile is known for its excellent electrical insulation properties. It is a non-conductive material and does not allow the flow of electric current. This makes it ideal for applications where electrical conductivity is not desired or can be hazardous, such as in electrical insulation for cables, wiring, and electronic components. Glass fiber textile is also resistant to high temperatures, moisture, and chemicals, further enhancing its electrical insulation performance. Overall, glass fiber textile has a high dielectric strength and low electrical conductivity, making it a reliable and safe choice for electrical insulation applications.

- Q: What is the durability of glass fiber textiles?

- Glass fiber textiles are known for their exceptional durability. They have a high tensile strength and are resistant to wear and tear, making them long-lasting and suitable for various applications. Additionally, they can withstand exposure to harsh environmental conditions, chemicals, and UV radiation without deteriorating, further enhancing their durability.

- Q: Can glass fiber textiles be used in insulation for pipes or ducts?

- Glass fiber textiles, like glass wool or fiberglass, possess outstanding thermal and acoustic insulation characteristics, which is why they are frequently utilized as insulation materials. These textiles are extensively employed in a wide range of settings, such as residential, commercial, and industrial, for insulating pipes and ducts. Their impressive resistance to heat transfer guarantees remarkable efficacy in minimizing energy loss and ensuring temperature regulation in pipes and ducts. Moreover, these textiles are lightweight, flexible, and simple to install, making them a highly favored option for insulation purposes.

- Q: Can glass fiber textiles be used in packaging?

- Yes, glass fiber textiles can be used in packaging. Glass fiber textiles are highly durable and have excellent strength properties, making them suitable for various packaging applications. They are commonly used in the manufacturing of protective packaging materials such as bags, wraps, and containers. Glass fiber textiles provide a high level of protection to the packaged goods, as they resist tearing, abrasion, and puncture. Additionally, they are resistant to moisture, chemicals, and UV radiation, making them ideal for packaging products that require a high level of protection during storage or transportation. Overall, glass fiber textiles offer a reliable and effective solution for packaging needs.

- Q: How do glass fiber textiles affect the moisture absorption or release of fabrics?

- Glass fiber textiles have a minimal effect on the moisture absorption or release of fabrics. Due to their low absorbency and moisture-wicking properties, they can help to enhance the breathability and moisture management of fabrics.

- Q: How do glass fiber textiles compare to natural fibers in terms of strength?

- Glass fiber textiles are generally stronger than natural fibers. Glass fibers have a higher tensile strength and are less prone to breakage or stretching compared to natural fibers such as cotton or silk. This makes glass fiber textiles ideal for applications requiring high strength and durability.

Send your message to us

Glass Fiber Textile Textured Fiberglass Sleeving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10 Tons kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords