Silica Fiber Textiles Basalt Fiber Cloth with Fireproof Function 108-1200gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Fiber Cloth Introduction

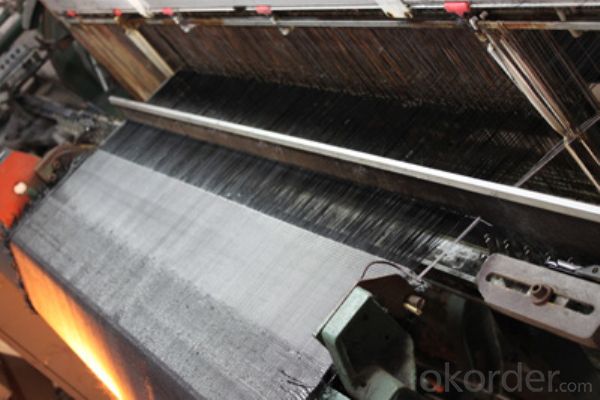

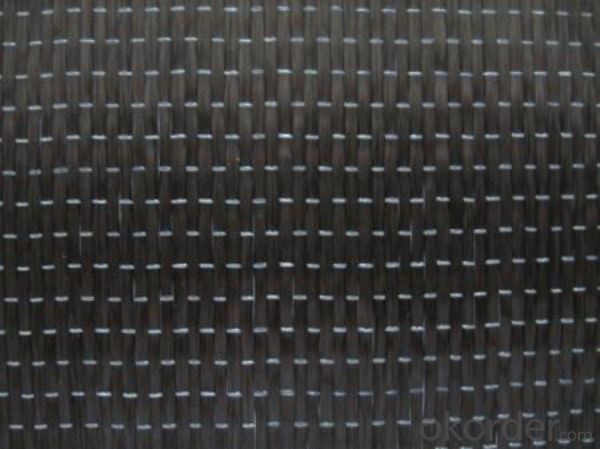

Continuous basalt fiber cloth is made by impregnating woven basalt fiber scrim with asphalt and then drying to be made.

In the normal temperature, the ratio of the elastic modulus between the basalt fiber concrete and the asphalt concrete is 24: 1.

Basalt fiber textile woven into the fiber grille, molded and dried after dipping treatment. The main role of the Basalt Mesh is to improve resistance to fatigue cracking, high temperature rutting, low temperature shrinkage crack, delaying reflective cracking, for cement mortar or concrete. Mainly used for reinforcement, filter and high temperature resistant.

Advantages of Basalt Fiber Cloth

Basalt fibre concrete has the excellent resistance to deformation, the elongation at break is about 3.1%. Basalt Fiber owns the high-temperature resistance, frost resisting resistance (-260~650 ℃), the same thermal expansion coefficient with the asphalt concrete, the high tensile strength, ultraviolet resistance, the stable chemical resistance, ageing resistance. The stirring temperature of the asphalt concrete is up to 190℃. The high-temperature Basalt fiber is the best alternative of the polyester fiber. It can satisfy the asphalt stirring temperature (190 ℃), and it is the excellent construction material for reinforced cement & concrete, and it has the outstanding penetration resistance.

Basalt textile/geotextile is more durable than metallic and glass-fiber reinforcement due to basalt fiber’s excellent performance.

Specifications of Basalt Fiber Cloth

Item no. | warp | weft | Density(inch) | Weight(gsm) | Thickness(mm) | Length/Roll |

WP105-1000 | 33Tex | 33Tex | 37.5×37.5 | 105 | 0.1 | |

WP180-1000 | 33Tex*2 | 33Tex*2 | 37.5×30 | 180 | 0.18 | 100 |

WP600-1000 | 600Tex | 600Tex | 12.2×12.2 | 600 | 0.6 | 50 |

WD250-1000 | 600Tex | 68Tex | 8.7×3.5 | 250 | 0.25 | 100 |

WD300-1000 | 600Tex | 68Tex | 12.3×3.5 | 300 | 0.3 | 100 |

Specification for part of satin basalt fiber cloth

Item no. | warp | weft | Density(inch) | Weight(gsm) | Thickness(mm) | Length/Roll |

W300-1000 | 33Tex*3 | 33Tex*3 | 45×30 | 300 | 0.3 | 100 |

W430-1000 | 33Tex*4 | 33Tex*4 | 40×35 | 430 | 0.4 | 100 |

Application of Basalt Fiber Cloth

Plain basalt fiber fabric is widely used in electrical appliances, electronics, transportation, chemical engineering, construction, fire control, environmental protection and the field of medical apparatus and instruments.

FAQ:

1. Which payment do you accept?

For you convinience, our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

4. When will you reply my request?

You are our expected customer, we’ll reply your request within 24hours. Please feel free to contact us at any time.

Photos

- Q: What are the differences between the two models of quartz microfiber filter paper QM-A and QM-H?

- According to the specific situation, to see which type you fit, the best advice Tianhong instrument professionals

- Q: What are the uses and characteristics of quartz fiber cloth?

- Performance: corrosion protection, buried in the ground, will not rot, stand in the air, will not be weathered, not afraid of water, not afraid of drying.

- Q: How much is Armani dermal quartz watch ar1647?

- See: pattern and pores should be the first to identify the leather, leather can be seen on the surface of natural pattern, the pores do exist, and the distribution is uneven, the opposite side section, level of animal fiber, recognizable, lower animal fibers, with fingernails scraping on the leather fiber will be erected, pile feeling a small amount of fiber, can also be dropped, and synthetic leather fabric can see the opposite side, no animal fiber, general skin without pores, but there are some imitation pores, there will be no obvious pores, some pattern is not clear, or have a regular pattern of artificial pores are quite consistent. Natural leather shape is irregular, thickness is not uniform, its surface is often more or less there are some natural defects, the surface smooth degree, General belly relaxation, full leather surface has obvious pores and patterns, leather in the general pile. Synthetic leather and uniform thickness, smooth surface, no natural pores and incomplete, the pattern is very uniform, the leather in general without pile.

- Q: Can fiber quartz heater regulate temperature?

- No way, because the inside of the silk, general skills are fixed

- Q: Can quartz watches be set with mobile phones and computers?

- Away from water and steam: watches are waterproof, and waterproof fittings may still loose over time, leading to moisture, rust, and loss of function, so they need to take off their watches when washing their hands or taking a bath.

- Q: How are quartz products made?

- How are quartz products made?

- Q: Want to buy a heater, check on the Internet, found that all kinds of heaters have their own advantages and disadvantages and applicability.I would like to ask: what are the advantages and disadvantages of carbon fiber tube heaters?Thank you

- At present, people still cannot be pumped into carbon fiber with carbon or graphite, with only some carbon containing organic fibers (such as nylon yarn, acrylic yarn, rayon, etc.) as raw materials, organic fiber and plastic resin together, on the rare gas atmosphere, under certain pressure under high heat carbonization of carbon fiber is carbon fibrous material, the chemical composition of carbon content of at least 90%. Since the elemental carbon can not be melted at high temperature (sublimation above 3800K) and is insoluble in various solvents, carbon fiber can not be made from carbon elements. Carbon fibers can be obtained by solid phase carbonization of high molecular organic fibers or by pyrolysis of low molecular hydrocarbons. At present, most of the carbon fibers produced in the world are made by solid phase carbonization of polyacrylonitrile fibers. The process is A pre oxidation: heated in air and maintained at 200-300 degrees for tens to hundreds of minutes.

- Q: Can quartz watches be set with mobile phones and computers?

- Watch collection: do not put in the pockets and purses, so as to avoid small cloth crumbs, dust into the watch, or perfume, cosmetics volatile oil, condensed water, resulting in parts of the watch corrosion oxidation. When not worn for a long time, it should be placed in a cool and dry box.

- Q: Don't know how Pang Ming fiberglass cloth cloth good or good and Heikki Haijibu quartz

- Ten. Sea cloth is regarded as a "wall paint partner" is a set of paint, wallpaper double effect as a whole.

Send your message to us

Silica Fiber Textiles Basalt Fiber Cloth with Fireproof Function 108-1200gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords