Glass Fiber Roving Assembled Multi End Fiberglass Roving for Gypsum Mouldings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber Roving Assembled Multi End Fiberglass Roving for Gypsum Mouldings

Introduction:

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

Packaging:

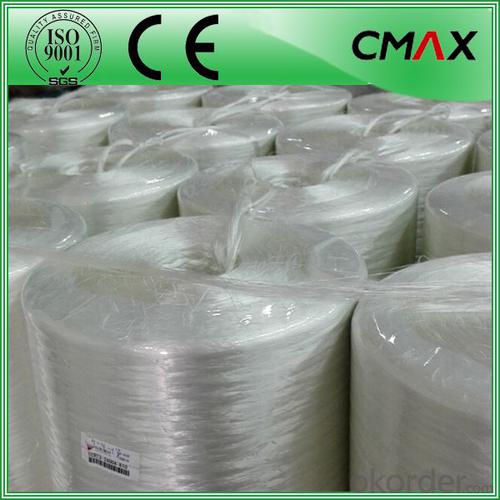

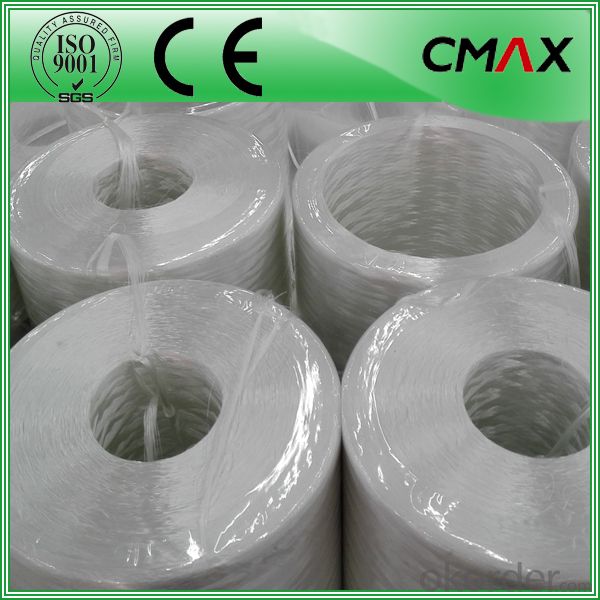

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How thick is fiberglass mat tissue typically?

- Fiberglass mat tissue, also known as fiberglass mat or simply mat, typically comes in various thicknesses depending on its intended use. The thickness can range from 0.5 millimeters (mm) to as thick as 3 mm. However, the most commonly used thicknesses for fiberglass mat tissue are 1.5 mm and 2 mm. These thicknesses are ideal for applications such as reinforcing laminates, composite materials, and providing surface finishes. It is important to note that the specific thickness of fiberglass mat tissue may vary depending on the manufacturer and the specific requirements of the project.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in commercial buildings?

- Insulation in commercial buildings can be achieved using fiberglass mat tissue. This material is commonly utilized due to its exceptional thermal performance, durability, and cost-effectiveness. Typically composed of fine glass fibers bonded with resin, the mat can be applied to various surfaces such as walls and ceilings to enhance energy efficiency by minimizing heat transfer. Proper insulation is vital in commercial buildings to maintain a comfortable indoor environment and reduce energy usage. Fiberglass mat tissue offers numerous benefits for insulation purposes. It possesses low thermal conductivity, effectively resisting heat flow and diminishing heat loss or gain through the building envelope. This results in lower energy expenses and improved temperature control. Furthermore, fiberglass mat tissue is lightweight and easy to install, making it a convenient option for commercial buildings. It can be easily cut and shaped to fit around obstacles, ensuring a secure seal and preventing air leakage. This further enhances the effectiveness of the insulation. Moreover, fiberglass mat tissue is non-combustible, providing an added safety advantage in commercial buildings where fire protection is paramount. It does not contribute to the spread of flames and its fire resistance properties assist in containing fires and offering valuable escape time during emergencies. Overall, fiberglass mat tissue is a suitable and widely utilized insulation material in commercial buildings. Its thermal performance, ease of installation, and fire resistance make it a dependable choice for achieving energy efficiency and comfort in commercial spaces.

- Q: Can fiberglass mat tissue be used for roofing?

- Yes, fiberglass mat tissue can be used for roofing. Fiberglass mat tissue is a type of material that is commonly used in the construction industry for various purposes, including roofing. It is known for its durability, strength, and ability to withstand harsh weather conditions. Fiberglass mat tissue is often used as a reinforcement layer in roofing systems, providing additional strength and stability to the roof. It helps to improve the overall performance and longevity of the roof by offering excellent resistance to water, fire, and other external factors. Additionally, fiberglass mat tissue is lightweight and flexible, making it easier to handle and install on roofs of different shapes and sizes. Overall, fiberglass mat tissue is a suitable choice for roofing applications due to its superior properties and performance.

- Q: What is fiberglass mat tissue made of?

- Fiberglass mat tissue is made of fine strands of glass fibers that are bonded together with a resin or binder material.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q: Is fiberglass mat tissue resistant to acids?

- Yes, fiberglass mat tissue is generally resistant to acids. Fiberglass is known for its excellent corrosion resistance properties, and this includes resistance to various acids. The combination of fiberglass mat and resin creates a strong and durable material that can withstand exposure to a wide range of chemicals, including acids. However, it is important to note that the specific type and concentration of acid can still affect the resistance of fiberglass mat tissue. In some cases, certain highly concentrated or aggressive acids may cause damage or degradation to the material over time. Therefore, it is always advisable to consider the specific acid being used and consult the manufacturer's recommendations for compatibility before exposing fiberglass mat tissue to any acidic environment.

- Q: What are the different reinforcement patterns available for fiberglass mat tissue?

- Fiberglass mat tissue offers various reinforcement patterns, each with its unique benefits and characteristics. 1. Random Chopped Strand Mat (CSM) is widely utilized and consists of randomly chopped fiberglass strands held together with a binder. It boasts good strength and stiffness properties, making it suitable for a wide range of applications. 2. Continuous Strand Mat (CSM) features evenly distributed continuous fiberglass strands bound together with a binder. It offers enhanced strength and stiffness compared to random chopped strand mat, making it perfect for high-performance applications. 3. Woven Roving comprises interwoven bundles of fiberglass yarns and provides exceptional strength and impact resistance. It is ideal for applications that require high load-bearing capabilities. 4. Multiaxial Fabrics consist of multiple layers of fiberglass fibers oriented in different directions, offering balanced strength properties in multiple directions. This makes it perfect for applications that require isotropic properties. 5. Stitch-Bonded Fabrics are created by mechanically stitching together layers of fiberglass fibers. They offer good drapability and conformability, making them suitable for complex shapes or curved surfaces. 6. Knitted Fabrics are made by interlocking loops of fiberglass yarns, providing excellent flexibility and ease of handling. They are suitable for applications that require conformability and flexibility. Each reinforcement pattern possesses its own advantages and is utilized in various applications based on specific requirements such as strength, stiffness, impact resistance, flexibility, or conformability. It is crucial to select the appropriate reinforcement pattern based on desired end-use properties and the manufacturing process.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Yes, fiberglass mat tissue can be used for making lightweight stairs. Fiberglass mat tissue is a thin, lightweight material that is made from randomly oriented glass fibers bonded together with a resin. It is commonly used in construction and manufacturing industries due to its strength, durability, and lightweight properties. When used in the production of stairs, fiberglass mat tissue can be layered and molded to create a lightweight yet strong structure. This material has excellent tensile strength and dimensional stability, making it suitable for supporting the weight of individuals using the stairs. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and UV rays, making it ideal for outdoor or high-moisture environments. It is also fire-resistant, which adds to the safety aspect of using it for stairs. Overall, fiberglass mat tissue is an excellent choice for making lightweight stairs as it combines strength, durability, and resistance to various environmental factors.

- Q: Can fiberglass mat tissue be used for reinforcing concrete structures?

- Indeed, fiberglass mat tissue can be utilized to fortify concrete structures. This material, crafted from woven glass fibers, is thin and lightweight. It boasts a commendable strength-to-weight ratio and exceptional resistance to corrosion, rendering it an optimal selection for reinforcing concrete structures. When employed as reinforcement in concrete, fiberglass mat tissue is typically embedded within the concrete mixture. This inclusion aids in enhancing the concrete's tensile strength and ductility, effectively preventing cracks and augmenting its overall durability. Fiberglass mat tissue is frequently employed in various applications, including precast concrete panels, concrete pipes, and concrete overlays. These structures benefit from the reinforcement provided by fiberglass mat tissue, enabling them to endure heavy loads and resist cracking, particularly in areas where concrete alone may prove inadequate. Additionally, fiberglass mat tissue exhibits resistance to chemicals and environmental elements, qualifying it for use in harsh conditions or exposed surroundings. It does not succumb to corrosion or rust like traditional steel reinforcements, ensuring the longevity and structural integrity of the concrete structure. In conclusion, fiberglass mat tissue stands as a dependable and efficient choice for reinforcing concrete structures. Its lightweight nature, impressive strength, corrosion resistance, and durability have solidified its status as a popular option within the construction industry.

Send your message to us

Glass Fiber Roving Assembled Multi End Fiberglass Roving for Gypsum Mouldings

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords