GK120 Steel Frame Formwork-Column Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

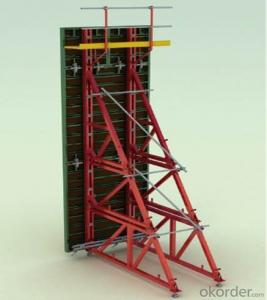

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

Send your message to us

GK120 Steel Frame Formwork-Column Formwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords